UKAM Industrial Superhard Tools

About the company

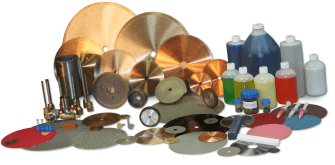

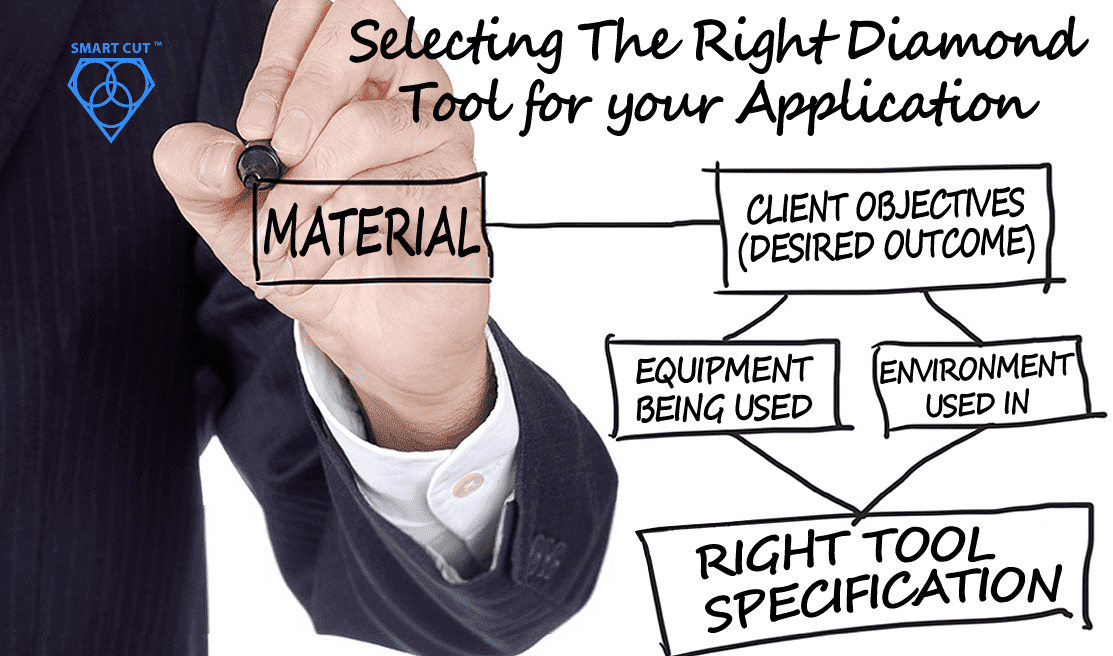

UKAM Industrial Superhard Tools is a small American High Technology, Specialty, Diamond Tool & Equipment Manufacture. We produce precision Sintered (metal bond), Hybrid Bond, Resin Bond Electroplated, Braised Bond, Vetrified Bond, diamond & CBN tools.

As well as equipment & solutions for a large variety of applications, materials, and industries.

Specializing in High Precision & Ultra Thin Diamond Slicing, Dicing, & Wafering Blades 0.5″ to 72″ Diameter, starting .001″ Thick. Diamond Drills & Accessories from .001″ to 48″ in Diameter. We produce Advanced Standard & Custom Diamond & CBN Tools & Solutions for the complex material world.

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

PRODUCTS & SOLUTIONS

By Industry

PRODUCTS & SOLUTIONS

Diamond & CBN Tools

Diamond Core

Drills

Diamond Drills, Core Drills, & Form Tools from .001″ to 48″ Diameter, & Drilling Accessories for drilling just about any...

Diamond Dicing

Blades

Diamond Dicing Blades from 0.5″ (12.7mm) to 6″ (154mm) in Diameter, starting from .001″ (25 microns) thick...

