Select right Diamond Dicing Blade for your application

-

Posted by

Leon Meyer

Leon Meyer

Table of Contents

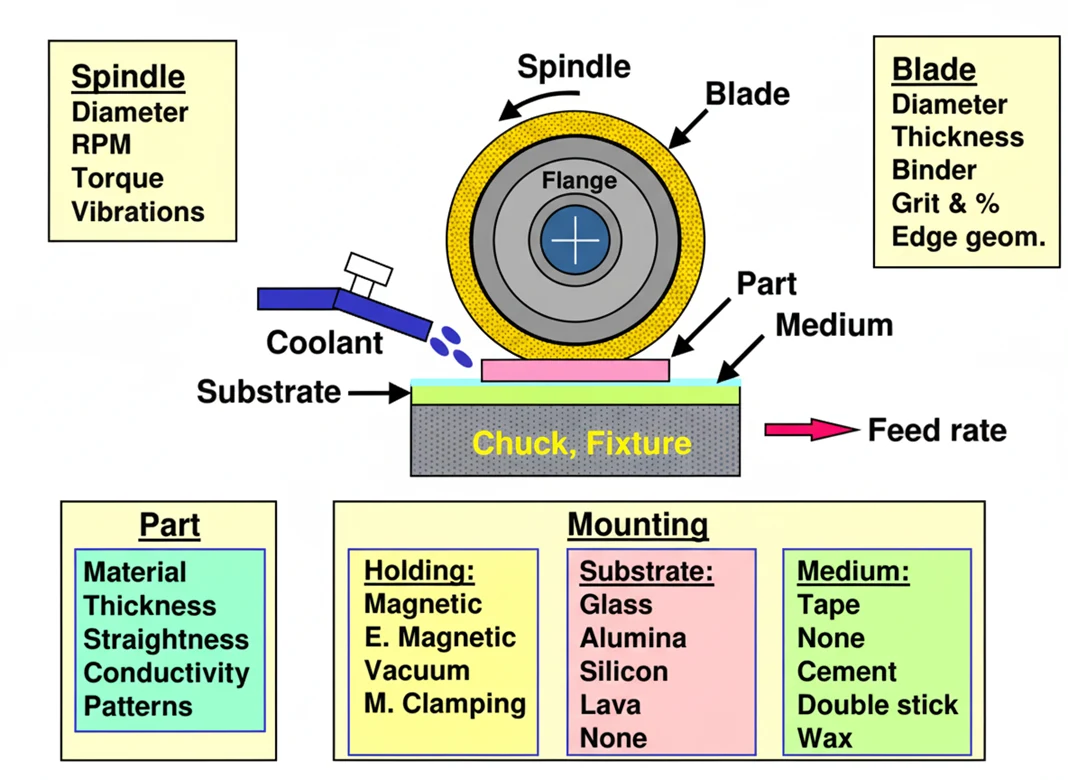

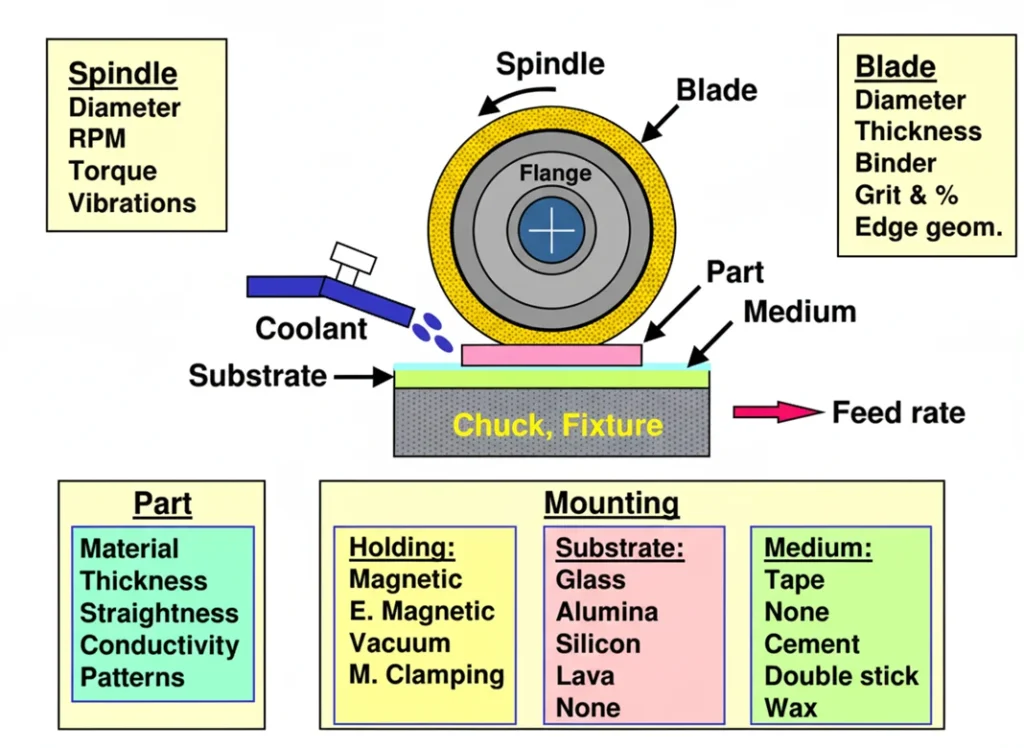

ToggleSelecting the right dicing blade for your application requires careful consideration of several key variables that influence both performance and cost. The type of material being cut, the depth of the required cuts, the level of cut quality, the equipment used and its operating speed, and the overall production output all play a direct role in determining the most suitable blade. These parameters affect blade bond or binder, blade thickness, and diamond grit size. Other factors such as blade dressing, exposure, feed rate, spindle speed, and coolant supply in the dicing zone must also be taken into account to achieve consistent and repeatable results.

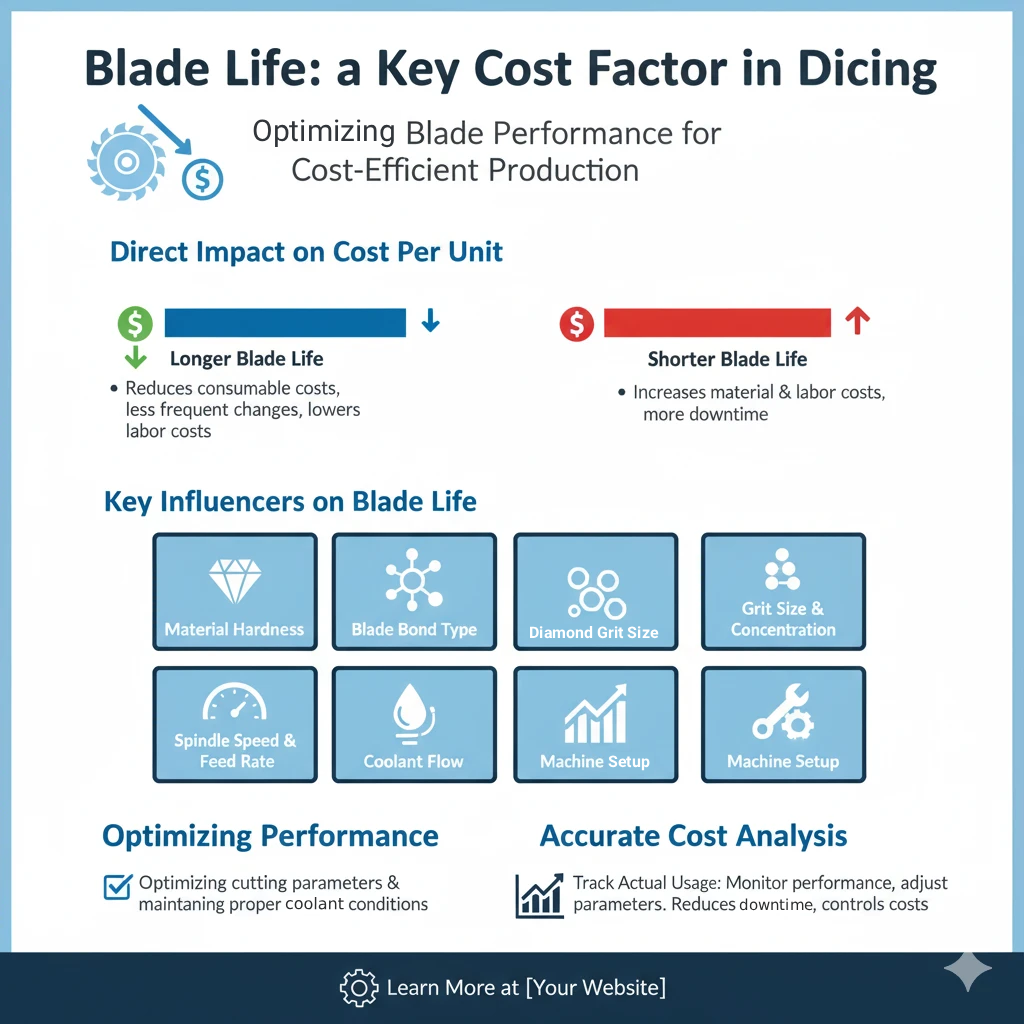

When making a selection, it is important to remain objective and weigh all parameters equally. While many users focus primarily on blade life and cut quality, other considerations often have equal or greater impact on the overall efficiency of the process. Consistency of performance, unit cost, lead time, availability, and technical support should not be overlooked. Ignoring these can lead to higher long-term costs and production issues even if initial blade life appears sufficient.

Understanding the capabilities of your dicing machine is essential for aligning with your objectives. Knowing what your machine can and cannot do will help you set realistic goals and avoid operational issues. Advanced machines with higher precision may be necessary for cutting materials that require very tight tolerances.

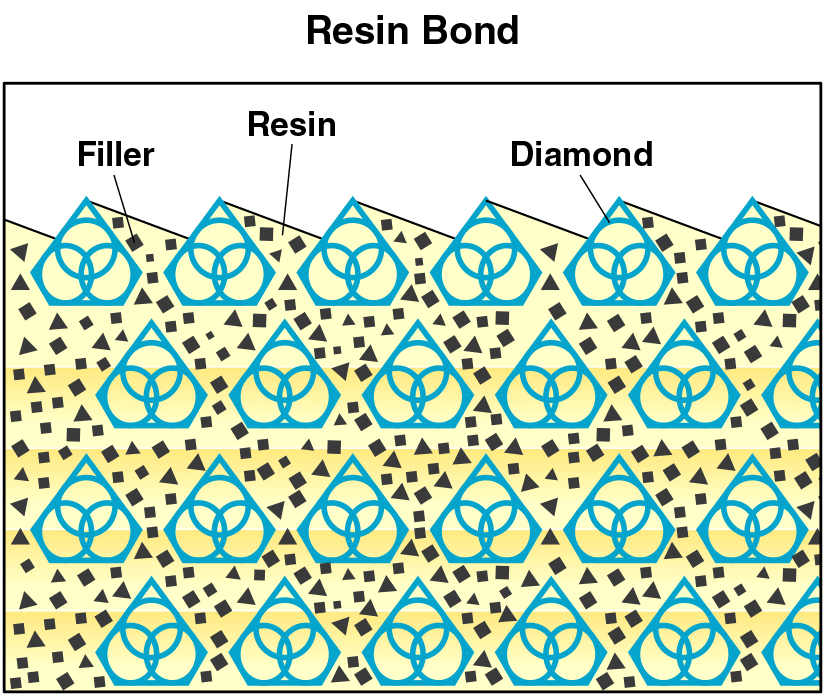

Blade selection is critical and should align with your material and cutting objectives. The type of dicing blade chosen, such as resin bond or nickel bond, affects cut quality and operational efficiency. For applications requiring smooth, precise cuts with minimal chipping, a resin-bonded blade might be more suitable.

To align objectives with operational preparation, define specific goals by clearly outlining what you need to achieve, whether it is a high yield, minimal material wastage, or the finest precision cuts. Assess the material properties to understand the material’s characteristics and how they affect the dicing process. Evaluate machine specifications to ensure your dicing equipment can meet the operational demands set by your objectives. Select appropriate equipment, choosing blades and fixtures that align with both the material properties and the operational goals. Finally, set parameters based on your objectives, including the appropriate cutting parameters such as spindle speed, feed rate, and cooling methods.

Consistency is best measured through yield. Yield represents the measurable output of the blade, such as the number of wafers, packages, or linear meters cut before variations in quality appear. For example, if a blade is designed to last for 25,000 cuts but inconsistencies begin at 18,000 cuts, the deviation from expected yield introduces problems in both production and quality control. Operators may attempt to recover lost life by adjusting parameters, but this requires time and additional monitoring. The more inconsistent the blade becomes, the more attention the operator must devote to the process, taking away valuable time from monitoring other machines or operations.

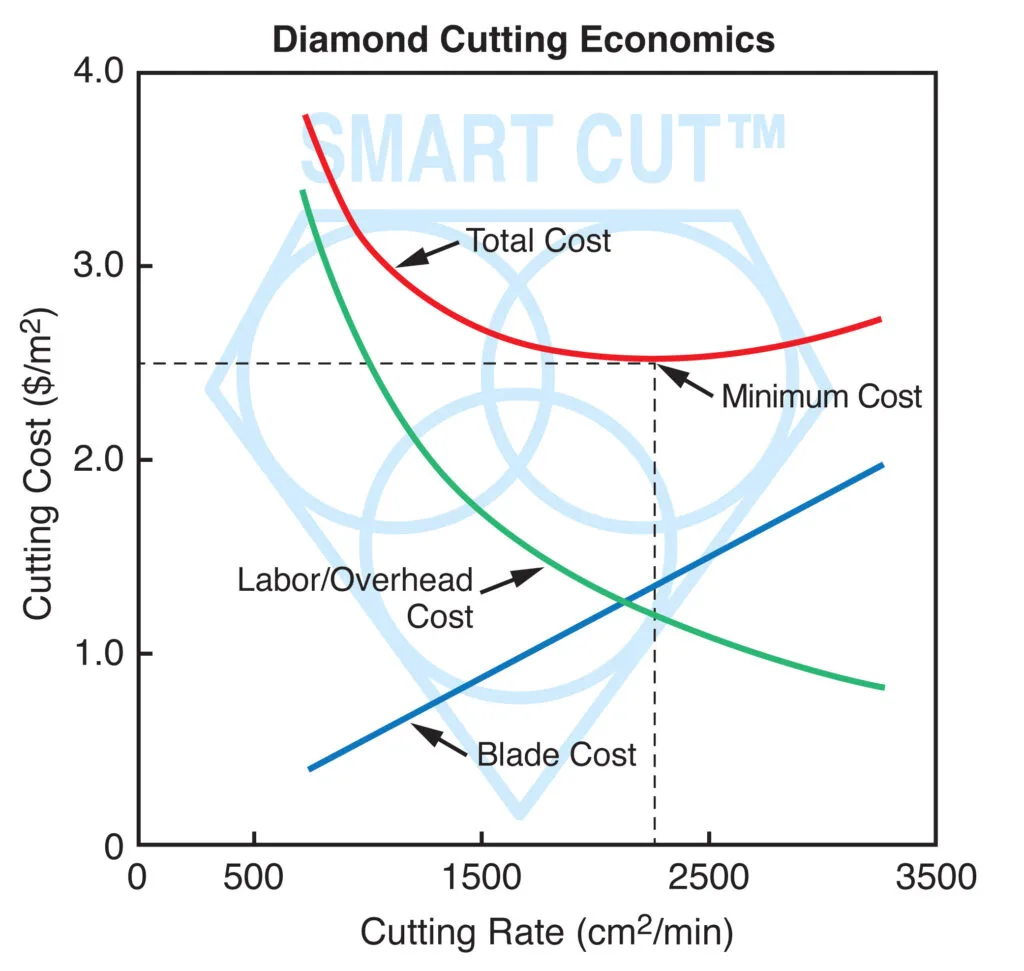

Cost analysis must go beyond the initial purchase price. A true evaluation should consider the cost per linear millimeter cut. A blade priced at $18,000 that cuts 100,000 millimeters results in a cost of $0.00018 per millimeter, while another blade priced at $22,000 that cuts 150,000 millimeters has a lower actual cost of $0.00016 per millimeter. Although the second blade is more expensive upfront, it delivers greater total yield, reduces the frequency of blade changes, and lowers the labor associated with setup and downtime. The result is not only cost savings but also improved process stability.

A well-chosen dicing blade balances material compatibility, cut quality, yield, cost efficiency, and operational simplicity. Each application may place different weight on these parameters, but evaluating them together provides a clearer picture of which specification will offer the best overall value. By focusing on yield, consistency, and cost per cut rather than just initial price or expected life, you ensure that the blade supports both productivity and quality in your specific operation.

