Menu

No products in the Quote Basket.

Sign Up to recieve exclusive usage recommendations, illustrated trouble Shooting Guides & sales

9 am to 6 pm PST time

No products in the Quote Basket.

Sintered (Metal Bond) Blades New Generation & Technology

SMART CUT™ series 310M precision sintered (metal bonded) diamond lapidary blades provide unmatched performance for cutting Precious & Semi Precious Stones and also used in art glass applications (cutting flat soda lime and borosilicate glass). Designed for Professionals & Users who understand and appreciate quality.

Manufactured utilizing SMART CUT™ technology, these blades will give you the BEST PERFORMANCE & VALUE FOR YOUR MONEY. Giving you consistent results you can count on everyday. They will last longer & cut faster than ordinary notched, plated, and other sintered (metal bond) lapidary blades.

SMART CUT™ series 310M precision sintered (metal bonded) diamond lapidary blades provide unmatched performance for cutting Precious & Semi Precious Stones and also used in art glass applications (cutting flat soda lime and borosilicate glass). Designed for Professionals & Users who understand and appreciate quality.

Manufactured utilizing SMART CUT™ technology, these blades will give you the BEST PERFORMANCE & VALUE FOR YOUR MONEY. Giving you consistent results you can count on everyday. They will last longer & cut faster than ordinary notched, plated, and other sintered (metal bond) lapidary blades.

SMART CUT™ series 310M precision sintered (metal bonded) diamond lapidary blades provide unmatched performance for cutting Precious & Semi Precious Stones and also used in art glass applications (cutting flat soda lime and borosilicate glass). Designed for Professionals & Users who understand and appreciate quality.

Manufactured utilizing SMART CUT™ technology, these blades will give you the BEST PERFORMANCE & VALUE FOR YOUR MONEY. Giving you consistent results you can count on everyday. They will last longer & cut faster than ordinary notched, plated, and other sintered (metal bond) lapidary blades.

kerf thickness is proportional to diameter of the blade. Thinnest that we can produce is .004″ (0.10mm) in 3″ (75mm) OD. Larger blade diameters such as 4” OD the thinnest kerf thickness is .006” (0.15mm). When we talk about blade thickness we mean actual diamond (kerf thickness) not thickness of the steel core. Which will always be thinner then the diamond section.

0.5mm (12.7mm) is usually the smallest diameter. we can make any increment up to 48”. Minimum order can range from 1 pc, 3 pcs and 20 pcs depending on blade specification

48” this would be segmented (largest continuous rim we can make is 20” (500mm)

we can make any arbor size needed usually same day for a small fee

80/100 mesh (180/150 micron)

yes we can make any thickness you require, please specify. There may a minimum order quantity which can range from 3 pcs to 20 pcs depending on blade specification

Maximum diameter of material can be cut depends on blade diameter, see chart below

There is no specific way to determine specific life of the blades as there are many variables involved. The lifespan of the blade swill depend on lot of different factors such as: Material Hardness, Density, Cutting Depth, Material Shape/Geometry, RPM’s, Feed Rate, Coolant Used, Equipment Type/Condition, Material Holding Method, Operator Experience

tolerance depends on diameter of the blade. For very thin blades usually the tolerance on thickness is + .001”. for thicker kerf thickness blades tolerance on thickness can be + .002”

how fast will they cut?

Cutting speed will depend on material diameter and material properties (hardness, density, shape) and

we recommend flange size at least 1/3 diameter of the blade. The optimal flange size (blade exposure) depends on blade diameter and kerf thickness.

These can be used on lapidary trim and slab saws. As well as tile and other similar cutting machines that can provide the recommended rpm’s range and coolant supply to the cutting zone.

we recommend using water soluable coolant or mineral oil specially if cutting very hard materials. Coolant provides lubrication and reduceds amount of heat generated while cutting. Plain water is not able to provide sufficient lubrication and coolant the blade fast enough. However plain water can be used if needed just the blade may require more dressing and cutting efficiency will not be as affective and life usually shorter

We recommend using 100 grit dressing stick. Alumina oxide or silicon carbide, soft can be used for this purpose.