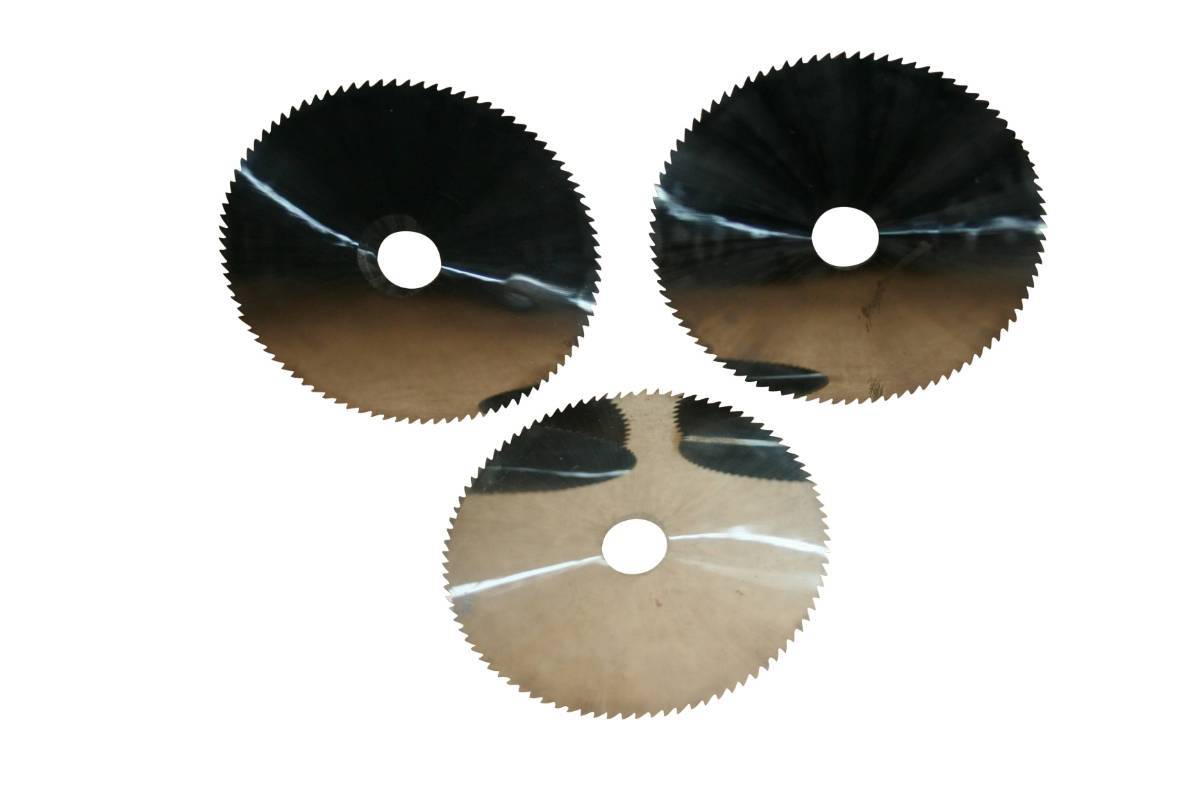

Ultra Thin & High Precision Diamond CBN & Blades

Ultra Thin & High Precision Diamond & CBN Blades from 0.5″ (12.7mm) to 48″ (1,219mm) diameter, starting...

Diamond Routers, Diamond Points, Profile Tools & Milling Tools

Large variety of diamond & cbn tools from stock and made to your specification using all bond types. Tools include...

Diamond Micro DrillS & Micro Tools

Micro Diamond Drills are available from .001″ to .035″ in diameter (25 microns and up)...

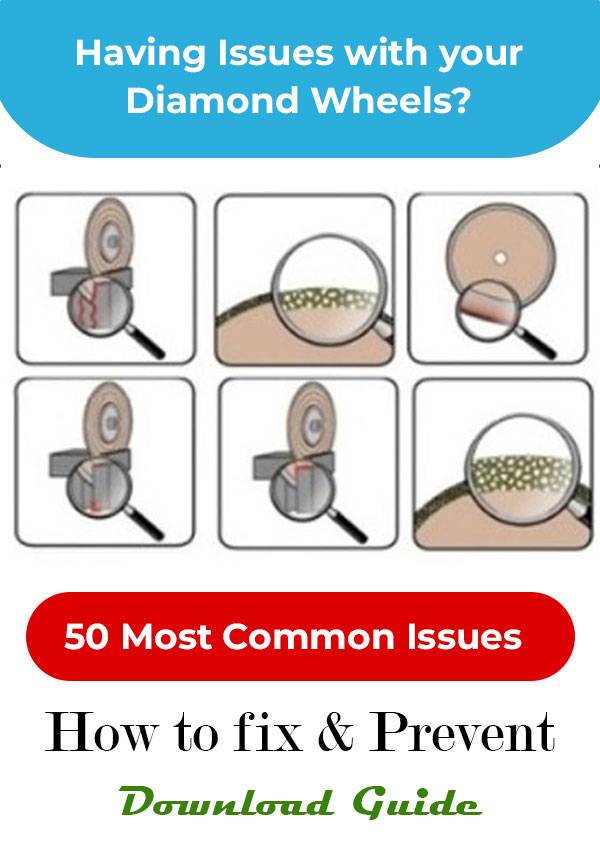

Diamond & CBN

Wheels

Diamond Wheels and Discs for virtually any application. Whether you are looking for ultra fine finish grinding of exotic material...

Custom Diamond & CBN

Tools

Thousands of diamond tools are available from stock for immediate delivery. Just about any diamond tool can be designed and...

Diamond Discs &

Laps

Diamond & abrasive grinding, polishing and lapping solutions for many industries and applications for clients in Industry, R&D, and hobby/craft...