Key Variables in Dicing Blade Selection

Material to be cut

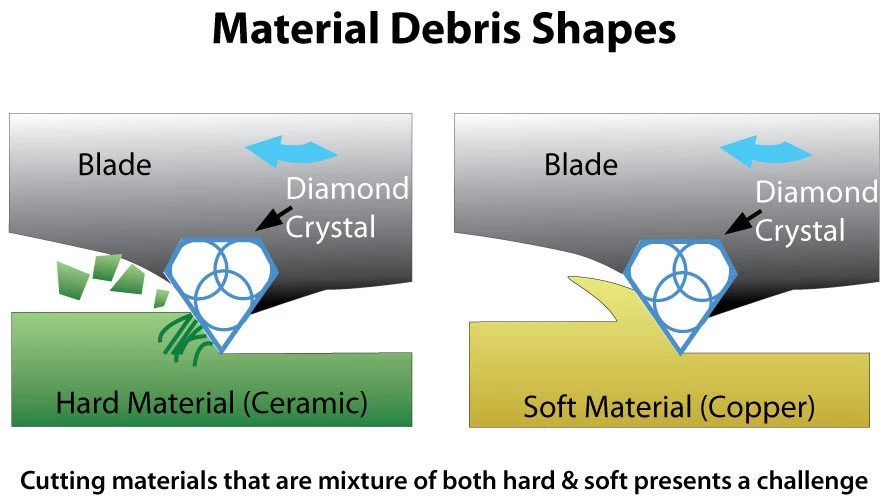

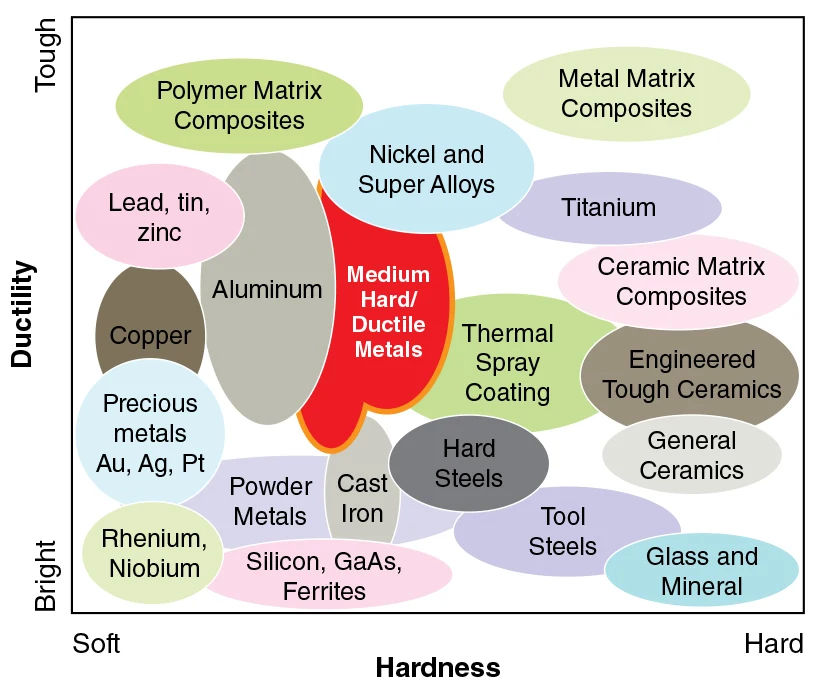

The material you plan to cut plays one of the most important roles in selecting the correct dicing blade. Every material has unique properties such as hardness, brittleness, abrasiveness, and thickness that directly influence blade selection. Choosing the wrong blade type can result in poor cut quality, short blade life, or even damage to the workpiece and equipment.

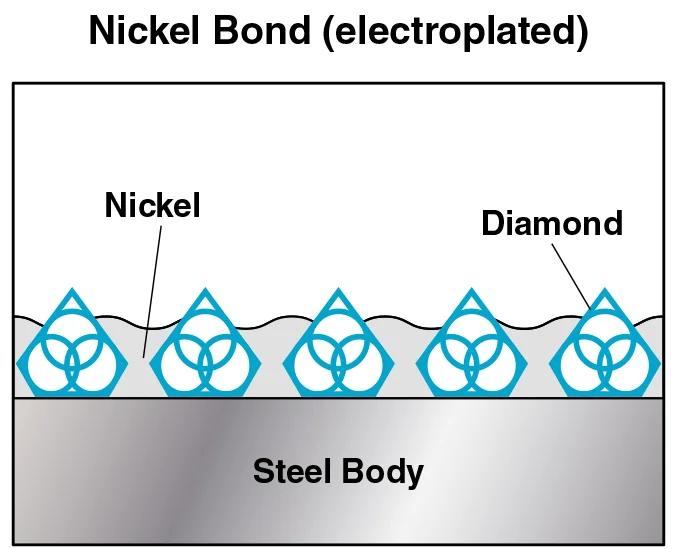

If you are dicing ultra-hard and brittle materials such as alumina or sapphire, a soft bond, thin-kerf dicing blade like a resin bond blade is typically recommended. A soft bond allows the diamond particles to break free more easily, exposing new sharp edges and enabling freer, faster cutting with reduced chipping. On the other hand, if you are cutting softer materials or very thin substrates and wafers, a nickel bond diamond dicing blade may be the better choice. Nickel bond blades provide stronger diamond retention, allowing for excellent precision and longer life when cutting materials that do not wear the bond as aggressively.

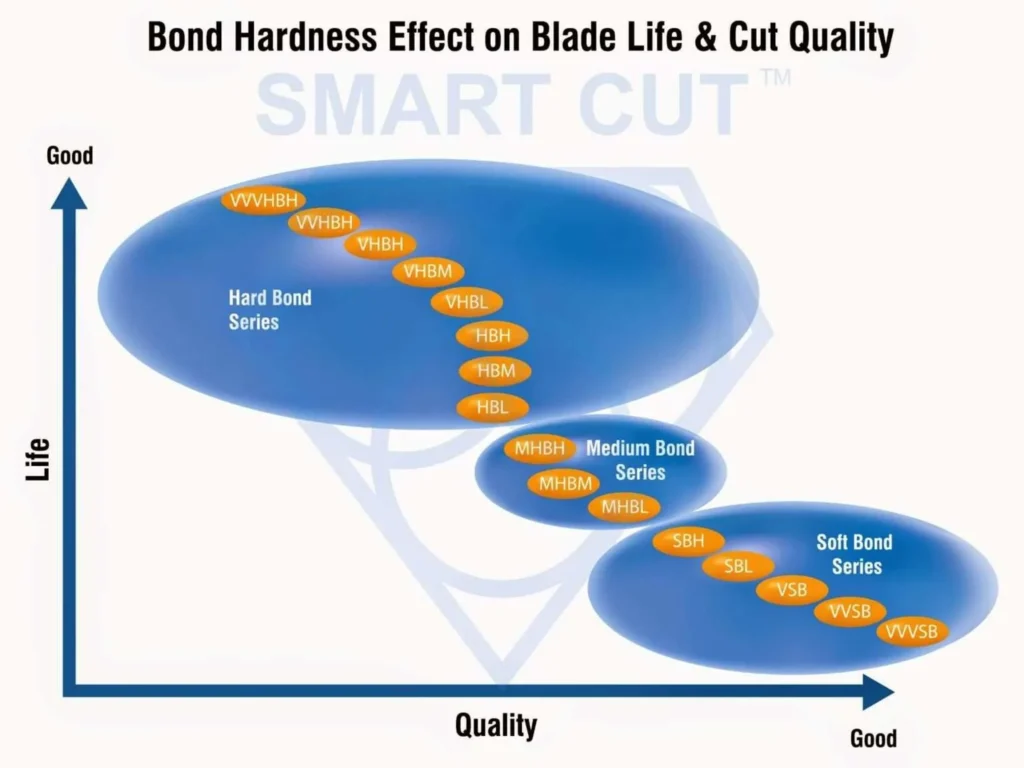

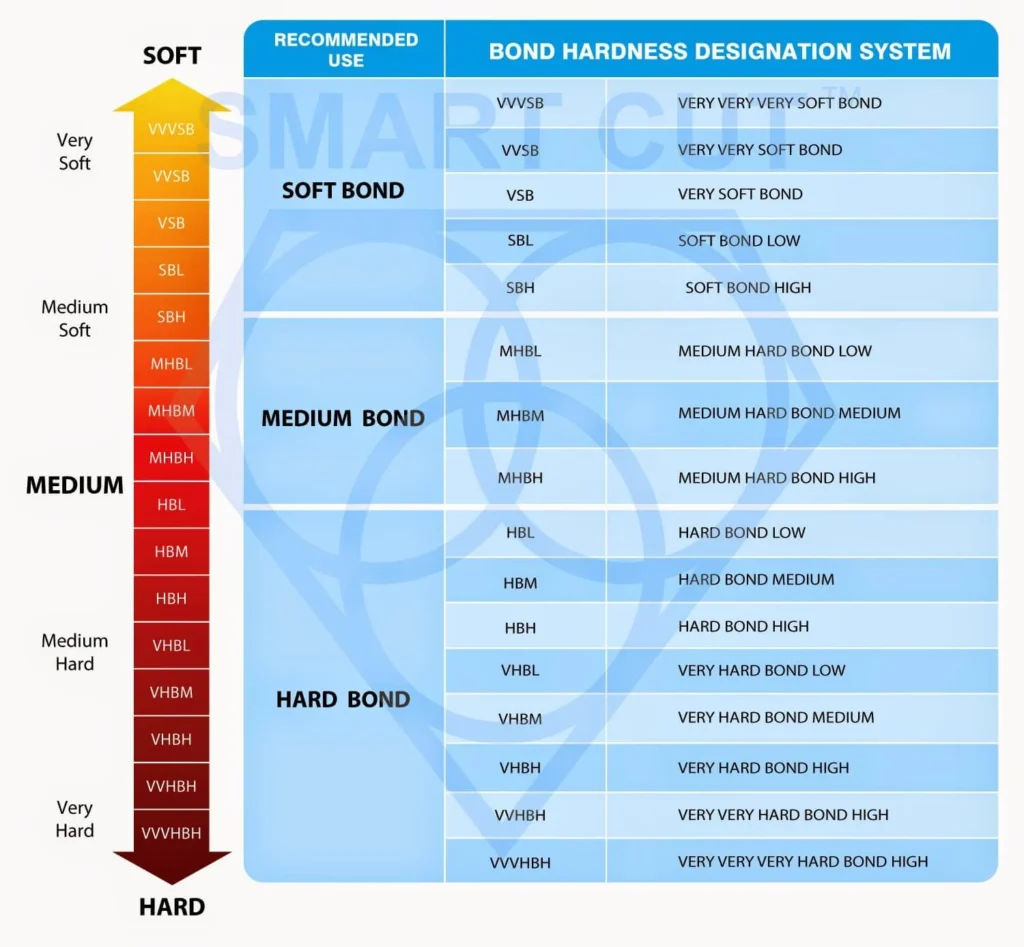

Material hardness is a primary factor in blade choice. Hard and brittle materials require a softer bond matrix so the blade remains sharp by constantly exposing new diamond edges. Softer or more abrasive materials require a harder bond matrix so the diamonds are held in place longer, extending blade life. Hard bond blades rely on very hard diamond particles to keep sharpness over long runs. Hardness itself is the resistance of a material to deformation and is measured on different scales such as Mohs, Vickers, and Knoop. Understanding where your material falls on these scales is critical in choosing the right bond type.

Material thickness also plays a crucial role. It determines the blade diameter, blade thickness, exposure ratio, bond type, diamond grit size, and concentration needed for efficient cutting. A thicker material may require a larger diameter blade with greater exposure, while thinner materials may demand smaller, ultra-thin blades with tighter tolerances.

Depth of cut must always be balanced with blade geometry. Using a blade that is too thin for a deep cut can cause blade deflection, excessive wear, and poor cut quality. For example, cutting a 0.050″ thick alumina substrate with a 0.0040″ thick blade is not recommended because the blade is too thin for such a depth. This mismatch leads to deflection and reduced accuracy. Selecting the proper exposure and blade thickness ensures stability during cutting and helps maintain consistent results.

In practice, matching the right blade to the material means evaluating bond type, blade geometry, grit size, concentration, and exposure together. For brittle, high-value materials such as sapphire, silicon carbide, and ceramics, the emphasis should be on minimizing chipping and subsurface damage. For softer substrates, the priority shifts to maximizing precision, yield, and blade life. The goal is always to achieve the cleanest cut, longest blade life, and lowest overall cost per cut by tailoring blade specifications to the exact characteristics of the material.

Material Structure and Grain Orientation

Material structure and grain orientation strongly influence how a diamond dicing blade performs. Materials with isotropic properties like glass cut evenly in all directions, but anisotropic materials such as sapphire, silicon carbide, or advanced ceramics behave differently depending on their crystal plane or grain alignment. A blade that works well on one orientation may produce excess chipping, deflection, or premature wear on another.

In single-crystal materials like sapphire or quartz, certain crystallographic planes are more prone to cracking, requiring careful selection of bond type, grit size, and cutting parameters. In polycrystalline ceramics, grain boundaries can weaken the structure and increase micro-cracking if the wrong blade is used. For composites, the challenge is even greater because fibers and matrices respond differently to the cutting force.

Choosing the right dicing blade means accounting for these structural differences. Finer grit blades with softer bonds are often better for materials with directional fracture tendencies, while harder bonds with coarser grits may be needed for abrasive, multi-grain structures. Properly matching the blade to material orientation helps control crack propagation, reduces edge chipping, and improves yield.

Material Value and Yield Requirements

Material value and yield requirements play a decisive role in selecting the right diamond dicing blade. When cutting high-value wafers or substrates such as semiconductors, sapphire optics, or piezoelectric crystals, the priority is usually maximizing yield and protecting the material rather than achieving the fastest cutting speed. Even minor edge chipping or subsurface damage can lead to rejected parts, lower yields, or downstream failures, which cost far more than the blade itself.

For these applications, it is often better to use a thinner kerf blade to minimize material loss, a higher grit size to produce smoother edges, and a softer bond matrix to maintain sharp cutting action. While this approach may reduce overall blade life, the trade-off is justified because it delivers higher quality cuts, reduced scrap rates, and greater process consistency.

In contrast, for lower-value or less delicate materials where yield is not as critical, a blade with longer life and higher throughput may be preferable, even if cut quality is not as refined. Balancing these requirements ensures that the blade specification aligns not only with the material but also with the economic priorities of the application.

Thermal Sensitivity of Materials

Thermal sensitivity of materials is an important consideration when selecting diamond dicing blades. Certain materials such as quartz, lithium niobate, and advanced composites are highly prone to thermal stress. Even small increases in cutting temperature can result in micro-cracks, warping, or dimensional instability, which directly reduce yield and part reliability.

When working with these materials, the blade specification must help manage heat. A softer bond blade is often preferred because it exposes new sharp diamond edges more frequently, reducing friction and heat buildup. Finer grit sizes can also lower cutting forces, which helps limit thermal stress. At the same time, adequate coolant supply and delivery to the dicing zone is critical to maintaining temperature control.

If the wrong bond type or inadequate coolant flow is used, excessive heat can accumulate at the cutting edge, damaging both the material and the blade. This not only shortens blade life but also increases the risk of inconsistent cuts and downstream processing issues. Selecting a blade with the proper bond hardness, grit size, and exposure for thermally sensitive materials ensures stable cutting, minimal thermal damage, and higher yields.

Abrasiveness of the Material

Abrasiveness of the material greatly influences the performance and life of diamond dicing blades. Materials such as graphite, fiberglass, and silicon carbide are highly abrasive and can rapidly wear down the bond matrix. If the blade bond is too soft, diamonds will release too quickly, leading to premature blade wear, inconsistent cutting, and higher replacement costs.

For these applications, a harder bond dicing blade is the better choice. Harder bonds provide stronger diamond retention, allowing the diamonds to remain in place longer and withstand the abrasive action of the material. This maintains sharpness over extended runs and ensures consistent cut quality. In addition, coarser diamond grits may be used in some cases to improve cutting efficiency and reduce the load on each individual particle.

Selecting the right bond hardness for abrasive materials ensures that the blade maintains stability and productivity over its full operating life. The correct blade not only withstands the material’s abrasive nature but also reduces downtime for blade changes, helping achieve lower cost per cut and more reliable production results.

Surface Finish and Edge Integrity Requirements

Surface finish and edge integrity requirements are often the deciding factor when selecting diamond dicing blades. In applications where ultra-smooth surfaces and precise edge quality are critical, such as in optical components, medical devices, and high-frequency electronics, the blade must deliver flawless results with minimal chipping or subsurface damage. Even small imperfections can lead to poor optical clarity, device failure, or signal loss, making surface finish just as important as yield.

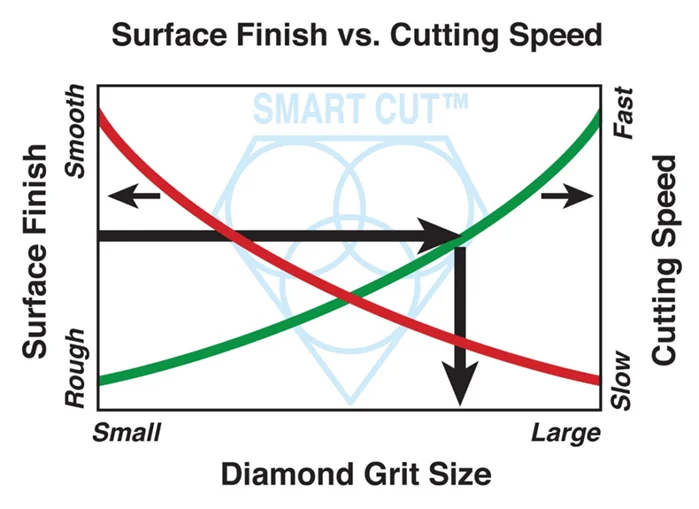

For these situations, finer grit diamond blades with softer resin bonds are preferred. Finer grit produces smoother edges, while the softer bond constantly exposes new sharp diamond particles, reducing cutting forces and improving surface quality. Although these blades typically have shorter life and slower cutting speeds, the trade-off is worthwhile when the application demands superior finish and precision.

In contrast, when edge quality is less critical—such as with mechanical parts or low-cost substrates—coarser grit and harder bond blades may be used to maximize cutting speed and blade life. The key is balancing the requirements of the final product with the blade’s cutting characteristics. For high-value and precision-driven applications, the priority remains clear: consistent, defect-free surfaces and near-perfect edge integrity.