Depends on materials being cut, dimensions of material rpm’s and coolant used and how effective coolant is reaching the cutting zone. With optimal performance there would be minimal dressing.

no, these must be used with coolant

these blades will outperform all sintered (metal bond) lapidary blades on the market. Please note these are designed specifically for lapidary applications. For other applications we have in stock and produce other blade specifications with different diamond grit sizes, concentrations, bond types, and tolerances

these blades are designed for cutting large variety of ultra hard to soft materials ranging from sapphire and down to glass. We offer many other blade specifications for ultra hard materials such as advanced ceramics, optical glass, composites, glass/quartz tubing etc. Very hard and very brittle materials require finer diamond grit sizes, higher diamond concentrations, different types of diamond, bond composition and bond hardness for optimal performance.

Wheel stiffeners provide stability, rigidity and additional support to your Blade which help prevent the blade from “walking” & loosing its flatness. Diameter of the wheel stiffeners used should minimize the blade exposure & allow to cut material thickness that needed with highest amount of accuracy. Wheel stiffeners may be used without your existing flanges

while there is no specific rule to determine the diameter of the wheel stiffener to be used they should be sufficient enough to minimize the blade exposure. For very thin kerf blades, wheel stiffeners should be 2/3rd the outside Diameter of the Diamond Blade. For thicker and larger blades 1/3 rd the diameter of the blade is sufficient

yes we offer excellent quantity discounts

Yes we can, this is our business

Faster, freer cutting speed, less dressing and longer blade life

The rpm’s are based on diameter of the blade, material type, hardness, thickness. The smaller diameter the blade the faster the rpm’s. The larger the blade diameter the lower the rpm’s

Make sure to use coolant, have coolant sufficiently reaching the cutting zone, use recommended rpm’s, dress the blade when needed, and do not force the blade

You have to feel the blade grind away the material, its something that comes with experience

Concrete, brick/block, and any other abrasive material such as sand stone

tile blades usually have very coarse diamond – such as 40/50 mesh, very low diamond concentration and low to medium diamond quality. They are more cobalt base. Most tile blades are thicker kerf between .050” to .070” kerf thickness. They are designed for cutting softer materials. For cutting hard lapidary materials they would take very long time to go through same amount of material, constantly requiring dressing. If they will cut at all.

For majority lapidary applications the surface finish is very smooth, that secondary finishing operations are not required

Its pretty simple. Just push the material into the rotating blade. You will feel the diamond cut through at its own pace

They cut faster, freer, and last longer

Possibly, we have some distributors in different countries

We can ship to almost any country that is not restricted by the US government. We can use almost any shipping method such as US air mail, dhl, ups, fed ex, ups and others

Designed for cutting a large variety of precious & semi precious stones, gem stones, colored stones, lapidary materials, rocks, glass and similar materials from up to 9.0 on mohes scale fast & easy.

Image | Item No. | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

UKAMDRST4 | $15.39 | Max: Min: 1 Step: 1 | |||

UKAMDRST7 | $15.99 | Max: Min: 1 Step: 1 | |||

SMARTC1G | $34.81 | Max: Min: 1 Step: 1 | |||

UKAMDRST5 | $39.47 | Max: Min: 1 Step: 1 | |||

UKAMDRST8 | $39.47 | Max: Min: 1 Step: 1 | |||

SMARTC2G | $99.81 | Max: Min: 1 Step: 1 | |||

SMARTC4A | $317.41 | Max: Min: 1 Step: 1 | |||

SMARTC7A | $1,745.00 | Max: Min: 1 Step: 1 |

Image | Name | Diameter | Inside Diameter | Description | Price | Quantity | Add to cart | |