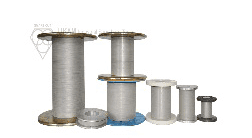

Diamond Wire

Blades

Diamond wire blades made to order from 0.12mm TO 0.42mm diameteravailable for any spool for juat about any wire saw...

Diamond Band Saw

Blades

Diamond Band Saw Blades made to order to your specifications, available in any length width...

Diamond

Consumables

Large Variety of Diamond & CBN Suspension, Paste, Slurry, and Powders are available in Monocrystalline, Polyscrstalline, & Natural Diamond. Used...

Consumables For Sample Preparation Metallography & Materials Research

Consumables for materials preparation, metallography, quality control, materials research. For sectioning, rough grinding, fine grinding, polishing...

Diamond Tool

Accessories

Accessories include: coolants, dressing sticks, flanges, wheel stiffeners, water swivel and shank adapters.

Precision

Abrasives

Larger variety of precision abrasives for sample & surface preparation. Abrasive Cut Off Blades, Discs, Rolls, Belts, Wheels, Film, Powders,

Diamond Tools For

Concrete & Construction

High quality standard and custom tools for contractors. Our tools provide higher level of performance compared to what is typically

Diamond Dressers

Dressing Tools for For truing and dressing of conventional abrasive grinding wheels. Single point, multi point, chisel shape, straight, angle

Ultra Thin, High Precision & Micro Carbide Tools

Tungsten carbide micro drills, micro tools and ultra thin & high precision cutting blades from stock and custom manufactured to

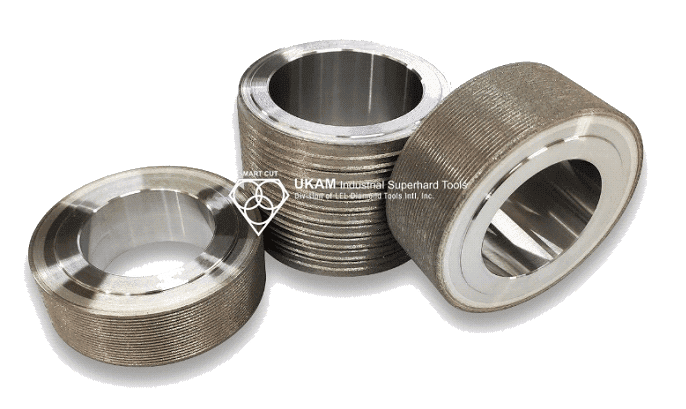

Diamond Rotary

Dressers

Diamond rollers are used to form grinding wheels for many different kinds of mass production. Shorter dressing time and long

Precision Machining

Services

We offer large variety of of services including: Dicing, Slicing, Sectioning, Drilling, Coring, Micro Drilling, Grinding, Polishing, & Machining

Process

Development

Experienced Engineers and Application Laboratory, Equipped with some of the latest Slicing, Dicing, Wafering, Drilling, & Micro Drilling Equipment is

Precision Cutting

Saws

Precision Cutting Machines for Laboratory & Industry. Used in Research and Development, Quality Control, Failure Analysis, Materials Research, & Industrial

Grinding & Polishing

Equipment

Grinding & Polishing Equipment for Laboratory & Industry. Used in Research and Development, Quality Control, Failure Analysis, Materials Research, &...

PRODUCTS & SOLUTIONS BY BOND TYPE

Diamond & CBN Tools

SMART CUT®

Technology

Advanced technology that redefines the standard. Every diamond or cbn crystal evenly positioned oriented in open bond matrix. Each crystal...

Sintered (Metal Bond)

Diamond

Many types and forms of sintered (meta bond) diamond cbn tools are available from stock custom manufacturing. Diameters from small...

Electroplated Diamond &

CBN Tools

we manufacture multi layered electroplated tools. They have 3 layers of diamonds, not just 1 layer of diamonds like conventional...

Resin Bond Diamond &

CBN Tools

we manufactured resin bond tools with advanced molding process. Available in a large variety of diamond, thicknesses, arbor/mandrel sizes, geometries...

Hybrid Bond Diamond &

CBN Tools

HYBRID BOND Tools exhibit provide long life, maintaining superior form, shape, while consistently delivering excellent surface finish. These tools are...

Braised Bond Diamond &

CBN Tools

Braised Bond Diamond Tools are perfect for machining tough- to-cut materials where fast stock removal and deep cuts are required...

Vitrified Bond Diamond &

CBN Tools

Fired Ceramic Bond matrix, which is very brittle and porous. Also known as ceramic bond. Based on fusible glasses combined...

PCD & PCBN (Polycrystalline Diamond Tools)

PCD PCBN Tools for wide variety of industries applications. Available from stock custom manufacturing to fit your requirements. PCD Micro...

CVD (Chemical Vapor Deposition) Diamond Tools

Standard & Custom (CVD) Chemical Vapor Deposition Diamond Tools. Used for graphite, carbon, green ceramic, carbon fiber, reinforced polymers, fiberglass...