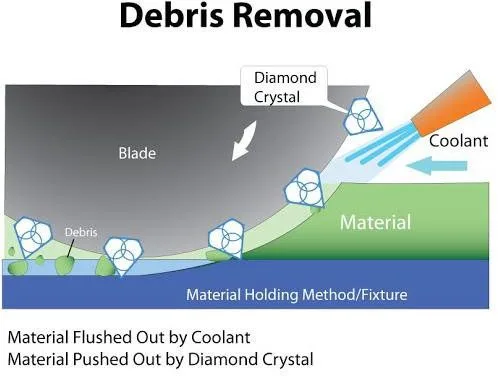

Coolant Interaction with the Material

Coolant interaction with the material is another important factor in selecting diamond dicing blades. Some materials, including certain ceramics, composites, and porous substrates, can react chemically with coolants or absorb them during cutting. This may alter cut quality, cause swelling, chemical attack, or contamination, and in some cases lead to long-term reliability issues in the finished part.

When dicing sensitive materials such as lithium niobate, specialty glasses, or porous ceramics, it is critical to match the blade and coolant to the material. A blade with the wrong bond type or grit size may generate excessive heat or require aggressive coolant flushing, both of which increase the risk of interaction. Using the proper water-soluble or low-residue dicing coolant ensures that chips are flushed efficiently without penetrating or damaging the material surface.

The choice of blade and coolant should always be considered together. A softer bond blade can reduce friction and lower the amount of heat generated, minimizing coolant reactivity. Meanwhile, a balanced coolant supply at the dicing zone helps maintain stable cutting temperatures, prevents loading of the blade, and avoids introducing stress into sensitive materials. By pairing the right dicing blade with the appropriate coolant type and delivery method, you reduce the risk of contamination, improve surface quality, and ensure higher process reliability and yield.

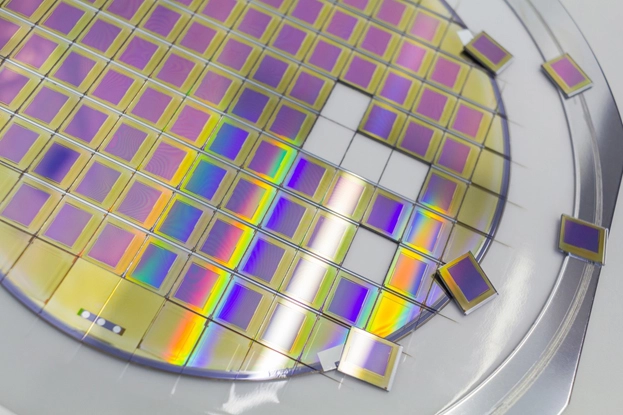

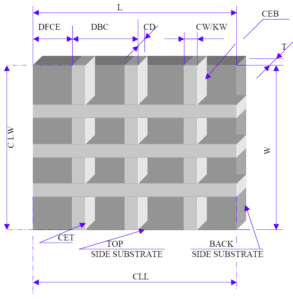

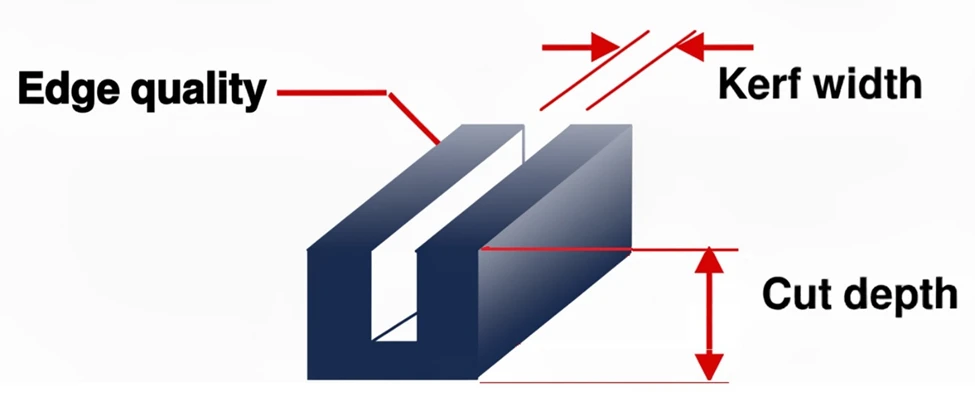

Kerf Width vs. Material Waste

Kerf width vs. material waste is a key factor when choosing diamond dicing blades, especially for applications involving ultra-thin wafers or high-value substrates. Every micron of kerf removed during cutting represents lost material, which becomes significant when processing expensive components such as semiconductors, sapphire optics, or specialty ceramics. In these cases, the goal is to minimize waste while still maintaining cut quality and process stability.

Using a blade with a thinner kerf reduces material loss and allows for a higher number of dies or usable parts per wafer. This directly improves yield and lowers overall production cost. However, thinner blades also require careful consideration of bond type, diamond concentration, and exposure length. If the blade is too thin for the material thickness or cut depth, it may deflect, wear prematurely, or produce inconsistent results.

For thicker or less expensive materials where yield is not as critical, a slightly wider kerf blade may be more practical. Wider blades offer greater rigidity and stability, which reduces the risk of deflection and helps maintain straight cuts at deeper depths. The trade-off is slightly more material loss, but this is often acceptable when overall throughput and blade life are the main priorities.

Balancing kerf width with material value, thickness, and required cut depth ensures the best results. For high-cost substrates, the priority is clear: use the thinnest stable kerf possible to maximize usable material. For general-purpose applications, stability and blade life may take precedence, allowing for a modest increase in kerf width to achieve faster cutting and lower operating costs.

Dicing Desired Outcome

When selecting the right dicing blade for your application, the starting point should always be the desired outcome. Every process requirement translates into blade characteristics that directly influence cut quality, kerf width, surface finish, edge chipping, and cost per part.

If the priority is cut quality, you will need a blade that matches the material type and thickness with the proper bond, grit size, and concentration. Finer grit blades generally deliver smoother and more controlled cuts, while optimized bond hardness ensures consistent performance throughout the blade life. For precision semiconductor and MEMS applications, this is the defining factor.

When focusing on kerf width, the choice comes down to blade thickness. A thinner kerf preserves more material, increases die yield, and minimizes waste, which is critical for high-value wafers and optical substrates. Thinner kerfs, however, require careful control of spindle setup and flange support to maintain stability and prevent blade deflection.

Surface finish is controlled by the interaction of grit size, bond type, and feed rate. Finer grit sizes and resin bond blades often deliver smoother finishes with less subsurface damage, which is essential for optical glass, sapphire, and advanced ceramics. In contrast, coarser grits and harder bonds cut faster but can leave more pronounced marks on the surface.

Edge chipping is one of the most common quality challenges in dicing. To minimize it, blades must be selected with the right grit size, bond structure, and exposure. Softer bonds with finer grits reduce stress at the cut edge, resulting in cleaner separation with minimal fractures. Correct spindle speeds, feed rates, and coolant also play a major role. Applications that require tight edge integrity, such as thin silicon wafers, benefit most from blades designed specifically to reduce chipping.

Finally, cost per part ties all these factors together. A blade with a lower purchase price but poor life or inconsistent results will drive up total cost due to rework, material loss, and downtime. On the other hand, a blade optimized for the application may cost more initially but deliver longer life, higher yield, and less scrap, reducing the effective cost per part. Productivity must be considered alongside quality, since the balance between throughput and blade longevity is often what determines the most economical choice.

In practice, selecting a dicing blade requires defining which outcome is most critical to your process. Whether your priority is maximum yield, flawless edge integrity, or cost efficiency, the correct combination of blade bond, grit size, thickness, and exposure will determine the results.

Dicing Process

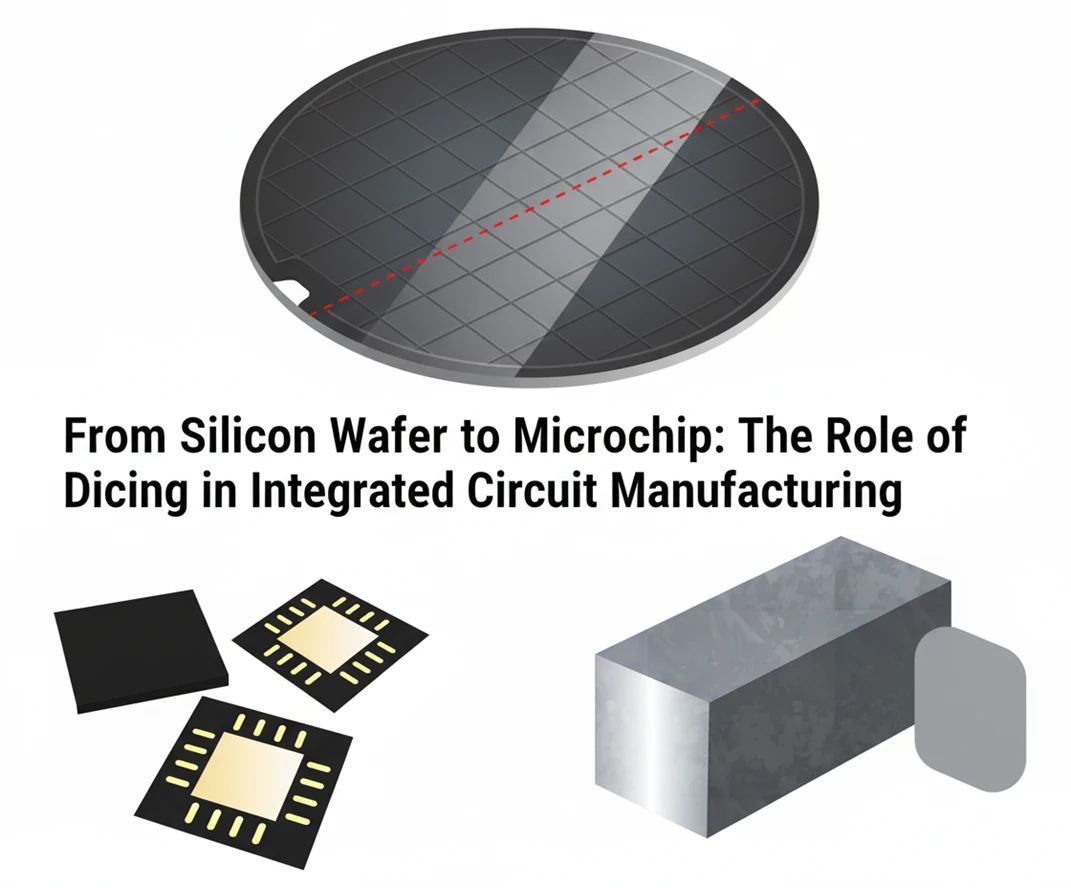

The dicing process is a precision cutting method used across a wide range of industries, from semiconductors and electronics to optics, ceramics, composites, and advanced materials. At its core, dicing involves the use of diamond dicing blades to separate, shape, or size materials with high accuracy and minimal damage. Depending on the application, the process can be performed as either full cut singulation or scribing, each offering distinct advantages.

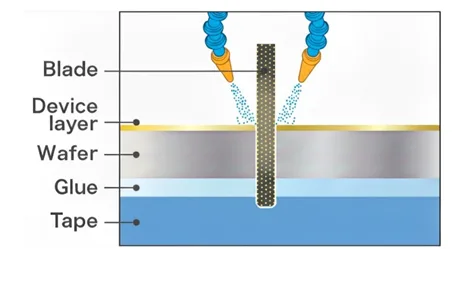

In the semiconductor industry, dicing is most commonly used for singulation, where wafers are cut into individual dies or packages. Here, the diamond blade cuts completely through the wafer until it reaches the mounting medium, such as dicing tape. This ensures clean separation of components while maintaining precise dimensions. Accuracy is critical at this stage, as even the smallest deviation can affect device performance, yield, and downstream assembly.

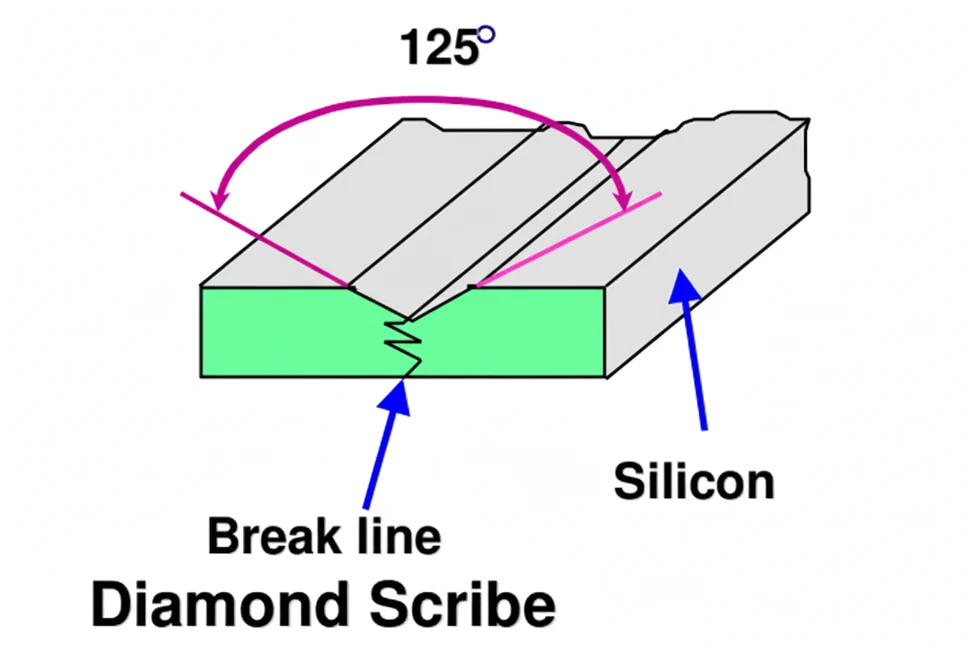

Scribing is another form of dicing where the blade only cuts partially into the material, creating a controlled line of weakness. The final separation is achieved by applying mechanical force to break the material along the scribed line. While singulation provides complete and immediate separation, scribing offers several unique benefits. It allows for higher cutting speeds, significantly reduces blade wear, and extends blade life by two to four times compared to full cut operations. Scribing is particularly effective for hard and brittle materials such as sapphire, ceramics, quartz, and specialty glasses, where controlled fracture is easier to achieve than full-depth cutting.

The choice between singulation and scribing depends on several factors, including material type, thickness, required edge quality, and production throughput. Singulation ensures nearly perfect edges and is often necessary for critical applications like semiconductors or optics where dimensional accuracy is paramount. Scribing, on the other hand, is favored where speed, reduced tool wear, and cost efficiency are more important, especially when the material naturally fractures cleanly along the scribed path.

Modern dicing processes often combine optimized blade selection, precise spindle speed, feed rate, and coolant delivery to achieve the desired balance between cut quality and productivity. Whether cutting completely through a wafer or partially scribing ceramics, the dicing process provides the flexibility and control needed to process a wide variety of materials with high yield and consistent results.

Wafer Dicing Methods and Applications

Each method has unique advantages for separating wafers and substrates while balancing cut quality, blade life, and throughput.

Full Cut

Full cut is the most basic dicing saw processing method. It cuts completely through the wafer until reaching the securing material, usually the dicing tape. This ensures each die or component is fully separated and held in place by the tape during and after cutting.

This process is widely used in semiconductor manufacturing for wafer singulation, electronics packaging for separating substrates, and in optics and ceramics for precise division of brittle materials. It is compatible with all dicing saws and does not require special equipment.

The main advantages are simple setup, reliable separation, versatility across many wafer materials and thicknesses, and faster throughput compared to partial or step cutting.

At the same time, there are important factors to manage. Chipping and edge quality can be compromised if parameters are incorrect, so blade grit size, bond type, and feed speed must be carefully chosen. Blade wear is higher because the blade fully penetrates the wafer and tape, making regular dressing and coolant use necessary. Kerf thickness selection directly affects material loss and die yield, and the adhesive strength of the dicing tape must be balanced to hold securely without causing contamination or damage.

All production-level dicing saws are capable of performing full cuts. Achieving the desired cut quality requires adjusting RPM, feed rate, coolant flow, and blade type to match the properties of the material being cut.

Partial Cut

Partial Cut is a method where the blade does not cut all the way through the wafer. Instead, it cuts only to a controlled depth, leaving part of the material and the securing tape uncut. This technique is often used when the wafer is very thin or fragile, or when a second process such as breaking or laser separation will be used to complete the singulation. By not fully penetrating the wafer, mechanical stress on the material is reduced and chipping can be minimized.

The process is common in advanced semiconductor packaging, MEMS production, and for materials that are highly brittle or expensive. It allows for greater control over cut depth and better protection of the tape from blade wear, which helps extend tool life. However, it requires precise control of blade height, spindle accuracy, and machine calibration. If the cut depth is inconsistent, die quality and yield can be affected. Coolant delivery, blade grit, and feed speed must be adjusted carefully to achieve uniform results.

Half cut is a processing method that creates grooving by cutting up to the middle of the workpiece.

It is possible to produce comb- and needle point-shapes by continuously performing the grooving process. In semiconductor manufacturing, half cutting is used in the DBG process, which is a process where grooves are first created through half cutting, and then thinning and die separation are performed at the same time by grinding.

This process is possible with all dicing saws.

Dual Cut

Dual Cut is a dicing method where the wafer is separated in two stages using different blades or cutting depths. Instead of relying on a single pass to achieve the final cut, the process begins with a first cut that removes most of the material or defines a shallow groove, followed by a second cut that completes the separation. This staged approach is used when the wafer is too thick, too hard, or too delicate to be cut effectively in a single pass.

The primary benefit of dual cutting is that it reduces mechanical stress and cutting resistance. By removing part of the material in the first cut, the second cut is smoother, with less force applied to the wafer and blade. This improves die strength and minimizes chipping, cracking, or breakage, especially in materials such as sapphire, silicon carbide, alumina ceramics, and composite substrates.