|---|---|---|---|---|---|---|---|---|

30mm | 1/2″ | Flanges for Accessories | $70.00 | Max: Min: 1 Step: 1 | ||||

30mm | 5/8″ | Flanges for Accessories | $70.00 | Max: Min: 1 Step: 1 | ||||

40mm | 1/2″ | Flanges for Accessories | $75.00 | Max: Min: 1 Step: 1 | ||||

40mm | 5/8″ | Flanges for Accessories | $75.00 | Max: Min: 1 Step: 1 | ||||

45mm | 1/2″ | Flanges for Accessories | $80.00 | Max: Min: 1 Step: 1 | ||||

45mm | 5/8″ | Flanges for Accessories | $80.00 | Max: Min: 1 Step: 1 |

| Blade Diameter | Recommended RPM | Blade Diameter | Recommended RPM |

|---|---|---|---|

| 4″ (100mm) | 4,000 | 16″ (400mm) | 1,000 |

| 5″ (125mm) | 3,438 | 18″ (450mm) | 1,000 |

| 6″ (150mm) | 2,675 | 20″ (500mm) | 900 |

| 8″ (200mm) | 2,000 | 22″ (550mm) | 825 |

| 10″ (250mm) | 1,600 | 24″ (600mm) | 700 |

| 12″ (300mm) | 1,325 | 30″ (762mm) | 550 |

| 14″ (350mm) | 1,140 | 36″ (914mm) | 500 |

Best performance and life will result when the blades are operated in the range of 3150 to 500 surface feet per minute. Optimum performance and life will be obtained at the 5000 s.f.m. For your convenience we present the following chart of optimum RPM of shaft for each blade size.

Any diamond blade may occasionally require dressing of the edge to remove surplus metal or glazing to expose new diamond particles. You can dress by making a few cuts in an old 220 grit grinding wheel or a dressing stick made specifically for this purpose. Use coolant with this procedure. The SMART CUT diamond bond is designed to minimize this procedure. By using enough coolant and following the suggested procedures, you can’t rest assured this will require the minimal amount of time as compared to most blades.

Disposing of coolant used in lapidary work, such as water or water-based cutting fluids, should be done in an environmentally responsible manner. Follow these steps to properly dispose of coolant after cutting lapidary materials:

Consult our Illustrated Diamond Blade Trouble Shooting Guide which shows all the possible issues people experience when using blades and how to fix and prevent them

Image | Item | Diameter OD | Diamond Thickness TH | Diamond Height | Arbor ID | Suggested List Price | Internet Price (1pc) | 3 pcs (each) | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|

23 4671W | 4" (101.6mm) | .020" (0.5mm) | .20" (5mm) | 5/8-1/2" B | $60.00 | $47.00 | $39.00 | Max: Min: 1 Step: 1 | ||

23 4673W | 6" (152.4mm) | .014" (0.35mm) | .20" (5mm) | 5/8" B | $64.00 | $54.00 | $47.00 | Max: Min: 1 Step: 1 | ||

23-4673W1 | 6" (152.4mm) | .014" (0.35mm) | .20" (5mm) | 1/2" | $64.00 | $54.00 | $47.00 | Max: Min: 1 Step: 1 | ||

23-4674W | 6" (152.4mm) | .020" (0.5mm) | .276" (7mm) | 5/8-1/2" B | $68.00 | $56.00 | Max: Min: 1 Step: 1 | |||

23-4678W | 8" (203.2mmm) | .025" (0. 6mm) | .276" (7mm) | 5/8-1/2" B | $79.00 | $59.00 | Max: Min: 1 Step: 1 | |||

23-4679W | 8" (203.2mm) | .032" (0. 8mm) | .276" (7mm) | 5/8-1/2" B | $80.00 | $61.00 | Max: Min: 1 Step: 1 | |||

23-4675W | 6" (152.4mm) | .032" (0. 8mm) | .276" (7mm) | 5/8-1/2" B | $70.00 | $64.00 | $51.00 | Max: Min: 1 Step: 1 | ||

23-4713W | 10" (254mm) | .060" (1.52mm) | .314"(10mm) | 5/8" | $114.00 | $94.50 | $84.00 | Max: Min: 1 Step: 1 | ||

23-4716AW | 12" (300mm) | .085" (2.16mm) | .394" (10mm) | 1" B to 3/4" | $198.00 | $178.00 | $165.00 | Max: Min: 1 Step: 1 | ||

23-4716W | 12" (300mm) | .0512" (1.3mm) | .394" (10mm) | 1" B to 3/4" | $225.00 | $198.00 | $180.00 | Max: Min: 1 Step: 1 | ||

23-4717AW | 14" (350mm) | .085" (2.16mm) | .394" (10mm) | 1" B to 3/4" | $235.00 | $210.00 | $190.00 | Max: Min: 1 Step: 1 | ||

23-4717W | 14" (350mm) | .0512" (1.3mm) | .394" (10mm) | 1" B to 3/4" | $250.00 | $225.00 | $205.00 | Max: Min: 1 Step: 1 | ||