Dual cut is also applied when different blade types are needed for different stages. For example, a coarse grit blade may be used in the first cut to remove bulk material quickly, while a fine grit blade follows to produce a clean, high-quality edge. In some semiconductor and packaging applications, the first cut is made deeper than half the wafer thickness, and the second cut is programmed to overlap, ensuring complete separation without leaving uncut sections.

The process requires precise machine setup and alignment to ensure both cuts follow the exact same path. Misalignment between the first and second cut can lead to poor edge quality, dimensional inaccuracy, or die loss. Proper choice of blade grit size, bond type, concentration, spindle speed, and feed rate for each stage is essential.

Modern dicing saws can perform dual cut with programmed control, allowing manufacturers to fine-tune each stage for maximum yield. Although slower than a single full cut, this method offers higher reliability, longer blade life, and superior cut quality for demanding materials and high-value semiconductor wafers.

Step Cut

Step Cut is a more advanced process where the wafer is cut in multiple passes, often starting with a shallow cut and then making one or more deeper cuts until the wafer is fully separated. This staged approach is especially valuable for thick wafers, hard ceramics, and materials prone to chipping. By gradually increasing the cut depth, stress on the workpiece is reduced, and the blade maintains stability throughout the process.

This method improves overall cut quality, reduces front and backside chipping, and helps maintain tighter dimensional tolerances. It is often applied to silicon carbide, sapphire, alumina, and composite substrates. Step cutting is slower than full cutting but offers higher precision and lower risk of breakage. Choosing the correct sequence of depths, feed rates, and spindle speeds is critical to maintaining consistent performance and extending blade life.

All production dicing saws can perform partial and step cuts, but these methods require more precise setup, monitoring, and process optimization compared to full cut. When properly controlled, they provide significant advantages for delicate, high-value, or ultra-hard materials where cut quality and yield are more important than cutting speed.

Step cut is a processing method that performs full cutting and half cutting in two phases using a dual dicing saw, which has two spindle axes.

In semiconductor manufacturing, a wiring layer is formed on the wafer surface. Thus, the wafer is processed in two phases using a blade optimized for cutting the wiring layer, and a blade optimized for the remaining silicon single crystal, resulting in high-quality processing.

Bevel Cut

Bevel Cut is a specialized dicing process where the blade cuts the wafer at an angle rather than vertically through the material. Instead of producing a straight edge, the result is a sloped or beveled sidewall. This technique is used when reducing edge stress, improving strength, or preparing the die for advanced packaging processes.

Bevel cuts are common in power semiconductor devices, RF components, and applications where chips undergo further handling, wire bonding, or encapsulation. By removing sharp vertical edges, the risk of cracks and mechanical failure during downstream assembly is reduced. The angled edge also improves adhesion for coatings, molding compounds, or sealing materials.

Executing bevel cuts requires specialized bevel dicing blades with a profile designed for angled cutting. These blades differ from standard dicing blades because their edge geometry must produce a controlled slope without damaging the wafer surface. Process setup is more complex, as blade angle, depth of cut, feed rate, and spindle speed must all be aligned precisely to achieve uniform bevels across the wafer.

The advantages of bevel cutting include stronger die edges, reduced chipping, improved device reliability, and better compatibility with packaging steps. However, it is a slower process compared to standard full cut, and the blades wear faster due to the more demanding cutting geometry.

Modern high-precision dicing saws are capable of bevel cutting when equipped with the correct blade type and setup. Careful process control and monitoring are critical to achieve consistent bevel angles and to prevent overcutting or uneven sidewalls.

Chopper Cut

Chopper Cut is a dicing method designed for applications where only specific sections of the wafer need to be separated rather than making continuous cuts across the entire surface. Instead of cutting straight lines from one edge of the wafer to the other, the blade makes short, segmented cuts in defined areas. This method is often used in applications such as package singulation, MEMS devices, and substrates where components are arranged irregularly or where only part of the wafer needs to be processed.

The main advantage of chopper cutting is that it reduces overall cutting time and minimizes unnecessary blade wear, since the saw only cuts where separation is required. It also lowers mechanical stress on the wafer by avoiding continuous penetration across the full diameter. This makes it a valuable technique for fragile, high-value, or non-uniform materials.

The process requires precise machine programming because cut positions must be aligned with the device layout. Proper optimization of feed speed, spindle speed, and blade selection is critical to avoid excessive chipping or misalignment. Specialized chopper dicing blades are often recommended, as they must handle frequent start-and-stop contact with the material while maintaining cut stability.

Chopper cutting is compatible with advanced production dicing saws capable of step-and-repeat positioning or programmed indexing. When correctly applied, it provides faster throughput, improved tool life, and reduced material loss, especially in cases where traditional full cut or step cut would involve unnecessary cutting across non-device regions.

Chopper Traverse

Chopper Traverse is a dicing method where the saw blade makes repeated, short plunges into the wafer along a programmed path instead of cutting continuously across the entire surface in a single pass. Each plunge penetrates fully through the wafer and into the dicing tape, and the blade then retracts and indexes forward to the next cutting position. By repeating this sequence, the saw separates the wafer in controlled increments until the full line is completed.

This approach is valuable when working with very hard, thick, or fragile materials that would suffer from excessive stress during a continuous full cut. Because the blade enters and exits the material in shorter intervals, mechanical load is reduced, heat generation is lower, and the risk of wafer breakage or excessive chipping is minimized. It also provides better control over blade wear, since cutting force is distributed across multiple short plunges rather than a single long engagement.

Chopper traverse is often applied in semiconductor wafers with greater thickness, advanced ceramics, sapphire, quartz, and substrates where cut stability is critical. It is also useful for improving die strength and edge quality in applications that demand high reliability during packaging or downstream processing.

The process requires precise programming of plunge depth, step length, and feed rate. Cutting speed is generally slower compared to a standard full cut, but the trade-off is higher accuracy, better quality edges, and reduced tool failure. Coolant delivery and blade selection must be optimized to maintain consistent performance, since the blade repeatedly enters and exits the wafer.

Modern dicing saws with advanced motion control are well-suited for chopper traverse cutting. When properly set up, this method can achieve superior cut quality, longer blade life, and reduced wafer loss, especially in demanding materials and high-value semiconductor production.

Comparison table of dicing methods

|

Method |

Description |

Applications |

Advantages |

Considerations |

|---|---|---|---|---|

|

Full Cut |

Cuts completely through the wafer into the dicing tape, fully separating each die. |

Wafer singulation in semiconductors, electronics packaging, optics, ceramics. |

Simple setup, compatible with all dicing saws, reliable separation, versatile, faster throughput. |

Higher blade wear, potential chipping if parameters are incorrect, kerf width affects yield, requires proper tape adhesion. |

|

Partial Cut |

Cuts to a controlled depth without reaching the tape, leaving part of the wafer intact. |

Advanced packaging, MEMS, brittle or thin wafers, expensive substrates. |

Reduces stress, minimizes chipping, protects tape, extends blade life. |

Requires precise depth control, calibration, and coolant optimization; inconsistent depth reduces yield. |

|

Half Cut |

Cuts only halfway into the wafer to create grooves. Often used as part of the DBG process. |

Wafer thinning and die separation, groove formation for comb or needle shapes. |

Enables combined grinding and separation, supports advanced packaging processes. |

Limited to certain applications; requires precise depth alignment. |

|

Dual Cut |

Two-stage cutting: initial groove or bulk removal followed by a finishing cut. |

Thick, hard, or delicate wafers; sapphire, SiC, alumina, composites. |

Reduces cutting stress, minimizes chipping, allows different blades for each stage, improves die strength. |

Slower than full cut, requires alignment precision, misalignment risks poor quality. |

|

Step Cut |

Multi-pass cutting with increasing depths until full separation. |

Thick wafers, hard ceramics, silicon carbide, sapphire, composites. |

Higher precision, reduced chipping, tighter dimensional control, lower breakage risk. |

Slower throughput, requires careful sequencing of depth, feed, and spindle speed. |

|

Bevel Cut |

Cuts wafer at an angle to create beveled edges instead of vertical walls. |

Power semiconductors, RF devices, components requiring wire bonding or encapsulation. |

Stronger die edges, reduced cracks, improved packaging compatibility. |

Requires special bevel blades, slower process, faster blade wear, complex setup. |

|

Chopper Cut |

Segmented cuts in specific areas rather than full wafer lines. |

Package singulation, MEMS, irregular layouts, partial wafer separation. |

Reduces cutting time, lowers blade wear, minimizes stress, efficient for selective cuts. |

Requires precise programming, higher risk of misalignment, needs specialized chopper blades. |

|

Chopper Traverse |

Repeated short plunges along a cut path instead of continuous cutting. |

Thick, hard, or fragile wafers; advanced ceramics, sapphire, quartz. |

Reduces stress and heat, improves die strength, better edge quality, controls blade wear. |

Slower than continuous cuts, requires precise programming of depth and step length, higher setup complexity. |

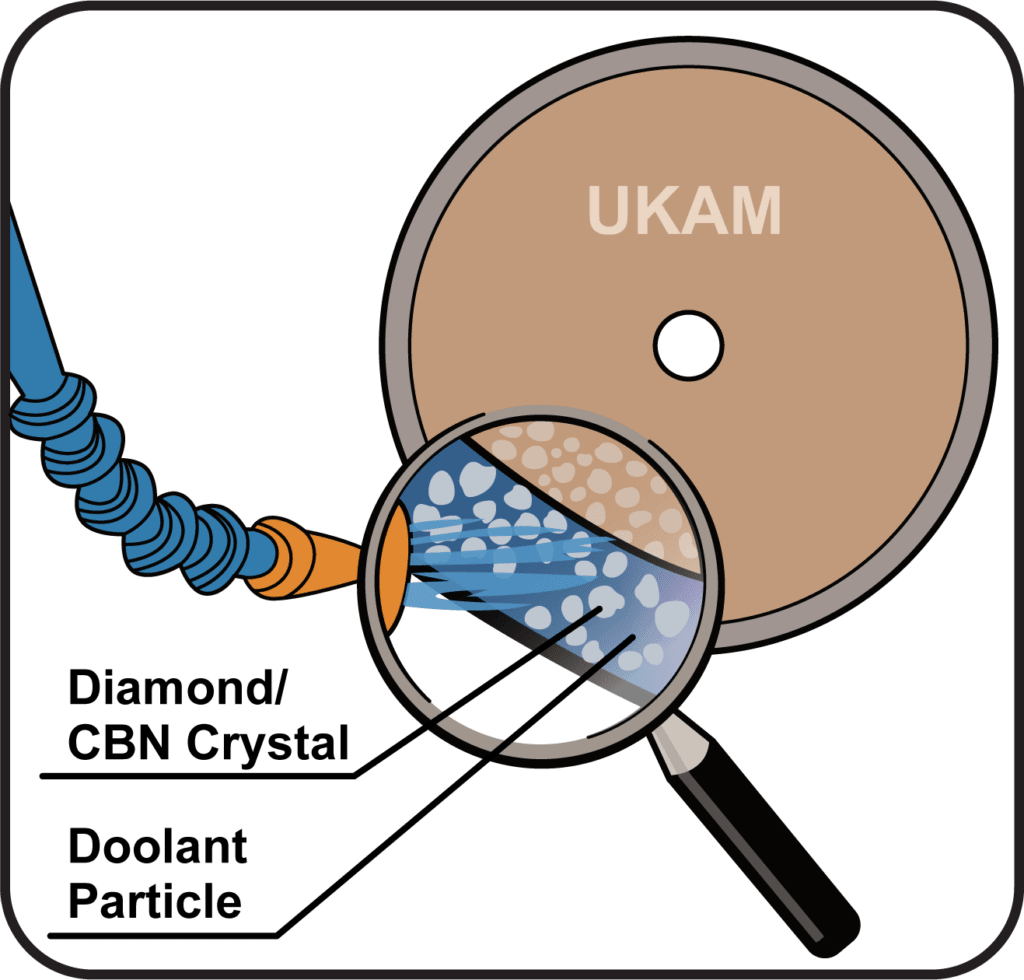

What is Dicing Blade

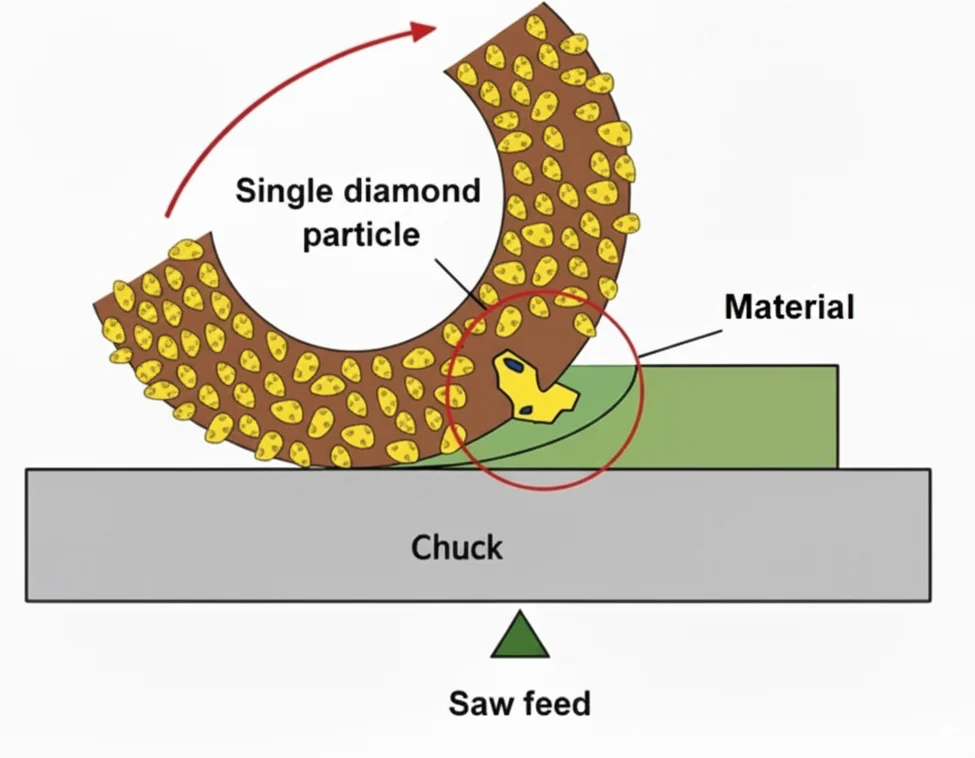

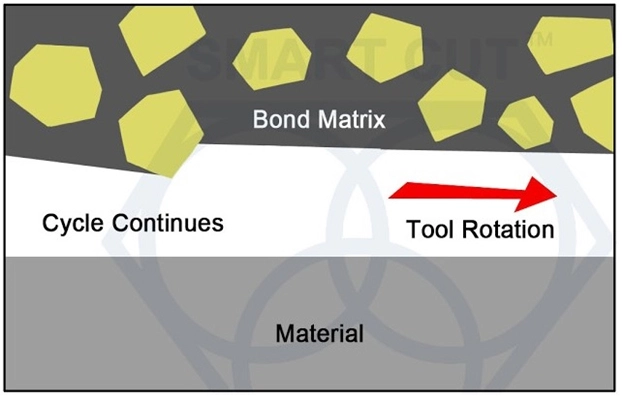

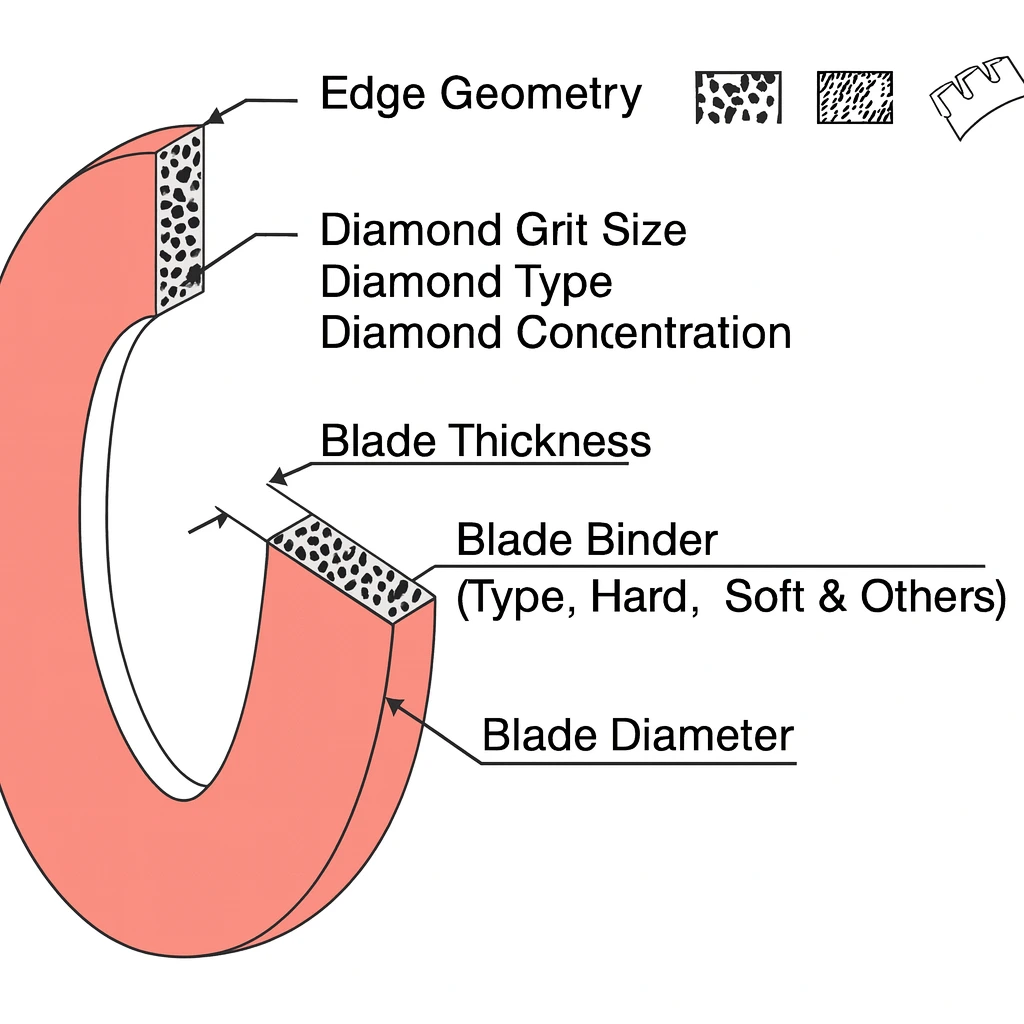

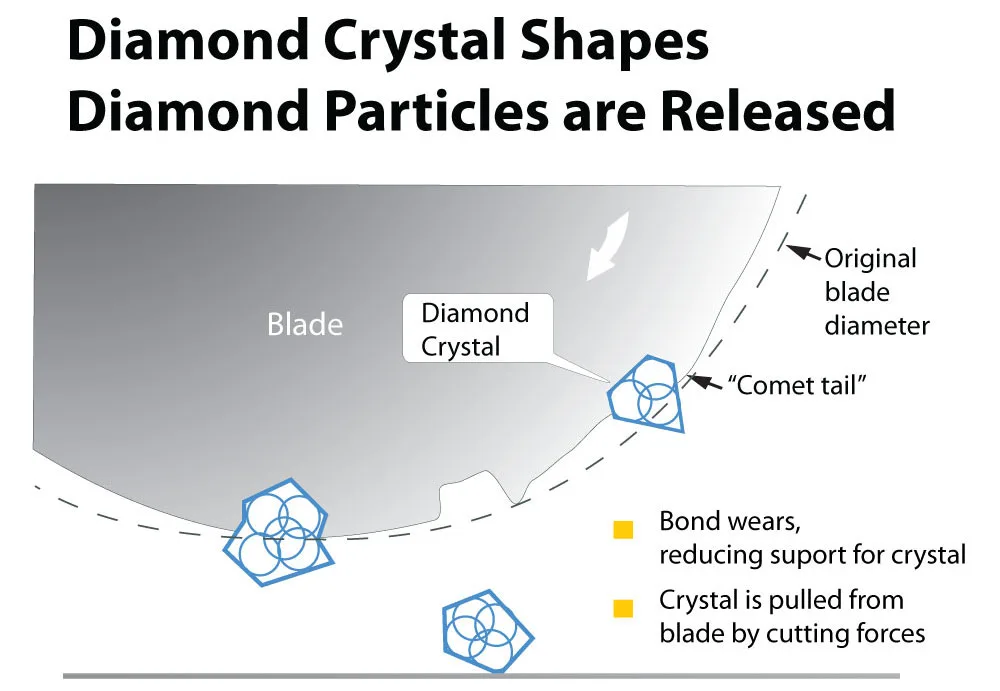

A diamond dicing blade is a precision tool with exposed diamond particles that act as small cutting edges. These particles are held in place by a bond matrix, which may be resin bond, sintered metal bond, or nickel bond in electroplated blades. The concentration of diamonds in the bond determines how many cutting edges are available, while the bond type controls how well those particles are held and released during cutting.

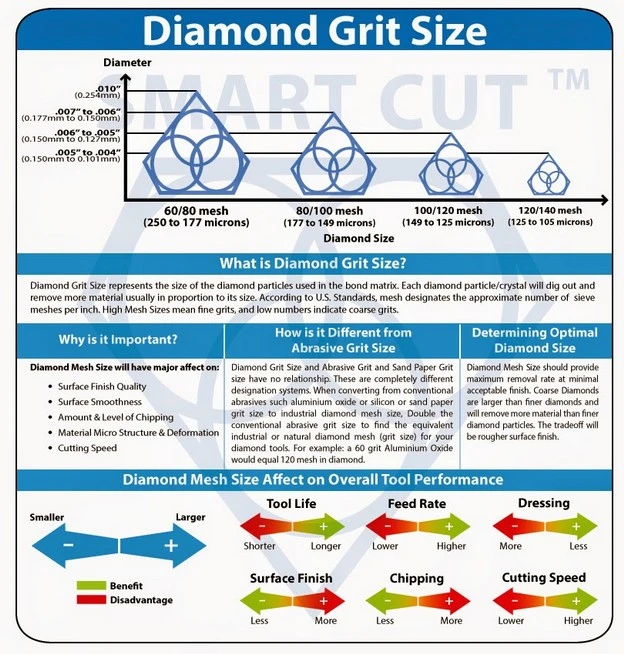

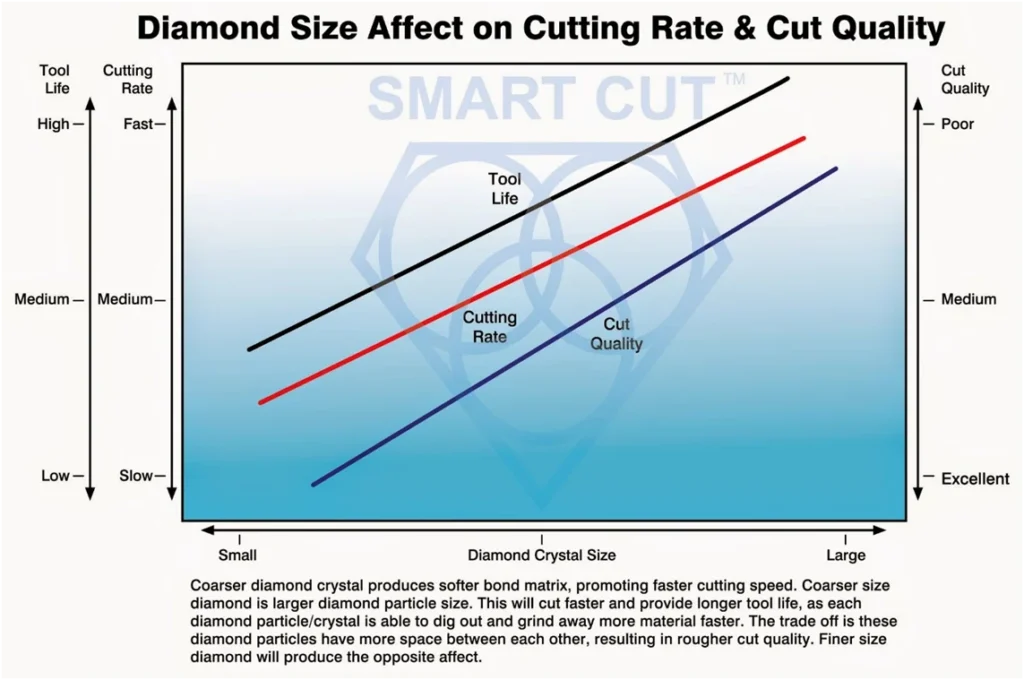

The diamond grit size directly influences the cut quality. Finer grits produce smoother surfaces with less chipping, while larger grits cut faster but leave a rougher finish. The blade thickness, which includes both the diamond particles and the bond, sets the kerf width or width of the cut. Thinner blades reduce material waste, which is important for high-value or delicate substrates.

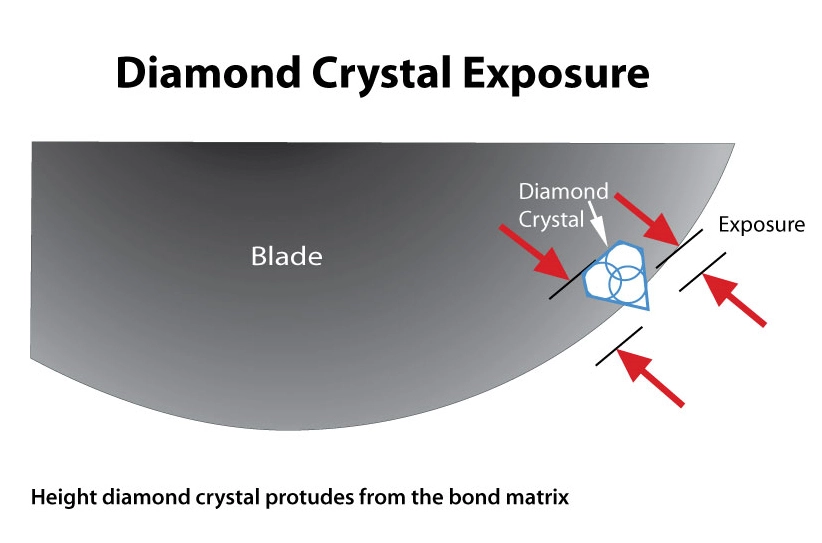

During operation, each diamond particle removes material on a microscopic level. As particles wear down, fracture, or shatter, new sharp points are exposed, allowing the blade to continue cutting. The bond system is critical in this process, because it must retain diamonds long enough to cut efficiently while also releasing them at the right time to expose fresh edges.

The final performance of the blade depends not only on its construction but also on operating conditions such as feed rate, spindle speed, depth of cut, and coolant. Matching the correct blade specifications with these parameters ensures cleaner cuts, longer blade life, and consistent results. Ultimately, blade success relies on the bond’s ability to balance diamond retention with timely release, keeping sharp cutting edges available throughout the process.

Why Use Diamond

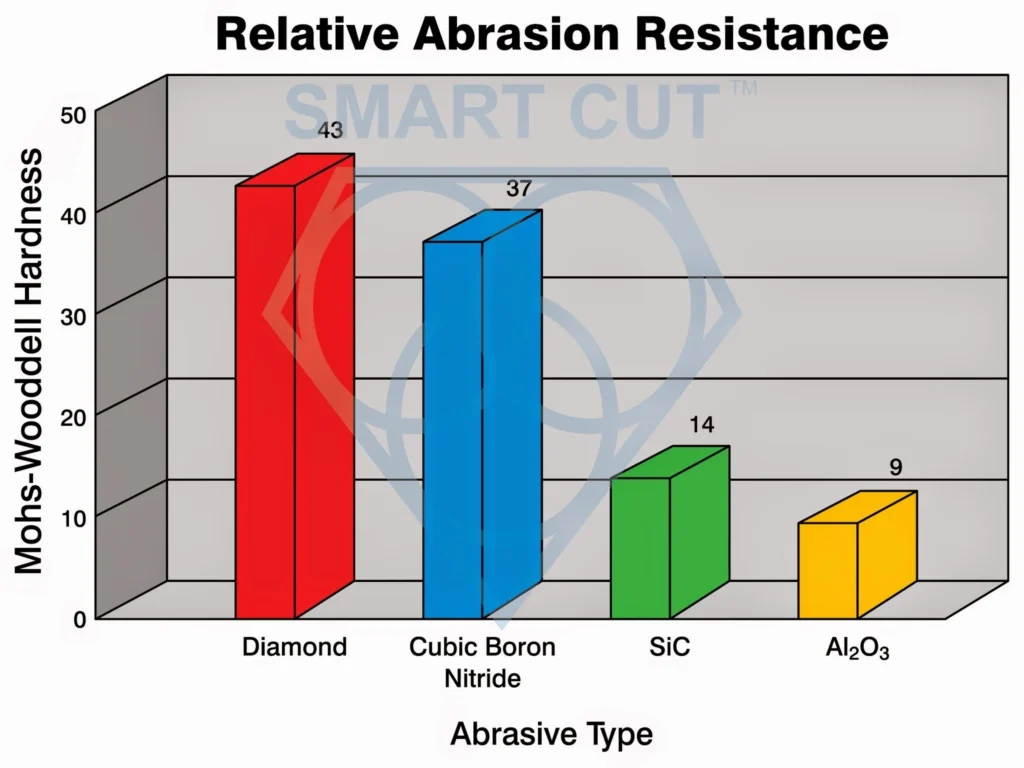

Diamond is the hardest material known to mankind, making it the most effective abrasive for precision cutting applications. When incorporated into dicing blades, diamond particles grind material at the micro and even nano level, enabling unmatched accuracy and control. Because of its extreme hardness, diamond can machine materials with hardness values of 40 Rockwell C and higher, including many advanced ceramics, composites, crystals, and superhard metals that conventional abrasives, carbide, or high-speed steel cannot cut effectively.

Diamond blades cut faster, generate smoother surface finishes, and provide more consistent results across a wide range of applications. This means improved yield, lower cost per part, and reduced downtime due to tool changes. Diamond’s hardness, natural strength, and wear resistance remain far superior to all conventional abrasives, ensuring a longer tool life and better process reliability.

CBN (Cubic Boron Nitride) is the second hardest material after diamond and offers unique benefits in specific applications. Unlike diamond, CBN does not chemically react with iron-based alloys at high temperatures, which makes it ideal for cutting hardened steels, superalloys, and ferrous materials. CBN blades deliver excellent dimensional accuracy, longer tool life, and stable performance in environments where diamond is not suitable.

Together, diamond and CBN cover the full spectrum of hard-to-machine materials, making them the preferred choice for industries such as electronics, aerospace, optics, and advanced materials research where precision and reliability are critical.

Dicing Blade Types: Hubbed vs Hubbless

Dicing blades are available in two main types: hubbed and hubless. A hubbed diamond dicing blade is permanently mounted on a precision aluminum hub and comes ready to use. Once the blade reaches the end of its life, the entire assembly is disposed of. These blades are typically chosen for applications that demand minimal vibration and high stability, such as cutting silicon and germanium wafers. Because the hub adds stiffness, hubbed blades produce a straighter kerf, cleaner cuts, and less chipping, while also requiring minimal dressing. They are easier for operators to handle and install, making them ideal for high-volume production where consistency is critical.

Hubless diamond dicing blades, by contrast, are mounted on reusable flange assemblies. The same flanges can be used repeatedly with different blades. These blades are widely applied in situations where cooling efficiency is critical, since advanced flange designs allow coolant to reach the blade directly, improving both cut quality and blade life. Hubless blades also provide flexibility, giving operators the ability to experiment with different flange configurations to fine-tune performance for specific materials. However, they require more careful handling. Foreign particles, slurry buildup, and improper cleaning of the inner and outer flanges can significantly affect cut quality. For this reason, maintaining flange cleanliness is essential to ensure consistent results.

Hubbed blades are valued for their ease of use, superior rigidity, and reduced vibration, which translate into higher precision and less chipping. They come pre-dressed and require very little setup time, making them especially efficient for delicate materials and operations where downtime must be minimized. Hubless blades, on the other hand, are advantageous because they are cost-effective in the long term, allow reuse of flanges, and can be paired with high-cooling flange systems for demanding applications. This makes them well-suited for advanced wafer cutting and other processes where extended blade life and thermal control are important.

comparison table between Hubbed and Hubless Diamond Dicing Blades

|

Feature |

Hubbed Diamond Dicing Blades |

Hubless Diamond Dicing Blades |

|---|---|---|

|

Mounting |

Permanently mounted on a precision aluminum hub, disposed of after use |

Mounted on reusable flange assemblies, flanges can be reused with new blades |

|

Ease of Handling |

Easier to handle and install, minimal setup time |

Requires careful mounting and alignment on flanges |

|

Blade Stiffness |

Very stiff due to aluminum hub, reducing vibration |

Less rigid, stiffness depends on flange assembly |

|

Cut Quality |

Produces straighter kerf, cleaner cuts, and less chipping |

Good quality but more sensitive to setup and cleanliness |

|

Vibration Control |

Minimal vibration, excellent stability |

More prone to vibration if flanges are not clean or aligned |

|

Dressing |

Pre-dressed, requires very little or no dressing |

Requires more careful dressing depending on application |

|

Cooling Efficiency |

Limited coolant flow to the blade |

High-cooling flange options allow direct coolant flow for better thermal control |

|

Sensitivity to Contamination |

Less sensitive to slurry or foreign particles |

More sensitive, requires thorough cleaning of inner and outer flanges |

|

Flexibility |

Fixed configuration, no flange changes possible |

Allows use of different flange types to optimize performance |

|

Applications |

Best for silicon and germanium wafers, delicate materials, and high-precision work |

Preferred when cooling is critical (advanced wafer cutting, ceramics, composites) |

|

Cost Effectiveness |

Higher cost per blade since hub cannot be reused |

More cost-effective long term due to reusable flanges |

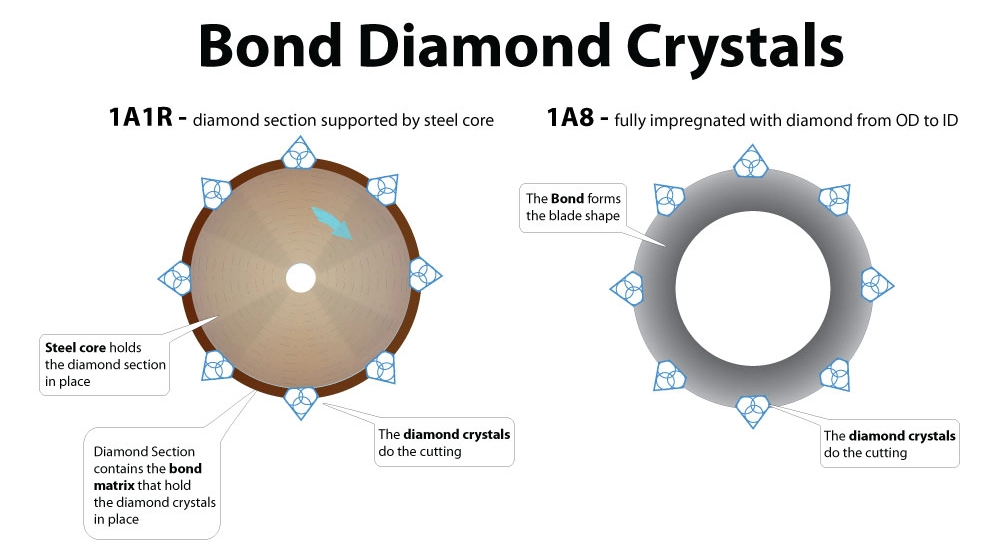

Fully Impregnated Dicing Blades vs Steel Core

When selecting dicing blades, one of the important distinctions to understand is between blades fully impregnated with diamond and blades that use a steel core with a diamond section bonded to the outside rim. Both designs have advantages depending on your material, equipment, and production requirements.