23-4728AW | 16" (400mm) | .085" (2.16mm) | .394" (10mm) | 1" B to 3/4" | $255.00 | $234.00 | $215.00 | Max: Min: 1 Step: 1 | ||

23-4718W | 16" (400mm) | .0512"(1.0mm) | .394" (10mm) | 1" B to 3/4" | $285.00 | $265.00 | $215.00 | Max: Min: 1 Step: 1 |

Designed for cutting a large variety of precious & semi precious stones, gem stones, colored stones, lapidary materials, rocks, glass and similar materials from up to 9.0 on mohes scale fast & easy.

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT ® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

UKA India Superhard Tools is one of the application Producing bades sold under private for a number of well known equipment methods, modem quality contul methods that affect diamond to equality of out, and cont performance Discover why some of the Leading manufacturers to Professional Lady H around the world prefer SMART CUT damond tools

SMART CUT series 310M blades are designed to work on vitually any material you can find. You can cut very hard materials up to hardness of sapphire than switch to cutting very soft materials and the blade will maintain the same consistent performance

Blade life is 80% to 40% longer compared to other conventional sintered blades

Blade life is 80% to 40% longer compared to other conventional sintered blades

THINNEST Sintered (metal bond) Diamond Blades commercially available for lapidary (precious & semi precious stone) application! The Diamond Thickness (TH) specified is actual thickness of diamond section, not core thickness. If you are cutting valuable materials or just want to have thinner kerf blade there is no substitute for these blades

Diamond & CBN lapidary blades with SMART CUT technology require minimum dressing, the bond renews itself.

Diamond lapidary blades made utilizing SMART CUT technology are much more aggressive than your conventional lapidary blades. They can cut faster, while still leaving behind a smooth finish free of material deformation.

In most cases lapidary blades manufactured utilizing SMART CUT technology, will outlast other conventional lapidary blades. SMART CUT lapidary blades are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