Fully impregnated diamond blades are manufactured so that the cutting edge is entirely composed of diamond and bonding material. There is no steel core under the diamond section. This construction allows the blade to be extremely thin and precise, making it ideal for applications where minimum kerf, reduced material loss, and maximum yield are critical. Because the entire blade thickness is diamond, wear is more uniform, and the blade can maintain consistent performance over its usable life. These blades are commonly chosen for semiconductors, MEMS, and very thin or fragile substrates where precision outweighs durability. The trade-off is that they tend to be less rigid and can wear faster, especially in tougher materials.

Steel core dicing blades are built with a metal core that provides structural support, while the diamond section is bonded around the edge. The steel core increases blade stability, reduces vibration, and improves resistance to side deflection. This makes them more durable and suitable for thicker wafers, ceramics, sapphire, and harder materials where cutting forces are higher. Steel core blades typically offer longer blade life and higher feed rate capability. However, because the core limits how thin the diamond section can be, these blades often have wider kerfs compared to fully impregnated blades, which means more material loss.

The choice between the two comes down to process requirements. If your application demands the thinnest kerf and highest possible precision, fully impregnated blades are the better option. If you require greater stability, longer life, and the ability to cut harder or thicker materials at higher throughput, a steel core blade is the more reliable choice. Many production environments use both types depending on whether the priority is yield and precision or durability and productivity.

|

Feature |

Fully Impregnated Diamond Dicing Blades |

Steel Core Dicing Blades |

|---|---|---|

|

Construction |

Entire blade thickness is diamond and bond material |

Steel or alloy core with diamond rim bonded to the outside edge |

|

Kerf Width |

Ultra-thin kerfs possible for maximum yield and minimal material loss |

Thicker kerfs due to steel support, more material waste |

|

Precision |

Highest precision and dimensional accuracy, best for semiconductors and MEMS |

Good precision, but limited by core thickness and rigidity |

|

Stability |

Less rigid, can deflect under high loads |

Very stable due to steel core, reduced vibration and run-out |

|

Blade Life |

Shorter life, wears faster in harder materials |

Longer blade life, can handle tougher and thicker substrates |

|

Material Suitability |

Thin wafers, MEMS, delicate substrates, optical materials |

Thicker wafers, ceramics, sapphire, alumina, harder materials |

|

Feed Rates |

Requires lower feed rates for stability |

Can handle higher feed rates without compromising quality |

|

Cost per Part |

Can reduce cost when maximum yield is critical (due to minimal kerf loss) |

Reduces cost when throughput and durability are more important |

Dicing Blade Bond Types:

Dicing Blade Bond Table of Comparison

|

DICING BLADE BOND TYPES |

RESIN |

SINTERED (METAL BOND) |

HYBRID BONDTM |

NICKEL BOND (HUBLESS) |

NICKEL BOND (HUBBED) |

|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

DICING BLADE APPLICATIONS |

|

|

|

|

|

|

Dicing Blade Characteristics |

Resin Bond dicing blade are typically more forgiving. self dressing, and freer cutting. Excellent choice for Ultra Hard & Brittle Materials. Recommended for applications where cut quality and surface finish is very important. |

Sintered (metal bond) Dicing blades have excellent form holding & corner characteristics, provide very long life, high level of consistency. Recommended for users requiring very straight cuts and larger blade |

You will find all the advantages of cutting speed and fine finish that you have come to expect in a resin bond, and long life, consistency, aggressiveness, durability, and excellent performance on you look for in a metal bond. |

Nickel Bond dicing blades are available with and without hubs. Capable of maintaining excellent form & sharpness. Widely used for cutting wafers and thin substrates. Nickel Bond dicing blades provide minimum level of chipping on wide variety materials. |

Nickel Bond Hubbed dicing blades are typically used for dicing silicon and III-V materials. Creates very thin kerfs, <50 microns. Providing excellent cut quality with low wear rate |

|

DICING BLADE BONDS |

|

|

|

|

|

|

Abrasive (Diamond/CBN) Sizes |

3 to 151 micron |

3 to 126 micron |

3 to 151 micron |

3 to 70 micron |

2 to 50 micron |

|

Abrasive (Diamond/CBN) Types |

Coated & Uncoated Synthetic Diamond or CBN |

Natural Diamond, Coated & |

Coated & Uncoated Synthetic Diamond or CBN |

Natural & Synthetic Diamond |

Natural & Synthetic Diamond |

|

Abrasive Concentration |

25 to 200 con |

25 to 200 con |

25 to 200 con |

100 to 250 con |

100 to 250 con |

|

Minimum Dicing Blade Thickness |

.003" (.076mm) |

.004" (0.101mm) |

.004" (0.101mm) |

0003" (0.0076mm) |

.0003" (0.0076mm) |

NEW GENERATION AND TECHNOLOGY

SINTERED (METAL BOND)

SMART CUT® Series (SCM)

Diamond & CBN Dicing Blades

SMART CUT® Series (SCM) Sintered (Metal Bond) Diamond CBN Dicing Blades are designed to provide some the best return on investment (ROI) in dicing application. They provide superior longevity, accuracy, and consistency across a wide range of applications. Engineered using advanced SMART CUT® technology, these blades are among the thinnest, most durable, and highest-performing dicing solutions available today. Their sintered metal bond structure ensures a self-renewing sharpness, delivering consistently clean and precise cuts over extended periods.

The Metal Bond Hubless Blade formulation features a specially developed sintered metal bond matrix that securely holds and retains diamond grains, enhancing blade durability and cutting efficiency. Unlike standard formulations, these blades have lower wear resistance, helping to reduce defects such as slanted-kerf and edge chipping, ensuring high-quality, straight cuts. Their high rigidity is equal to or surpasses that of electroformed blades, preventing wavy cutting and improving processing speed, stability, and cutting consistency. This makes them particularly well-suited for applications requiring long blade exposure and ultra-precise results.

Manufactured through high-pressure sintering, these blades are composed of multiple layers of high-quality diamond particles embedded within a metal matrix consisting of iron, cobalt, nickel, bronze, copper, tungsten, and other metal alloys.

This structure ensures excellent wear resistance and cutting efficiency, making them ideal for cutting hard, brittle, and high-precision materials such as BGA, soft alumina, TiC, LTCC, ferrite, silicon wafers, glass, piezoelectric ceramics, quartz, optical materials, and semiconductor components. The controlled sintering process optimizes the balance between cutting speed, blade longevity, and wear resistance, ensuring a consistent cutting performance throughout the blade’s lifecycle.

With their high rigidity and minimal blade wear, SMART CUT® SCM Sintered (Metal Bond) Dicing Blades ensure stable, highly precise cutting with minimal material deformation and contamination. They are designed to withstand high cutting loads while maintaining edge integrity, making them an excellent choice for applications where accuracy, durability, and efficiency are critical. The self-sharpening mechanism of these blades allows for continuous diamond exposure, preventing glazing and reducing the need for frequent blade replacements.

SMART CUT® SCM dicing blades offer a wide selection of blade thicknesses, ranging from 80 µm to 1500 µm, accommodating both ultra-thin and heavy-duty cutting requirements. Additionally, they provide customizable diamond grit sizes from 2 µm to 70 µm, ensuring the optimal balance between cutting speed, material removal rate, and surface finish quality. These blades are also available with serrated edges and various edge shapes, enhancing their ability to cut specific materials with greater efficiency and precision.

By integrating advanced rigidity, self-sharpening properties, and optimized bond formulations, SMART CUT® SCM Sintered (Metal Bond) Dicing Blades deliver exceptional performance across industries including electronics, semiconductor manufacturing, ceramics, and optics. Their prolonged lifespan, superior rigidity, and optimized diamond concentration make them the preferred choice for precision cutting applications where minimizing blade change frequency, improving cut quality, and enhancing overall process efficiency are essential.

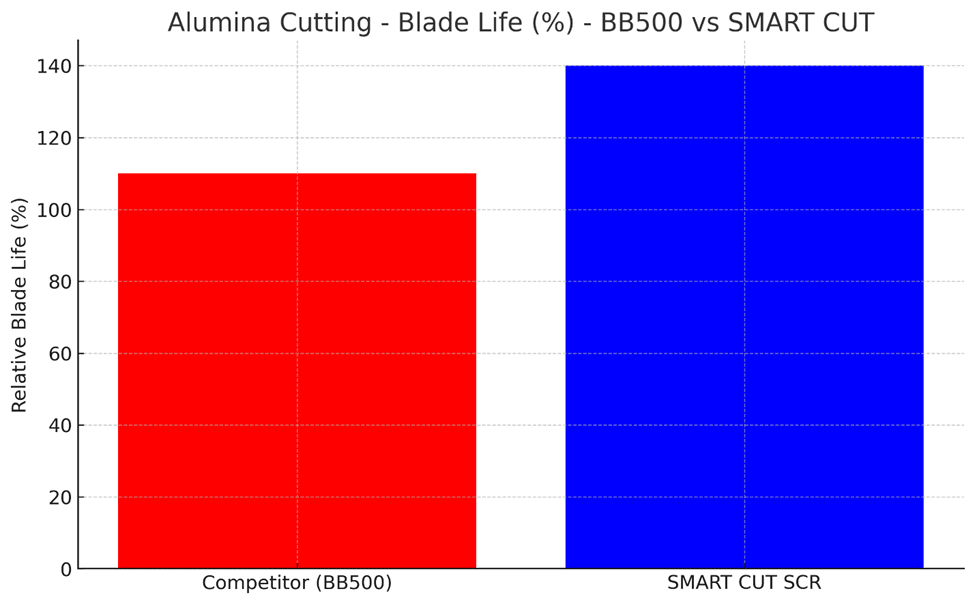

Compare to any other Sintered (Metal Bond) Dicing Blade

Application:

- Soft Alumina

- TiC

- LTCC

- Ferrite

- CSP

- Optical

- Sapphire

- Semiconductors (QFN, BGA, LGA, LED, and Diode)

- Optical Glass (Filter, Blue Glass, Beveled Glass)

- Quartz, Crystal, and Gems

- Magnetic Material

- Carbide

- Tool Steels

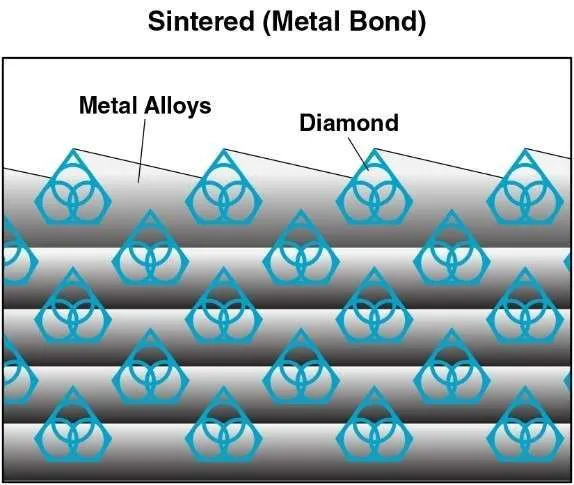

About Sintered (Metal Bond)

Sintered (Metal bonded) diamond blades diamonds sintered and multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. Metal Bonded Dicing Blades are “impregnated” with diamonds. The compacted materials are then hot pressed or sintered to full density. Heating rate, applied pressure, sintering temperature and holding time, are all controlled according to the matrix composition. This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance possible on any large variety of material. The metal bond surrounding the diamonds must wear away to continuously keep re-exposing the diamonds for the diamond tool to continue cutting.

Sintered (metal bonded) dicing blades are recommended for cutting wide variety of materials from 45 to 75 on Rockwell Scale (5 to 9.5 on mohs scale of hardness). It is more wear resistant and holds diamond well in place, usually producing the highest yield/cutting ratio.

As a general rule of thumb, Metal Bond (sintered) diamond dicing blades longer than other diamond bond blades such as resin bond and electroplated (nickel bond) blades.

They wear evenly, and are known for their long life & consistency. Metal bond matrix does not protrude diamonds very high and hence usually requires lower cutting speeds than electroplated (nickel bond) and resin bond blades. In many dicing applications sintered (metal bond) dicing blades are used in applications which are not super hard or super brittle and with minimum tendency to produce chips or cracks.

NEW GENERATION AND TECHNOLOGY

HYBRID BOND

SMART CUT® Series (SCH)

Diamond & CBN Dicing Blades

SMART CUT® HYBRID (RESIN) SCH series New Generation & Technology Dicing Blade is the highest performance dicing blade available today.

SMART CUT® SCH Series Hybrid Bond Dicing Blades are a breakthrough in dicing blade technology, combining the exceptional longevity of sintered (metal bond) blades with the superior precision, smoothness, and minimal chipping of resin bond blades. Developed in response to the need for a longer-lasting resin bond blade, this series was engineered through years of research, development, and real-world testing, resulting in a blade that delivers unparalleled performance, efficiency, and consistency.

Unlike conventional resin bond blades, which tend to wear down quickly and require frequent dressing, the SMART CUT® SCH Series is designed for extended life, lasting three to four times longer than traditional resin bond dicing blades. The hybrid bond structure provides exceptional wear resistance, maintaining its form, shape, and cutting precision throughout its lifespan. These blades excel in high-load and high-feed-rate applications while retaining their integrity and performance under demanding conditions.

The Best of Both Worlds: Longevity Precision

SMART CUT® SCH dicing blades provide the durability of metal bond blades without sacrificing the cutting quality of resin bond blades. This innovative hybrid bond formulation minimizes chipping, delivers best cut quality, and maintains tight tolerances, making it the perfect choice for applications requiring both long blade life and high cut quality.

These blades are engineered to be more universal, and are capable of handling higher loads and feed rates without degradation. The advanced diamond orientation and bond structure ensure that each diamond works at maximum efficiency, reducing unnecessary wear and optimizing cutting performance.

Unmatched Performance Features

With its self-sharpening open bond structure, the SCH Series prevents glazing, ensuring the bond renews itself naturally, minimizing dressing requirements while maintaining peak cutting efficiency. The blades feature maximum coolant absorption, allowing better heat dissipation and improved coolant retention, which prevents overheating and enhances cut quality.

The aggressive cutting action allows the SCH Series to cut faster than standard resin bond blades, yet still provides a clean, smooth finish with minimal material deformation. The superior structural integrity of the blade ensures that it maintains consistent roundness, cutting speed, and accuracy, resulting in repeatable, high-quality cuts throughout its life.

SCH Series significantly reduces blade wear, ensuring extended operation before replacement. Its robust design minimizes chipping and prevents material damage, maximizing process consistency and precision. Unlike conventional resin bond dicing blades, SMART CUT® SCH blades require minimal dressing, helping to maintain consistent cutting speed and performance while reducing downtime and operating costs.

By combining the longevity of sintered (metal bond) blades with the superior cut quality of resin bond blades, SMART CUT® SCH Series Hybrid Bond Dicing Blades set a new standard in dicing performance. These blades provide unmatched durability, efficiency, and cost savings—ensuring maximum return on investment for manufacturers seeking the best balance between blade life and cut quality.

Application

-

BGA Packages

BGA Packages

-

QFN

QFN

-

Aluminum oxide (Al₂O₃)

Aluminum oxide (Al₂O₃)

-

Silicon nitride (Si₃N₄)

Silicon nitride (Si₃N₄)

-

Silicon carbide (SiC)

Silicon carbide (SiC)

-

Sapphire Boron Carbide (B₄C)

Sapphire Boron Carbide (B₄C)

-

Alsmag

Alsmag

-

LiTaO₃ & LiNbO

LiTaO₃ & LiNbO

-

FR4 and Resin

FR4 and Resin

Features

- Excellent form & corner holding characteristics

- Best tolerances in the industry

- Superior Cut Quality

- Unmatched Consistency

- Self Sharpening Open Bond

- Requires Minimal Dressing

- Maximum cutting performance

- No glazing

- Faster cutting action

- Improved surface finish quality

- Better coolant retention

- No Material Deformation

- Lasts 3 to 4 times longer than conventional resin bond blades

RESIN BOND

SMART CUT® Series (SC®) RESIN BOND DIAMOND & CBN DICING BLADES

Maintain excellent form & sharpness. Providing lower wear rate, longer life, and minimum level of chipping on wide variety materials.

SMART CUT® Resin series New Generation & Technology Dicing Blade is the highest performance Resin Bond Dicing Blade available today! SMART CUT® Resin Dicing Blade lasts longer than any resin bond diamond dicing blade and maintains better form & shape consistently through its life. Resin Bond dicing blade are typically more forgiving, self dressing, and freer cutting. Excellent choice for Ultra Hard & Brittle Materials. Recommended for applications where cut quality and surface finish is very important.

SMART CUT® Resin series New Generation & Technology Dicing Blade are produced using phenolic resin as the binder, diamond abrasive as cutting media, ceramic & other advanced components as filler. UKAM Industrial Resin Bond Blades are manufactured with advanced molding process. available in a large variety of geometries, diamond sizes, diamond concentrations, and bond harnesses.

SMART CUT® RESIN SCR Dicing Blades are engineered to significantly outperform conventional resin bond blades in both durability and performance. Unlike standard resin blades that quickly dull and lose shape, SMART CUT® blades maintain their roundness, sharpness, and structural integrity throughout their life. They handle higher loads and feed rates, making them suitable for both low- and high-power dicing saws. Their heavy-duty construction and open bond design reduce the need for frequent dressing, minimize blade wreckage, and allow for superior coolant absorption—keeping the blade cool and stable during operation.

These blades cut faster and more aggressively while still delivering the smooth surface finish expected from a resin bond. They also resist glazing and maintain consistent cutting speed with minimal chipping. SMART CUT® RESIN SCR Blades use advanced phenolic resin formulations, higher grade tightly graded diamonds, and proprietary molding techniques—overcoming the limitations of conventional resin bonds and enabling use in a wider range of applications. With their self-renewing bond structure and longer life, they offer cleaner cuts, reduced downtime, and lower overall cost per cut—truly setting a new standard for what resin bond dicing blades can achieve.

Features:

- Highly Customizable

- Improved Precision

- Versatility in Applications

- Resistant to Wear

- Low Vibration

- High Strength and Rigidity

- Extended Blade Life

- Minimal Deflection

- Ideal for Deep or Aggressive Cutting

- Available in Various Grit Formulas

Advantages

- Maximum cutting performance

- No glazing

- Faster cutting action

- Improved surface finish quality

- Better coolant retention

- No Material Deformation

About Resin Bond

Resin bond dicing blades are made with high temperature phenolic resin, diamond particles, ceramic filler and often additional additives. Resin Bond is the softest of all the bonds, frequently used in applications that require a smooth surface. This type of dicing blade is used on majority of ultra hard & brittle materials. Resin bond dicing blades allow the bond matrix to wear faster, and allow for diamond particles/crystals to break out of their matrix faster, so that new sharp diamond particles become exposed. This self sharpening characteristic of resin bond dicing blades, based on faster bond wear out is what make this blade choice in almost half of all dicing application. Typical Resin Bond Diamond Blades last less than Sintered (Metal Bond) diamond blades, but more than electroplated (nickel bond) diamond blades. finish and minimum amount of chipping.

NEW GENERATION AND TECHNOLOGY

NICKEL BOND HUBLESS

SMART CUT® Series (SCN) DIAMOND & CBN DICING BLADES

SMART CUT® Nickel Bond Hubless Dicing Blades are designed to provide exceptional precision, longevity, and consistency for cutting a wide range of materials. Engineered with a high diamond concentration and advanced Nickel bond matrix, these blades deliver efficient cutting performance with minimal heat generation. Their ability to maintain excellent form retention and diamond exposure makes them ideal for applications requiring high accuracy, such as wafer dicing, thin substrate cutting, and microelectronics fabrication.

The Nickel binder used in these blades is specifically developed to offer a hard bond for soft materials, ensuring longer blade life and reduced wear rates. This unique combination of bond structure and abrasive composition allows for faster cutting while minimizing chipping, making it an optimal choice for materials such as printed circuit boards (PCB), silicon, and ball grid array (BGA) components. By maintaining sharp diamond exposure throughout the cutting process, these blades enhance material removal efficiency while ensuring a stable and controlled cut.

SMART CUT® Nickel Bond Hubless Blades are available in a variety of configurations to meet diverse application needs. Blade thickness ranges from 50 µm (2 mil) to 300 µm (12 mil), allowing for precise customization based on material requirements. The diamond grit size varies from 3 µm to 50 µm, providing versatility across different levels of cutting precision. Custom serration designs and various edge shapes are also available, further enhancing cutting performance for specialized applications.

These blades are engineered for superior cutting results, offering maximum performance and reliability. With excellent form and corner-holding characteristics, they maintain the industry’s best tolerances. Their advanced design minimizes chipping, ensuring a cleaner and smoother finish while significantly reducing blade wear. By extending blade life and optimizing cutting speed, these blades enhance process efficiency, reduce material loss, and lower overall operational costs. Their non-glazing properties enable a faster cutting action while improving surface finish quality, making them a preferred choice for high-precision applications. Additionally, superior coolant retention improves thermal management, preventing material deformation and ensuring a stable cutting process.

SMART CUT® Nickel Bond Hubless Dicing Blades set the standard for precision cutting across industries that require accuracy, efficiency, and consistency. With their ability to maintain sharpness, reduce process variability, and deliver high-quality results, they provide an ideal solution for advanced material processing. Contact us today for more information or to request a quote and discover how SMART CUT® dicing blades can optimize your cutting operations.

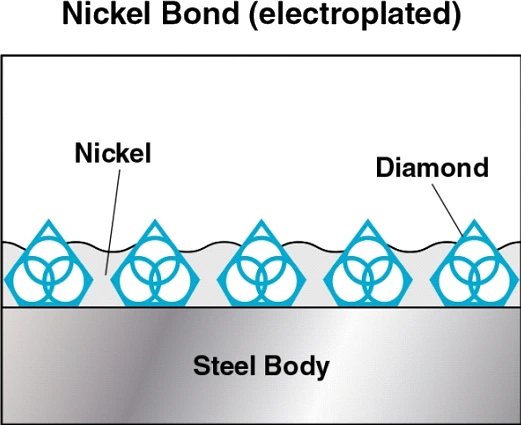

About Nickel (Plated) Bond

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough, durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process, electroplated diamonds are able to retain their original shape and dimensions throughout their working life. Unlike sintered) metal bond or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside. Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

Features

- Excellent form & corner holding characteristics

- Best tolerances in the industry

- Superior Cut Quality

- Unmatched Consistency

- Universal Application

- Requires Minimal Dressing

Benefits

- Increases Blade Life

- Reduce Chipping

- Reduce Blade Wear

- Increase Process Consistency

- Maintain Consistent Cutting Speed

- Minimum Loss of Material

- Reduce Cost

Advantages

- Maximum cutting performance

- No glazing

- Faster cutting action

- Improved surface finish quality

- Better coolant retention

- No Material Deformation

- Faster Cutting Speed

NEW GENERATION AND TECHNOLOGY

Nickel Bond Hubbed Dicing Blades

SMART CUT® Series SCNH

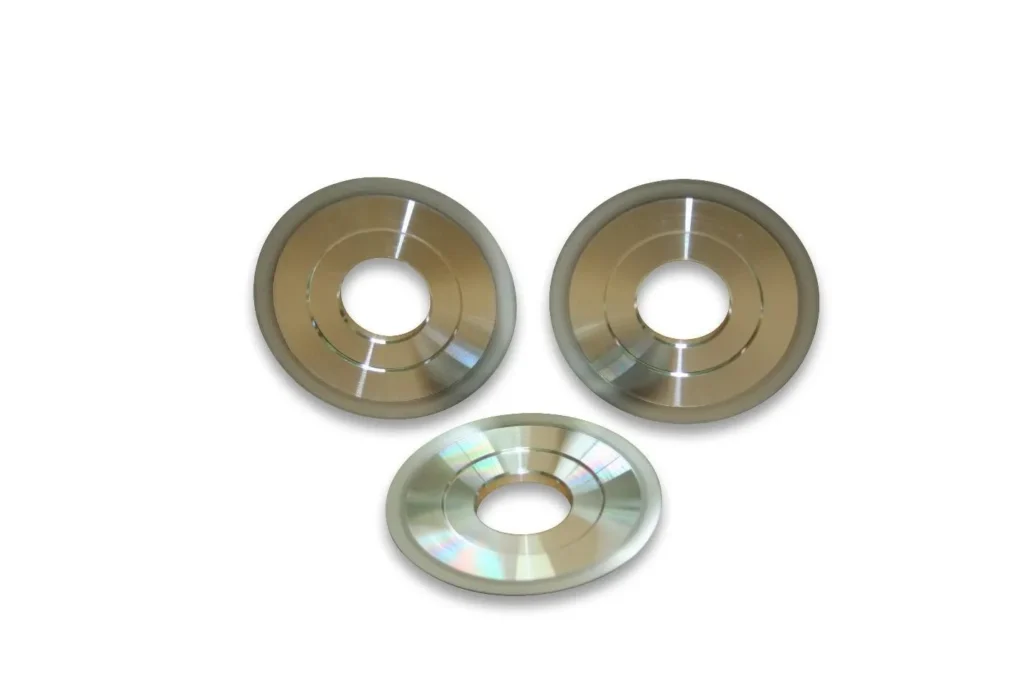

SMART CUT® Nickel Bond Hubbed Dicing Blades are the preferred choice for semiconductor component manufacturing, offering ultra-thin precision cutting with exceptional stability. Designed for dicing narrow wafers with impeccable accuracy, these blades utilize a nickel electroplated bond combined with larger diamond grit, ensuring an extended lifespan and consistently high-quality performance.

Engineered for maximum customization, SMART CUT® Nickel Bond Hubbed Dicing Blades are available in a wide range of stocked variations.

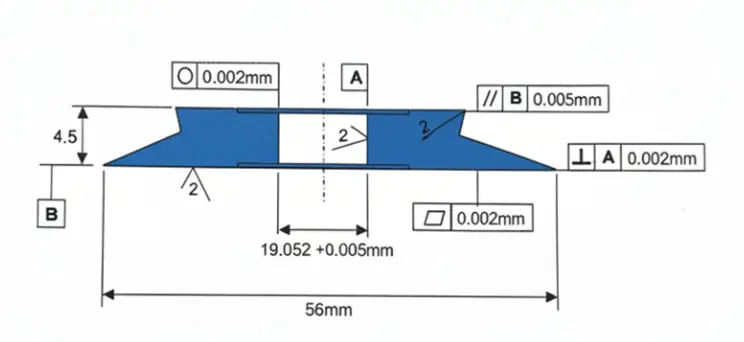

Each blade consists of a precisely manufactured hub, designed for optimum cooling efficiency, and carries an electrodeposited nickel alloy layer embedded with diamond grains. The etched aluminum support is removed during manufacturing, leaving a free-standing nickel-diamond matrix that determines cut depth based on the exposed diamond rim.

UKAM Industrial Superhard Tools’ proprietary manufacturing process ensures precise control over diamond grit size, concentration, and nickel bond hardness, optimizing these variables to produce hubbed dicing blades that offer unmatched cut quality, superior blade life, and high throughput efficiency. These blades are highly versatile and perform exceptionally well in a wide range of applications, including silicon wafer dicing, brittle III-V compound materials such as gallium arsenide and indium phosphide, PZT ceramics, tantalates, aluminas, and silica-filled plastics for chip-scale package singulation.

SMART CUT® Nickel Bond Hubbed Dicing Blades feature a robust structure that enhances durability and provides superior cut quality with minimal chipping. They create ultra-thin kerfs, often less than 50 microns, enabling precision cutting while maintaining tight kerf width control. Their improved diamond exposure reduces the need for frequent dressing, allowing for more efficient and consistent cutting performance. These blades are designed to handle high exposure-to-width ratios and support advanced dicing techniques such as bevel and step cutting. A wide range of grit sizes and bond types is available to accommodate different application requirements.

This results in excellent cut quality with a low wear rate, reducing waste and improving productivity. The combination of an ultra-thin diamond blade and a precision aluminum hub provides stable cutting results while improving overall operation efficiency. These blades are particularly well suited for dicing silicon and III-V semiconductor materials.

Features:

- Ultra-thin precision cutting for semiconductor applications

- Nickel electroplated bond with larger diamond grit for longer blade life

- Customizable options

- Optimized hub design for superior cooling efficiency

- Free-standing nickel-diamond matrix for precise cut depth control

- Excellent cut quality with minimal chipping

- Ultra-thin kerfs (<50 microns) for high-precision dicing

- Improved diamond exposure reduces the need for frequent dressing

- Handles high exposure-to-width ratios for stable cutting

- Supports advanced dicing techniques like bevel and step cutting

- Available in various grit sizes and bond types for different applications

- Ideal for silicon, III-V compounds, PZT ceramics, and more

- Ultra-thin kerfs (<50 microns) for high-precision dicing

About Nickel Bond (Electroplated) Tools

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside.Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

NEW GENERATION AND TECHNOLOGY

Tungsten Carbide Dicing Blades

SMART CUT® Series

Tungsten Carbide Slitting / Dicing Blades

SMART CUT® Tungsten Carbide Dicing Blades are expertly crafted for high-precision slitting and cutting applications across various industries. Designed to handle challenging materials with ease, these blades offer exceptional durability and consistent performance. They are ideal for slitting magnetic tape, metal foils, P.E.T., polyester, sheet rubber, fine gauge steel, film, abrasive materials, and paper products, providing clean, precise cuts even in the most demanding applications.

Available in sizes ranging from 40mm to 203mm (8") in diameter, with customizable inside diameters from 0.375” (9.52mm) to 4” (100mm), SMART CUT® Tungsten Carbide Dicing Blades meet the exacting requirements of slitting and dicing tasks.

What are Tungsten Carbide Slicing & Dicing Blades

Tungsten carbide dicing or slitting blades bear some resemblance to diamond cutting blades in terms of their outer diameter (OD), thickness (TH), and inner diameter (ID). However, a significant distinction lies in their cutting mechanism. Unlike diamond blades that use embedded diamonds to grind through materials, tungsten carbide blades are equipped with teeth that slice through the workpiece. This fundamental difference in design affects both their applications and operational parameters.

Design and Operation

These blades are particularly suited for slow-speed cutting machines, typically operating at rotational speeds below 1,000 RPM. The design of tungsten carbide blades incorporates finely crafted teeth, which are essential for the precise cutting of delicate materials. When operated at high speeds, as is common with standard dicing saws designed for diamond blades, the teeth on tungsten carbide blades can suffer immediate damage due to excessive wear and thermal stress.

Application:

-

Green ceramics

Green ceramics

-

Printed Circuit Board (PCB) substrates

Printed Circuit Board (PCB) substrates

-

Fiberglass

Fiberglass

-

Laminates

Laminates

-

Molded Lead Frame Packages (MLP)/Quad Flat No-leads (QFN)

Molded Lead Frame Packages (MLP)/Quad Flat No-leads (QFN)

-

Graphite

Graphite

-

Plastics

Plastics

-

Rubber

Rubber

-

Wood and MDF

Wood and MDF

-

Carbon Fiber

Carbon Fiber

-

Aluminum Foils

Aluminum Foils

-

Copper and Brass Sheets

Copper and Brass Sheets

-

Copper

Copper

-

Aluminum

Aluminum

-

Stainless steel

Stainless steel

-

Resin

Resin

-

Titanium alloy

Titanium alloy

-

Low carbon steel

Low carbon steel

-

Medium carbon steel

Medium carbon steel

Dicing Blade Outside Diameter

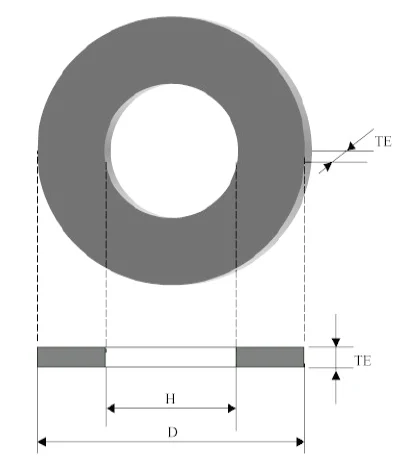

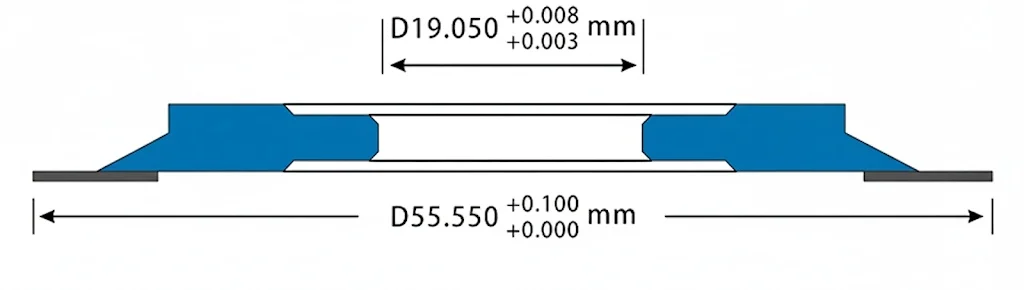

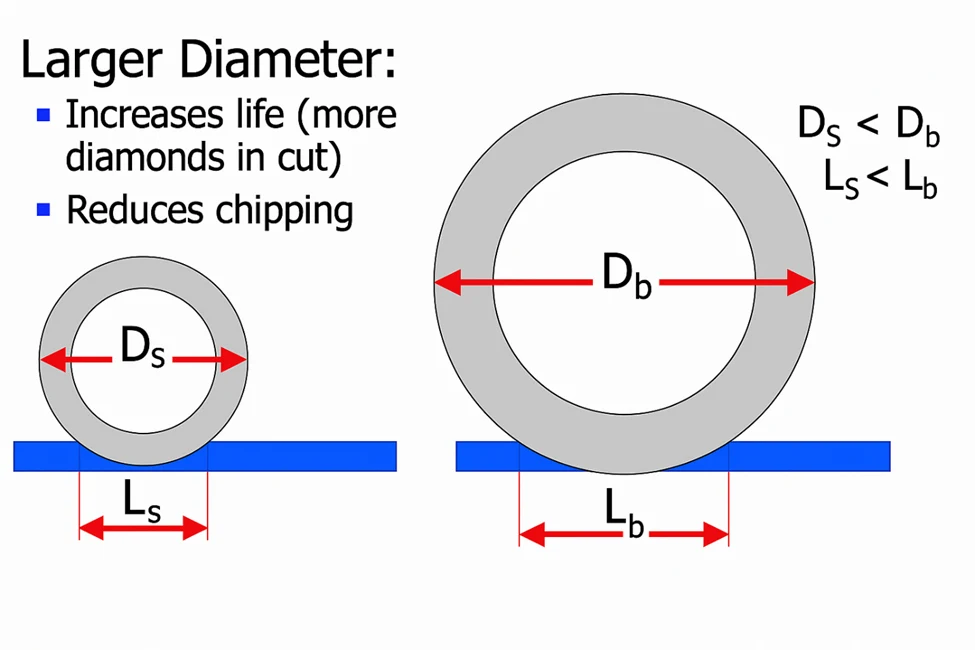

When selecting a dicing blade for your application, diameter is one of the most critical factors to evaluate. For dicing saws, blade diameters usually range between 2″ and 5″. The diameter you choose will determine the maximum cutting depth, spindle speed range, and overall stability of the cutting process.