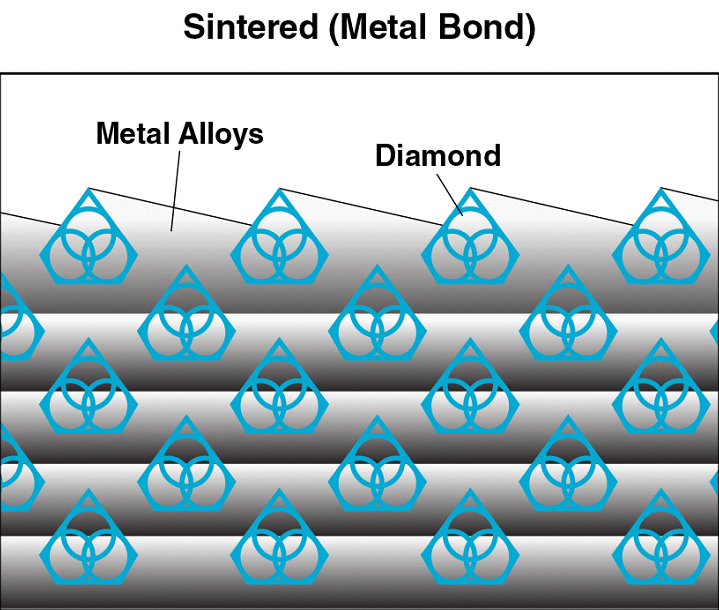

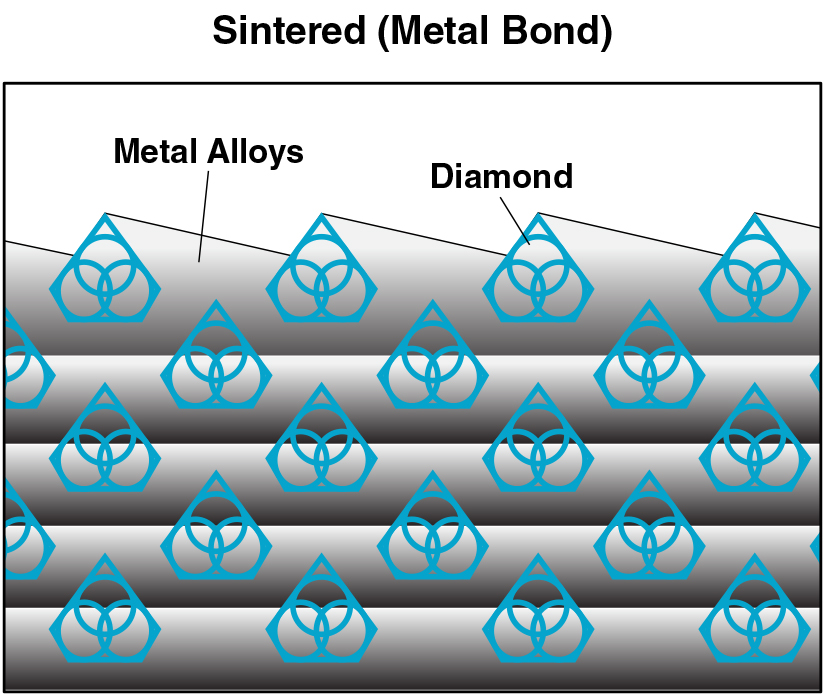

SMART CUT Series 310M Sintered (Metal Bond) Diamond Lapidary Blades have hundreds of diamond layers impregnated inside the metal matrix. Unlike Many Other Blade Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

SMART CUT Series 310M Sintered (metal bond) Lapidary blades are the best investment you can make! Although they may cost more than other sintered (metal bond), electroplated (nickel bond), hot or cold rolled or some notched lapidary blades. Designed for users that understand and appreciate quality. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

SMART CUT Series 310M Lapidary Blades open bond design have diamonds oriented and evenly distributed in a bond matrix. Providing faster, freer cutting action with minimum heat generation. This translates in improved surface finish and minimum chipping.

Any other blade have 5mm diamond depth/height. This has remained industry standard for many decades. While this is sufficient for most people. The return on investment (ROI) can be lot higher

Diamond depth (height) indicates the height of diamond section/layer extends from the steel core. The higher the diamond depth, the longer the blade life (in most cases). Diamond height will vary depending on the blade diameter and thickness. In the past there was direct correlation between diamond depth and blade price. The higher the diamond height, the higher the blade price. Today advanced in industrial diamond powder and blade manufacturing technology has significantly reduced the cost of industrial diamond to the point that its only a small part of the overall manufacturing cost equation.

Diamond depth (height) indicates the height of diamond section/layer extends from the steel core. The higher the diamond depth, the longer the blade life (in most cases). Diamond height will vary depending on the blade diameter and thickness. In the past there was direct correlation between diamond depth and blade price. The higher the diamond height, the higher the blade price. Today advanced in industrial diamond powder and blade manufacturing technology has significantly reduced the cost of industrial diamond to the point that its only a small part of the overall manufacturing cost equation.7mm to 10mm in on order to provide longest life and best value/RPI possible for your blade investment.

The longer life can be attributed not only the higher diamond depth, but to higher diamond quality used. Advanced diamond distribution an orientation techniques, and proprietary bond chemistry. Combined with our competitive prices you re sure to obtain the best value and return on investment possible

Sintered (Metal bonded) diamond blades are “impregnated” with diamonds. Diamonds sintered and multiple (hundreds) layers of diamonds impregnated inside the metal matrix. Electroplated and other types of diamond blades for lapidary application have only one layer of diamond that stays on the surface. Diamonds in a sintered (metal bond) diamond blade are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. The compacted materials are then hot pressed or sintered to full density. Heating rate, applied pressure, sintering temperature and holding time, are all controlled according to the matrix composition. This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance possible on any materials such as sapphire, agate, emerald, ruby, opal, petrified wood, glass, and etc.

The metal bond surrounding the diamonds must wear away to continuously keep re-exposing the diamonds for the diamond tool to continue cutting.

Sintered (metal bonded) diamond tools are recommended for cutting hard materials from 45 to 75 on Rockwell Scale (5 to 9.5 on mohs scale of hardness). It is more wear resistant and holds diamond well in place, usually producing the highest yield/cutting & best price per cut ratio.

They will last longer & cut faster than ordinary notched, plated, and other sintered (metal bond) lapidary blades.