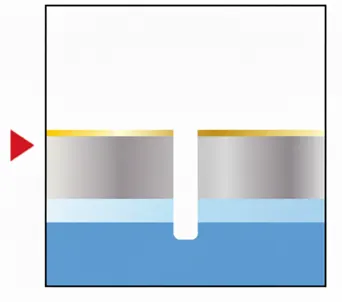

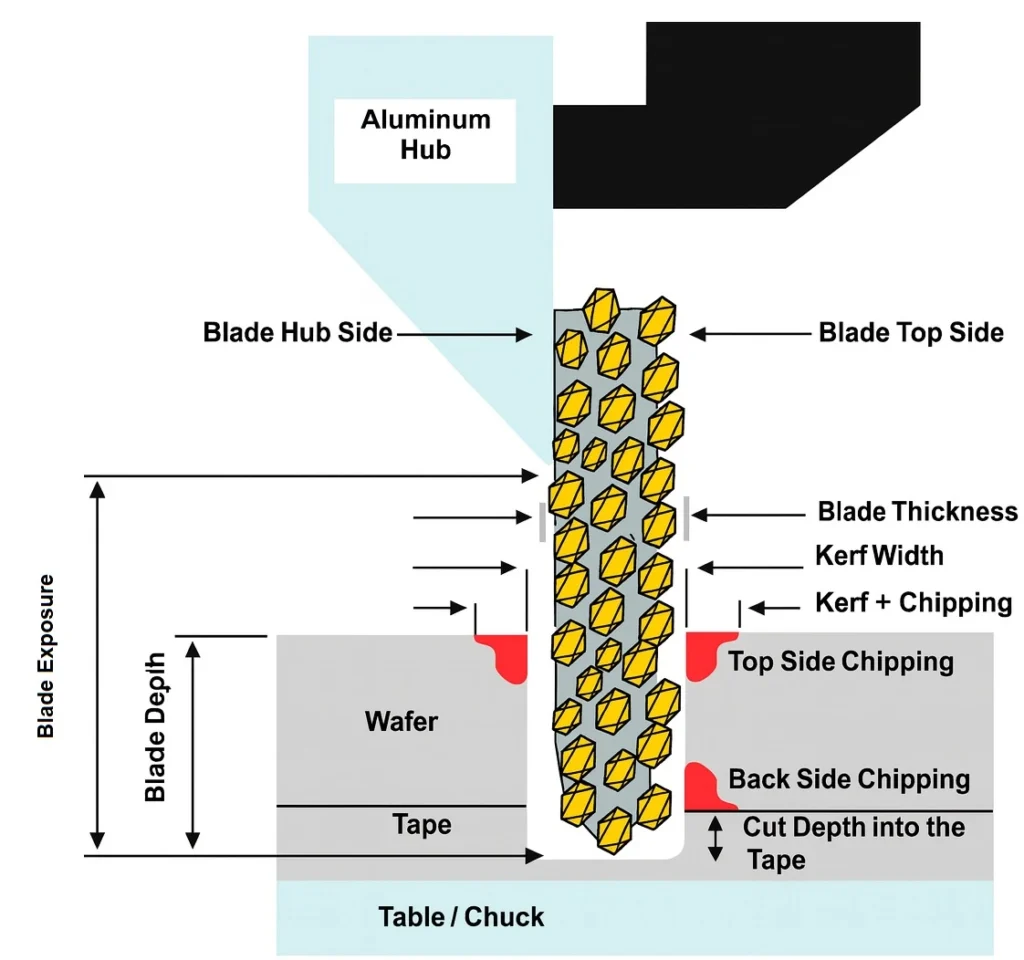

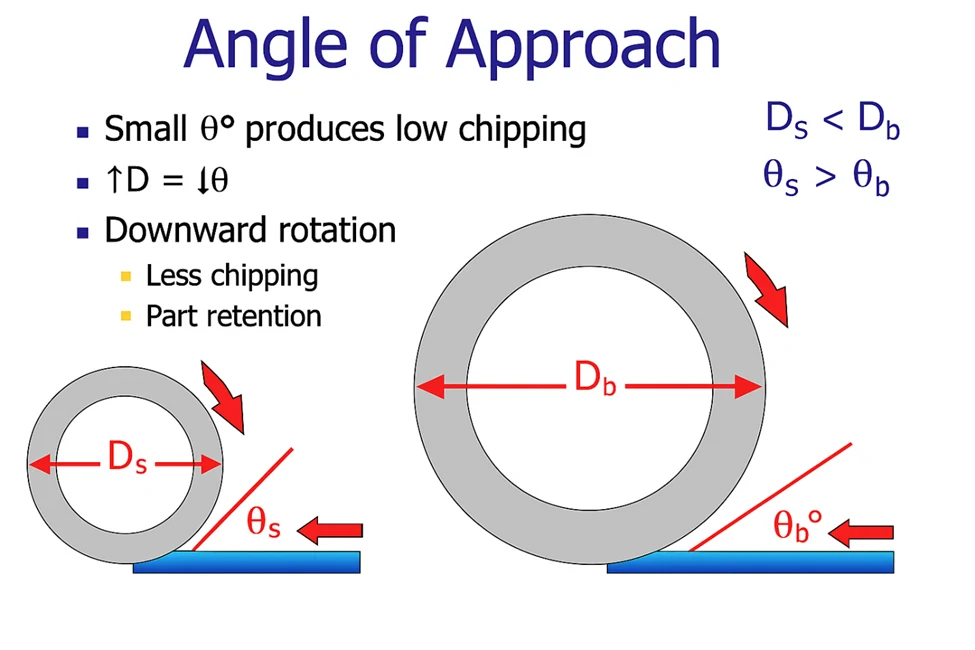

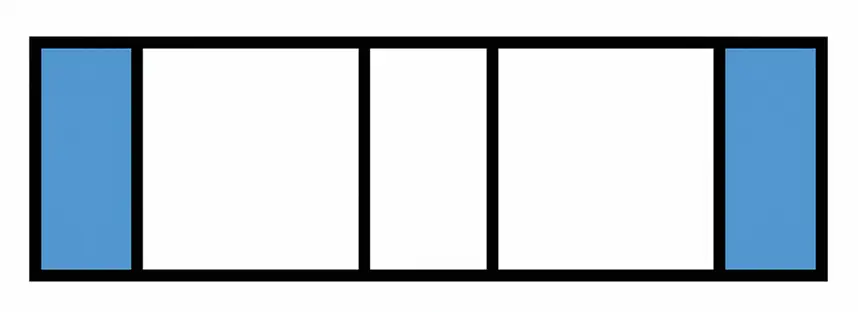

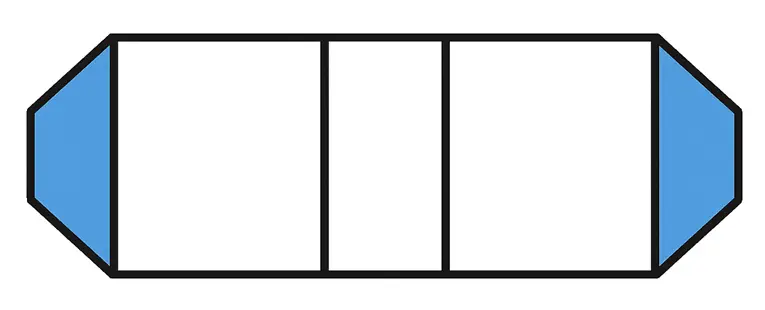

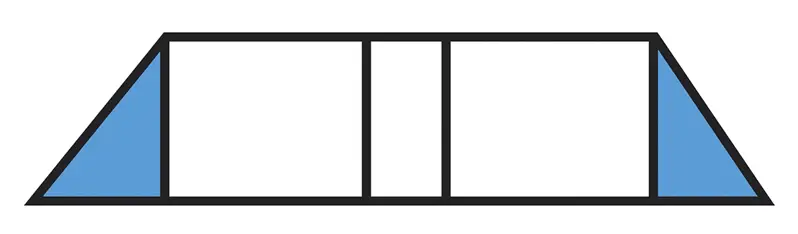

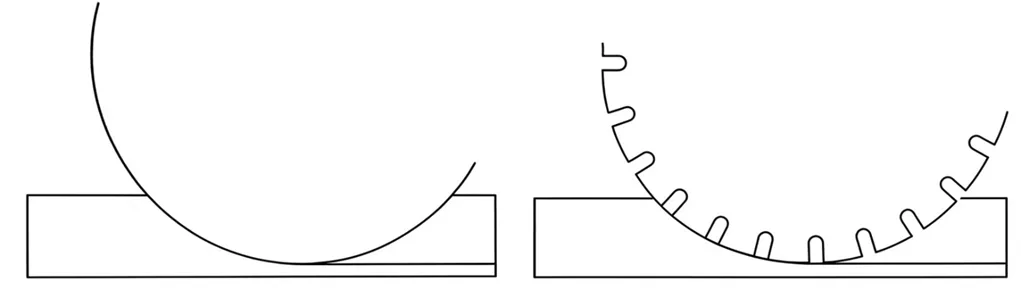

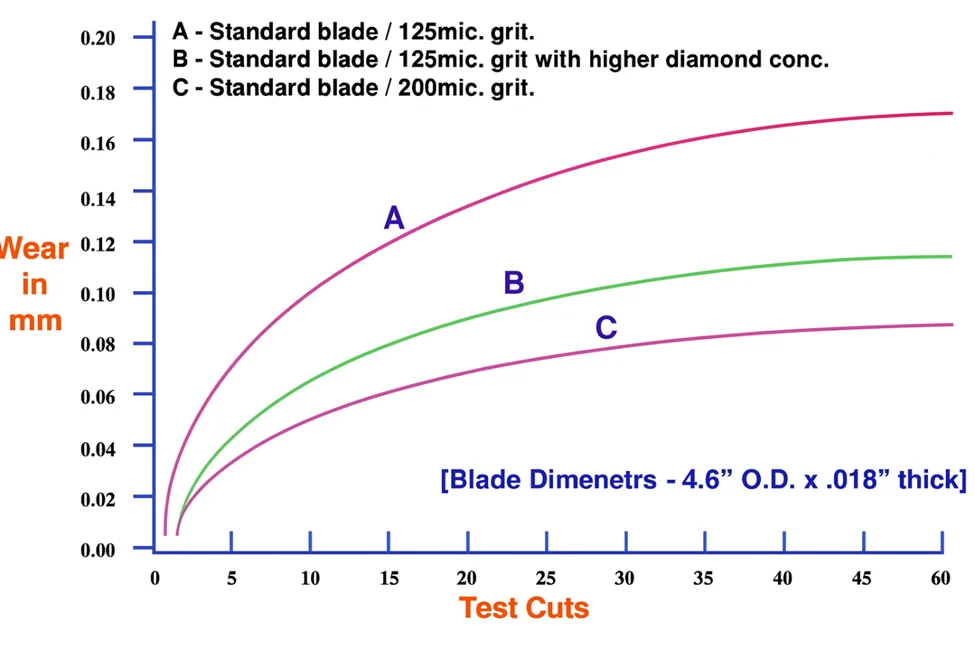

This illustration explains the effect of blade diameter on cutting performance in diamond dicing operations. A larger diameter blade (Db) engages a longer cutting length (Lb) compared to a smaller diameter blade (Ds) with a shorter cutting length (Ls). The increased cutting length means that more diamonds are in contact with the material at any given time, which distributes the load more evenly across the cutting edge. This results in longer blade life and helps to reduce chipping on the workpiece. By contrast, smaller diameter blades concentrate cutting forces over a shorter contact area, leading to faster wear and higher risk of edge damage. Selecting the correct blade diameter based on material thickness, required cut depth, and cut quality is essential for optimizing blade performance and ensuring consistent, high-quality results.

The diagram shows how the angle of approach (θ) changes depending on blade size. With a smaller diameter blade (Ds), the angle of approach (θs) is larger, while with a larger diameter blade (Db), the angle of approach (θb) is smaller. A smaller angle results in less chipping and better part retention, which is why larger diameter blades tend to produce smoother cuts.

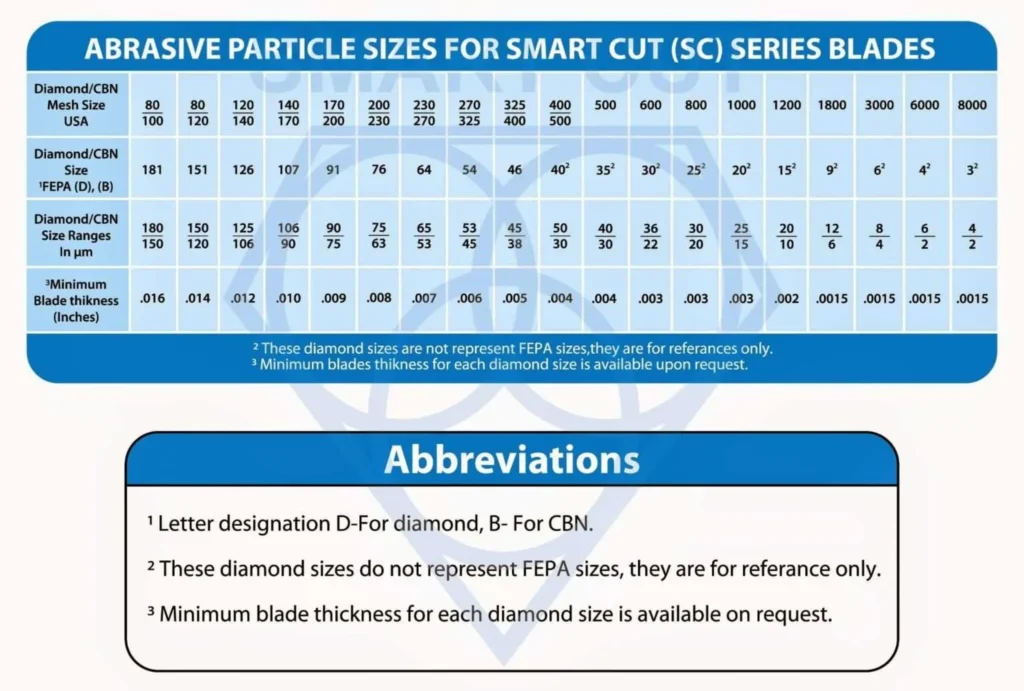

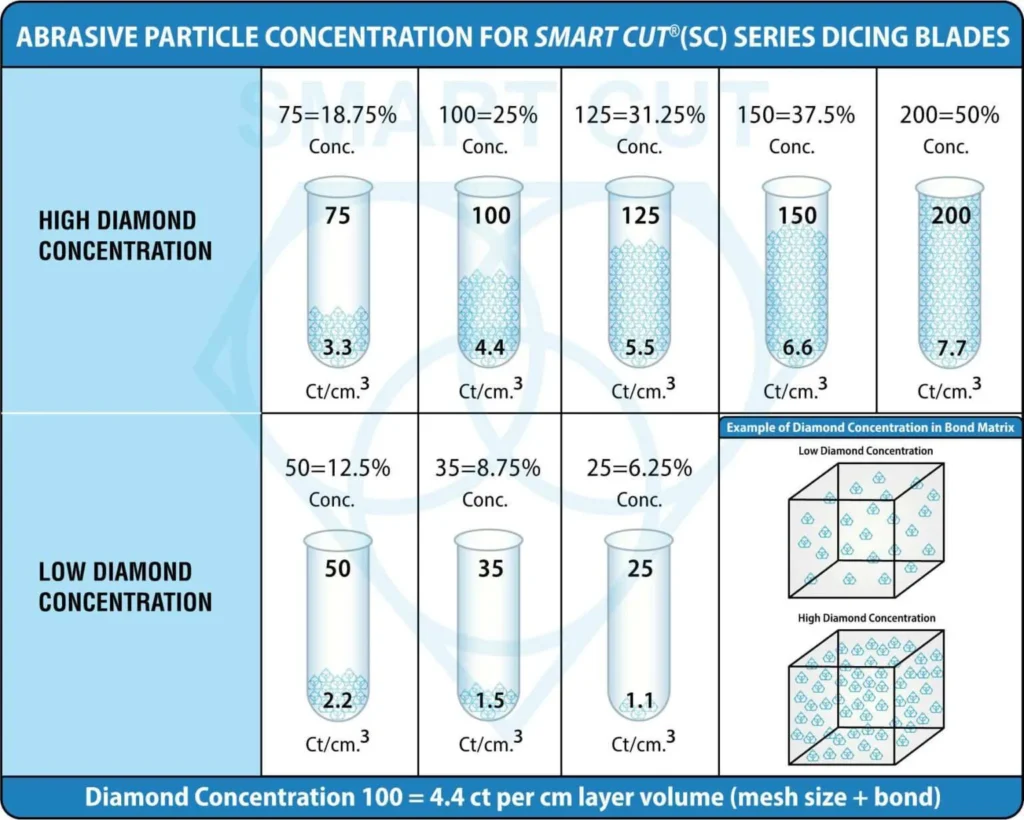

The key point here is that increasing blade diameter reduces the approach angle, leading to improved cut quality and reduced chipping, provided spindle torque and speed are properly adjusted.