They wear evenly, and are known for their long life & consistency. Sintered (metal bonded) diamond blades are the latest technology available in Diamond Blades. And represent the BEST VALUE & PERFORMANCE PER CUT.

They will last longer & cut faster than ordinary notched, plated, and other sintered (metal bond) lapidary blades.

Sintered (metal bonded) lapidary blades are the best investment you can make! Although they may cost more than electroplated (nickel bond), hot or colled rolled or some notched lapidary blades, sintered (metal bond) blades will more than pay for themselves in terms of:

Other Bond type blades may cost less, and at first glance may seem like the most cost effective alternative. However, they will cost you more in the long run. Depending on material and application, sintered (metal bonded) blades may last as much as 50 to 100 other diamond lapidary blade types put together. You can’t get more life out of any other blade !!! Instead of constantly putting blades on and off the saw, you will save money by using one blade. This means cost per cut, sintered (metal bond) blades are the best choice

Other Blade Types have only one layer of diamond coated on metal core. Diamonds sit only on the surface. When this diamond portion is peeled off, the blade will slow down, cut on the side (not cut straight) or stop working (cutting) altogether. While other blade types may provide acceptable level of performance softer lapidary materials such as topaz, turquoise, amethyst, and etc. They will immediately burn out on harder materials such as agates, petrified wood, sapphire and etc. Metal bonded blades are sintered and impregnated inside the metal matrix. Multiple (hundreds) layers of diamonds are impregnated inside the metal matrix. Unlike Blade Types, metal bond blades wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance from sintered (metal bonded) blades.

Sintered (Metal bond) Multiple Layers of diamonds embedded in a very soft metal matrix

Sintered (Metal bond) Multiple Layers of diamonds embedded in a medium soft metal matrix

Sintered (Metal bond) Multiple Layers of diamonds embedded in a medium to hard metal matrix

Electroplated (Nickel Bond) Single Layer of Diamonds in Nickel Matrix

Notched Rim Serrated or notched edge filled with diamond

Thin to Thick

Thin to Thick

Thick

Very Thin To Medium

Very Thin To Medium

Medium / Coarse

Medium / Coarse

Very Coarse

Medium

Medium

Very High

Medium

Low

Low

Very Low

25 to 200 con

5mm

10 to 5mm

Diamond coating on surface

±0.05mm to ±0.1mm

±0.05mm to ±0.1mm

±0.2mm to ±0.5mm

±0.1mm

±0.1mm to ± 0.2mm

Yes

NO

NO

NO

NO

0.015mm

0.03mm

0.05mm

Good

Good

Yes

Good

Poor

Good

Satisfactory

Excellent/ Very Fast

Good (Moderate to Fast)

Poor (Slow)

Excellent (very fast) in begging

Good

Excellent

Good

Poor

Poor

Medium

Very Frequent

Minimum

Minimum

Minimum

Medium

High

Minimum

Minimum

Excellent

Very Good

Poor

Good

Satisfactory

Higher

Medium

Low

Medium/Low

Very Low

Yes

Yes

No

No

No

In redesigning and updating our original sintered (metal bond) lapidary thin kerf blade, we wanted to give our customers something more, something better than anyone could give them, something they always wanted and could not get before.

We did some serious research. We talked to the experts. Serious users, both professional gem cutters, lapidaries, and rockhounds. People like yourself.

The people who use diamond blades everyday, every chance they get. The people who complain and professionals who know what to look for in a diamond blade to get the job done right. We wanted to know what and why they liked about the diamond blades they used. What they don’t like, what they want, and what they weren’t getting.

So with this in mind, in 1994 we spend over 4 years in research and development making our popular sintered (metal bond) thin kerf blades even more superior. Following the suggestions of customers like you, we took the best features and advantages the sintered (metal bond) thin kerf blades had to offer to create next generation of the SMART CUT series 310M blade.

Are you using the right blade for your application?

many Clients wast valueable time & money by using incorrect blades for their application.

Learn what variables you should consider when chosing your next lapidary blade

Diamond Concentration is still a factor in determining the life and cutting speed of your Diamond Lapidary Blade. Higher diamond concentration is recommended and usually used for cutting softer and more abrasive types of materials. However, the trade off is slower cutting speed. Low diamond concentration is recommended and widely used for cutting harder materials

Lapidary blade thickness typically ranges from .014” (0.35mm) to .085” (2.0mm). Thinner and thicker wafering blade are available, frequently from stock upon request. Kef thickness typically increases with blade diameter (in proportion to diameter of the blade). Kerf is the amount of material removed from the material due to the thickness of blade passing though the material. Blade thickness is important for users requiring most minimal amount of material loss cutting specially when cutting very valuable materials such as gemstones or meteorites There are large variety of factors that will contribute to optimal blade thickness for your material/application Including your desired cutting speed, feed rate, material diameter, thickness, hardness, density, and shape. As well as skill & experience of the operator. Thicker blades are more stiff and can whistand higher/feed rates. Another advantage of thicker kerf blades is they are more forgiving to operator error and abuse. Thicker kerf blade are recommended for use in environment where large number of individuals will be sharing and using same equipment. Perfect for less experienced and novice saw operators, such as students and beginning users.

Feed rate is amount of force applied to the blade to go through material being cut. This will typically vary depending on blade diameter, kerf thickness & material being cut. Generally, harder materials are cut at higher feed rates and speeds (such a precious and semi precious stones) and more softer and brittle materials are cut at lower loads and speeds (such as glass, quartz). The Speeds/RPM’s you are using, shape/geometry of the material, and how the specimen is being clamped/hold in place will affect the load that can be used for your application.

Most lapidary blades are used between 4,000 to 1,000 RPM’s Typically harder and more denser materials such as Sapphire, are cut at higher RPM’s/speeds Where more brittle materials such as as glass are cutting at lower RPM’s. Most rim saws RPM’s are typically limited from 1,000 to 4,000 RPM’s. Slabbing saws 500 to 1000 rpm’s. And trim saws from 3,000 to 6,000 rpm’s.

Diamond Mesh Size plays a major role in determining your cutting speed, cut quality/surface finish, level of chipping you will obtain. Diamond Mesh size does have considerable effect on cutting speed. Coarse Diamonds are larger than finer diamonds and will cut faster. However, the tradeoff is increase in chipping and surface finish. If you are cutting fragile, more delicate materials then we have available from stock finer mesh size diamond blades. If you need to cut as fast as possible and surface finish is not a concern we also offer much coarser cutting blades for this application.

Ability of the bond matrix to hold diamonds. As the hardness of the bond is increased, its diamond retention capabilities increase as well. However the trade off is slower cutting speed. Life of the diamond blade is usually increased with hardness of its bond matrix. Bonds are designated on their scale of hardness from Soft, Medium, and Hard. There are dozens of variations and classification schemes based on bond degree of hardness or softness. Using diamond blades with optimum bond hardness for your application is important to successful precision diamond sawing operation. Bond matrix that is too soft for the material being cut will release diamond particles faster than needed, resulting in faster wear and shorter diamond blade life. On other hand bond matrix that is too hard will result in much slower cutting speeds and require constant dressing to expose the next diamond layer. As rule of thumb, harder materials such as sapphire generally require a softer bond. Whereas softer and more brittle materials require a harder bond.

Typically lapidary blade diameters range form 4” (100mm) to 8” (200mm) for trimming and 10” (254mm) and up are usually used for slabbing. The diameter should be selected based on material diameter and thickness being cut. Smaller diameter blades are thinner than the larger diameter blades and are more prone to bending and warping. Although large diameter blades are thicker, they are typically used for cutting larger and pieces of material at higher loads and speeds than smaller blades Blade Inside Diameter - Most trim saws and tile saws has 5/8” arbor these are for blades 4” to 10” OD. Larger cutting machines such as 12” to 18” OD usually have 1” arbor. We can provide bushings to smaller arbor. We can also expand the current arbor size to anything you want same day.

Metal bonding offers long life and durability, and is the best bond type to use for lapidary applications.

We understand that your success depends on select the right dicing blade, and optimizing your dicing parameters to best fit your applications/needs. The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

SMART CUTTM Series - 330MS Wide Slot Segment Design - Diamond Depth (Height): 8mm SMART CUT Series 330MS Wide spacing between segments. Designed for fast and more aggressive cutting, where chipping and very smooth cut loss is not essential. And loss of material is not critical. Perfect for medium to hard lapidary materials, and less experienced blade users.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales