-

0 items in quote

No products in the Quote Basket.

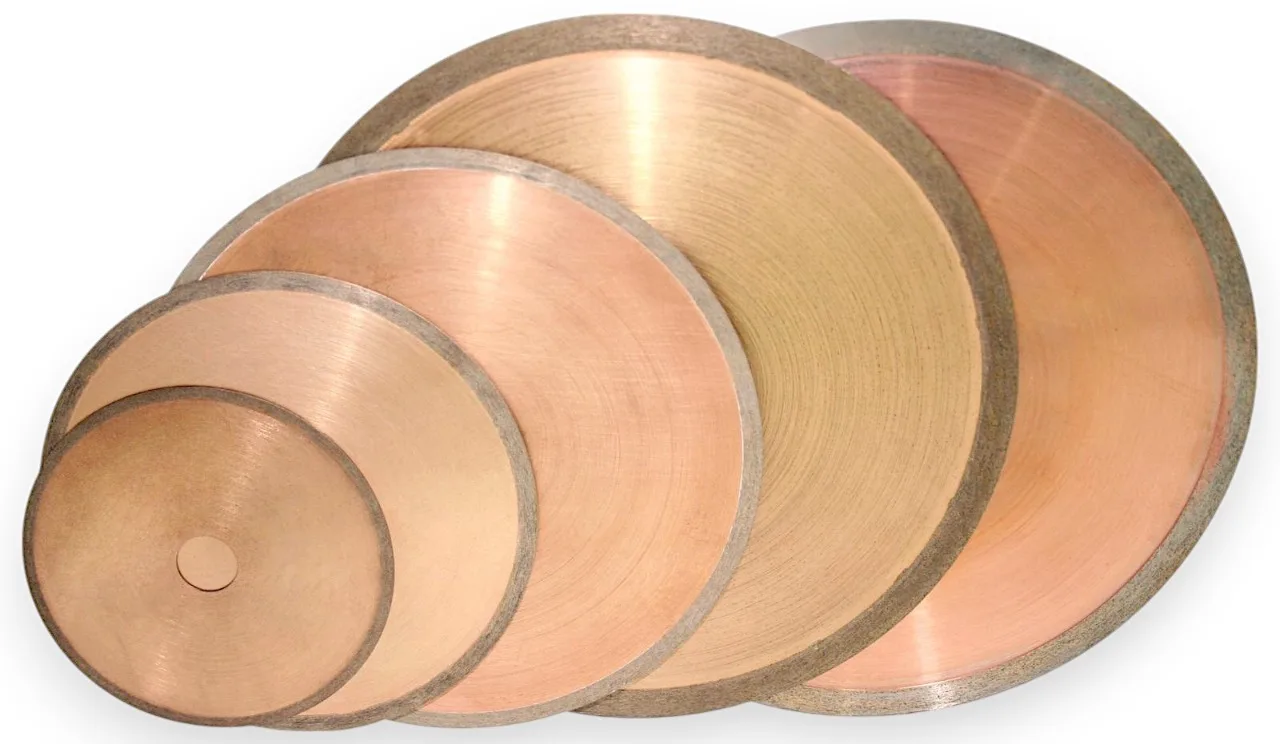

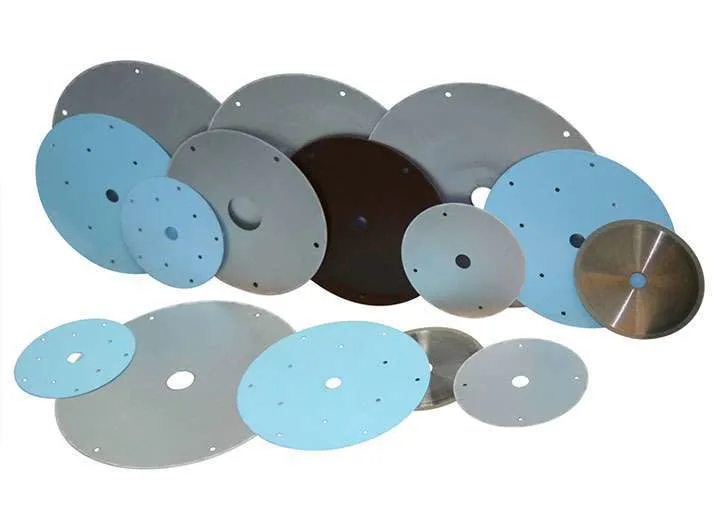

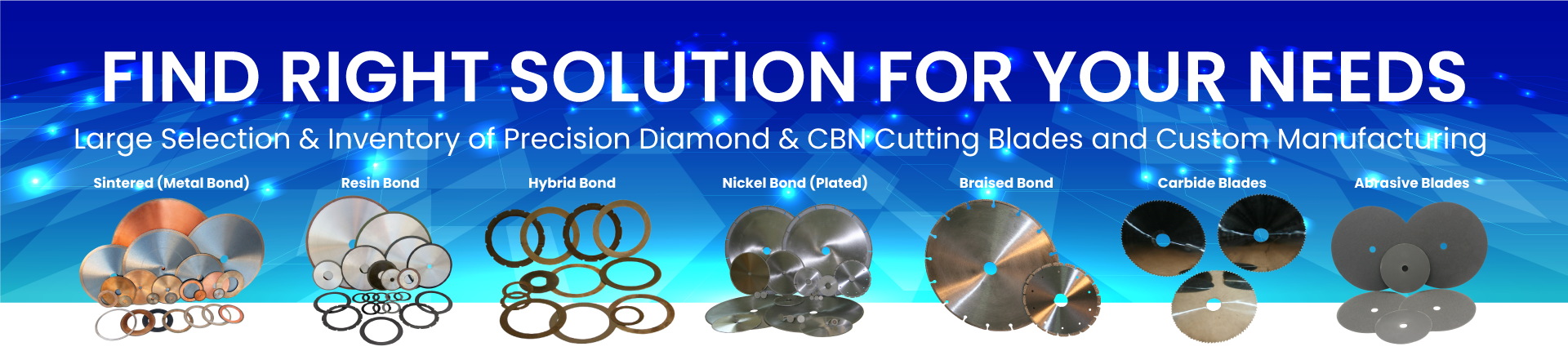

SMART CUT® DIAMOND WAFERING BLADES SINTERED (METAL BOND)

SMART CUT® Precision Diamond & CBN Wafering Blades are designed and specially selected to provide the maximum possible blade life for your desired cut quality and speed.

Compare to any other brand name Diamond Wafering Blades such as:

BUEHLER, STRUERS, LECO & Many Others

COMPARABLE QUALITY – SIGNIFICANTLY LOWER

(Manufacturers Direct Prices)

DESCRIPTION

SPECIFICATIONS

INDUSTRIES USED IN

FAQ

ACCESSORIES

USAGE RECOMENDATION

DESCRIPTION

Diamond & CBN Wafering Blades (Laboratory Grade)

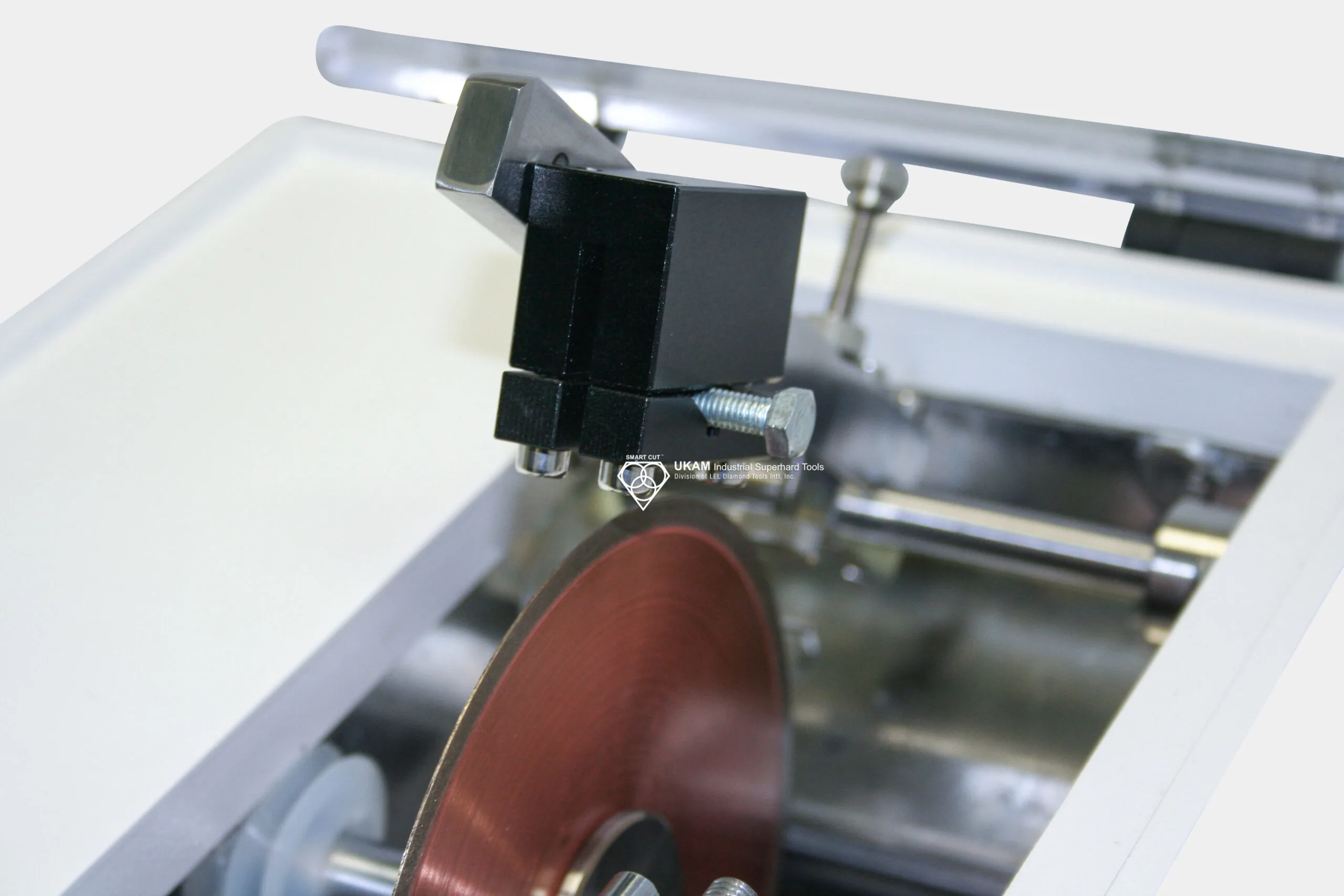

SMART CUT® Precision New Generation Sintered (metal bonded) Diamond & CBN Wafering Blades are the highest overall performance blades available today. Designed specifically for Sample Preparation & Materials Research. Manufactured utilizing SMART CUT® technology, giving you consistent results you can count on everyday. Wafering Blades are available from inventory in many different diamond concentrations, mesh sizes, bond hardness, & inside diameters. Available from stock for any manufacturers low or high speed sectioning/wafering saw. We will work with you to determine your needs, and recommend the right parameters for your specific material/application.

Compare to any other brand name Diamond Wafering Blades such as: BUEHLER, STRUERS, LECO & Many Others. If you are not using these blades, you are paying too much & missing out on incredible performance.

DIAMOND WAFERING BLADE SERIES DESIGNATION

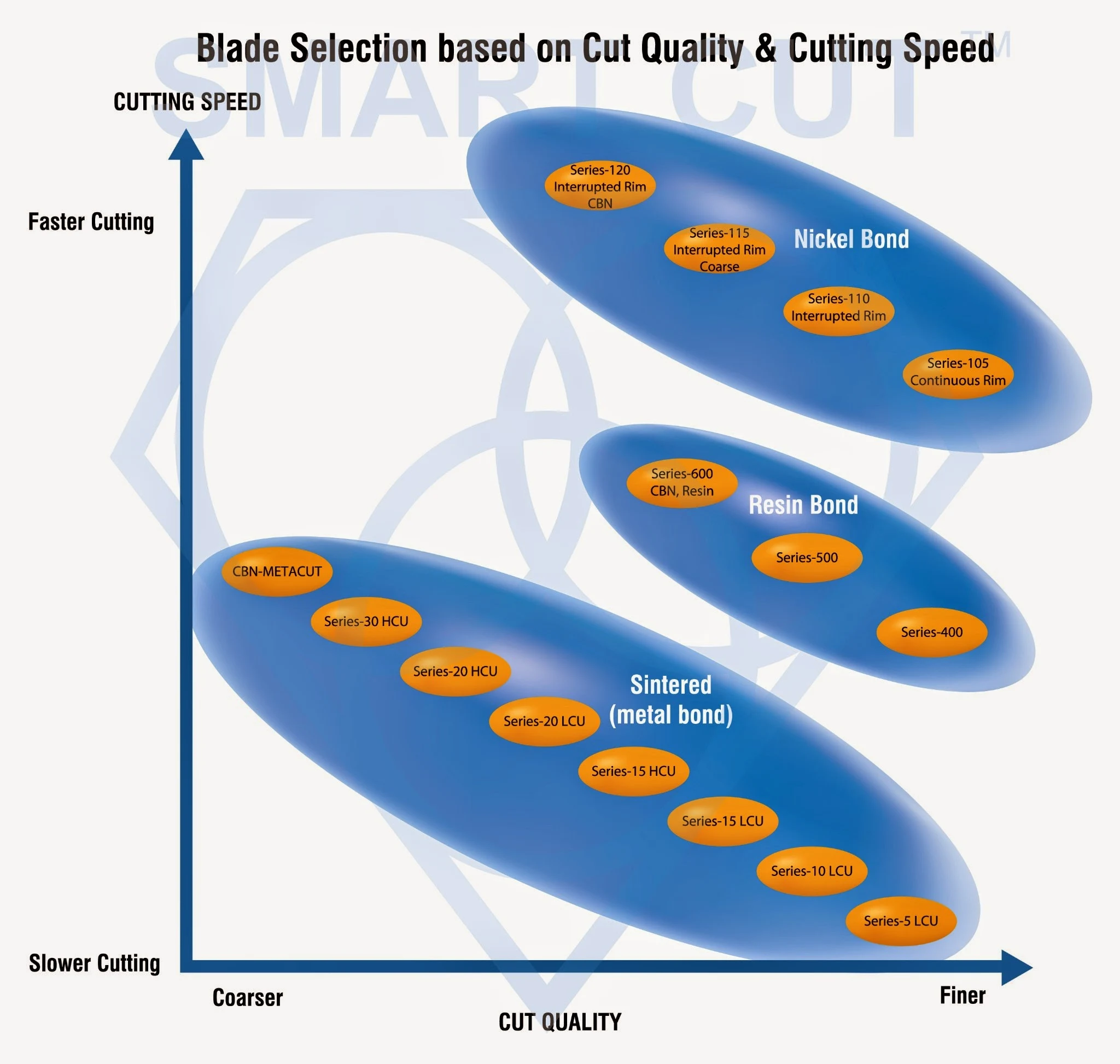

Diamond wafering blades are available with large variety of diamond mesh / particle sizes using a scale from 5 (finest) to 30 (coarsest). A diamond wafering blade with number 10 will have larger diamond particles than wafering blade with rating of No. 5. yet they are not necessarily twice as large. A general rule of thumb is the smaller the diamond particles/crystals the lower the resulting deformation. However this is not always the case and depends on material being sectioned. A number of materials require larger diamond particle size to be cut effectively and economically. Using smaller size diamonds would not be economical and create large material deformation.

SPECIFICATIONS

- Bond Type: Sintered (Metal Bond)

- Outside Diameter: 3″ (75mm) to 8″ (203mm)

- Kerf Thickness: .004″ (0.1mm) to .035″ (0.8mm)

- Inside Diameter (Arbor Size): 1/2″ (12.7mm) – other arbor sizes can be machined usually same day

- Diamond Size: 60 to 400 mesh

- Blade Series: 30HCU, 20HCU, 20LCU, 15LCU, 15HCU, 10LCU, 5LCU

- Diamond Concentration: Low (50 con) and High (100 con)

- Diamond Depth / Height: 4mm or 5mm

- Blade Type: 1A1R and 1A8

- Core Type: Steel (40 to 50 on Rockwell scale of hardness)

- RPM’s Range: 25 to 12,500

- Load / Feed Rate:0.1 mm/s to 1 mm/s

- Coolants Used: Water Soluble, Oil, Water, Dry (in certain cases)

- Equipment Used On: Low Speed Saws, Medium Speed Saws, High Speed Saws, Laboratory Saws, & Many Other Equipment

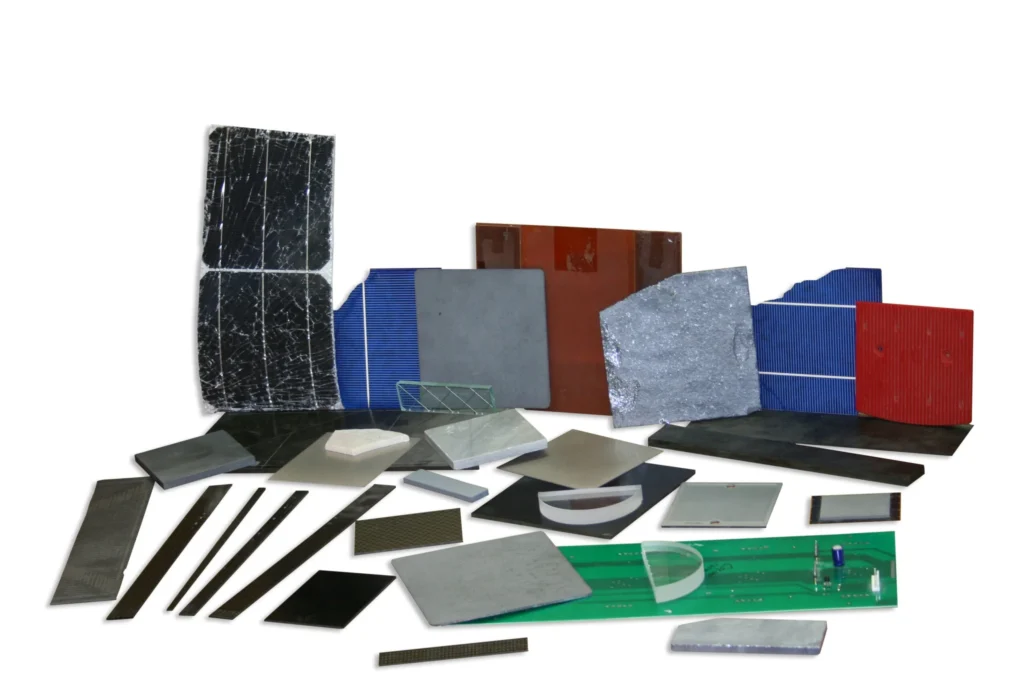

- Materials / Samples Used On: almost any material / sample type

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

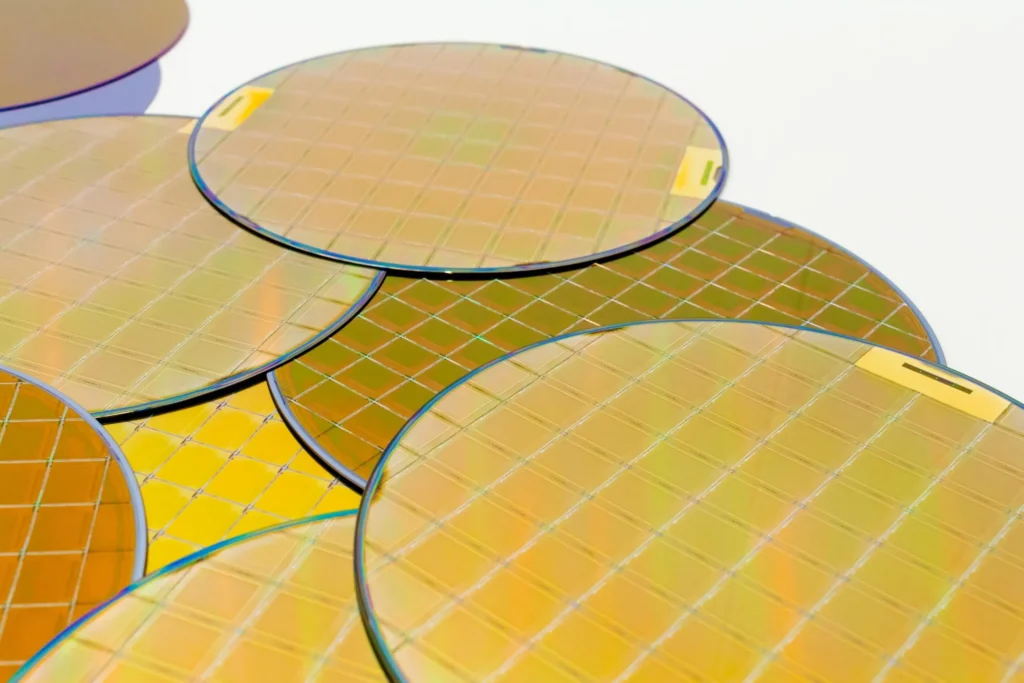

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

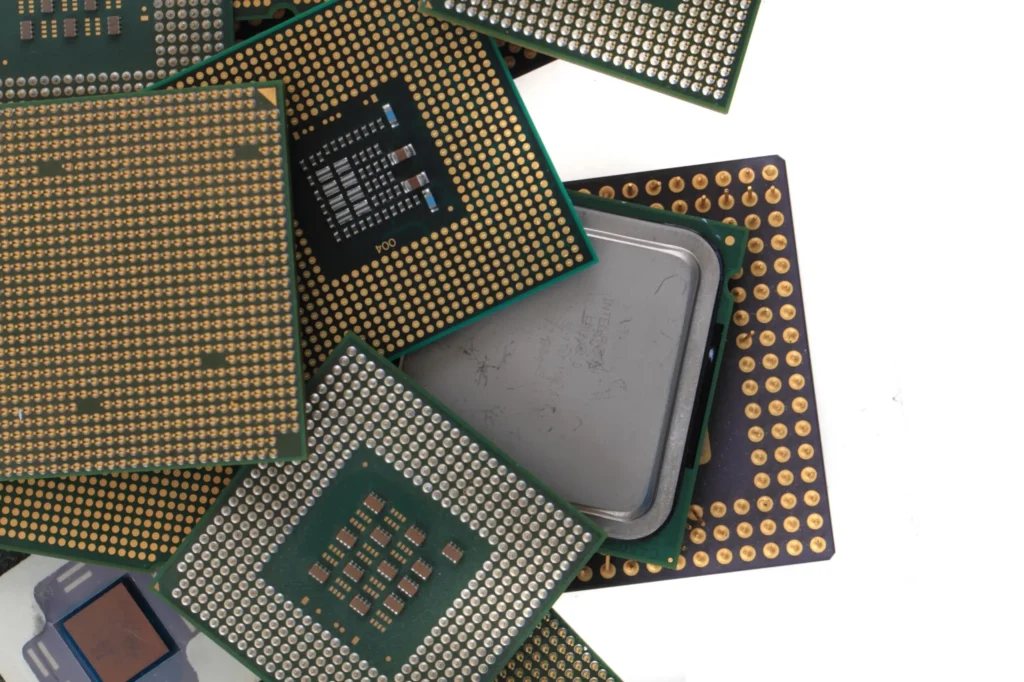

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

SMART CUT® Precision Diamond & CBN Wafering Blades are specially designed and selected to provide maximum blade life while maintaining desired cut quality and speed. They are manufactured using SMART CUT™ technology, ensuring consistent and reliable results for sample preparation and materials research. These blades offer exceptional performance and are available in various diamond concentrations, mesh sizes, bond hardness levels, and inside diameters.

SMART CUT® Diamond & CBN Wafering Blades are designed for laboratory-grade precision and are comparable to other leading brands like BUEHLER, STRUERS, and LECO. If you are not using these blades, you may be paying more without benefiting from their incredible performance and cost-effectiveness.

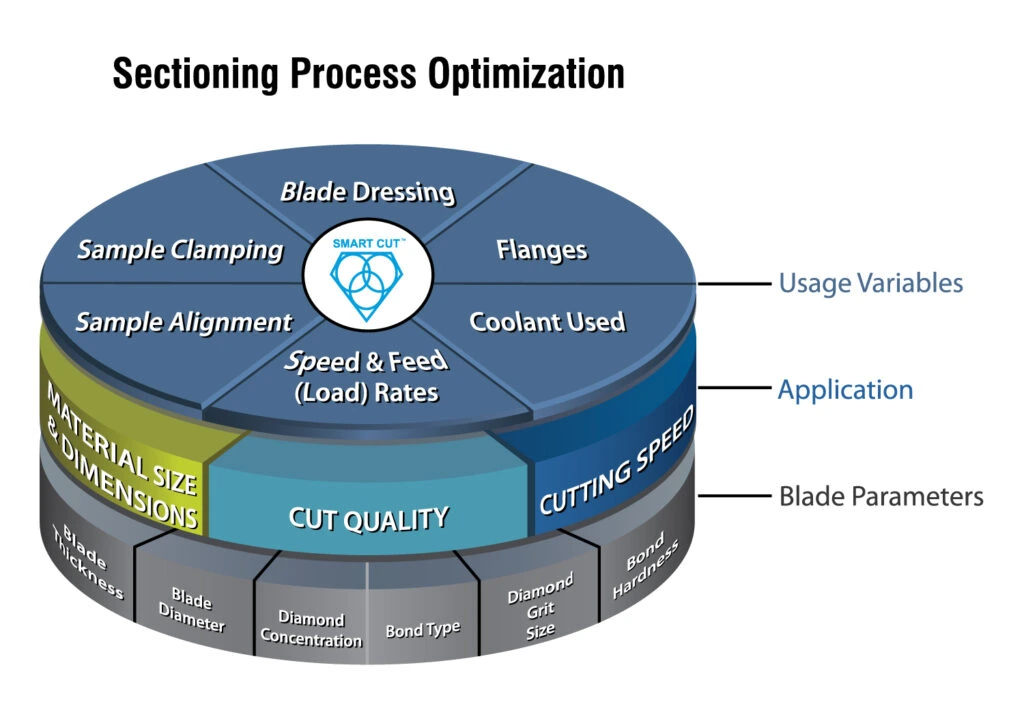

Several factors should be considered when choosing a diamond wafering blade, including diamond concentration, particle size (mesh), blade thickness, diameter, bond hardness, bond type (metal or resin), loads/feed rates, and blade speeds (RPMs). These factors depend on the material being cut and the desired cutting speed and quality.

Higher diamond concentration is recommended for cutting softer and more abrasive materials, while lower diamond concentration is suitable for cutting ultra-hard and brittle materials. The choice depends on the material you are working with and your desired cutting speed.

Diamond particle size (mesh) affects cutting speed, surface finish, chipping, and material microstructure damage. Coarse diamonds (larger mesh sizes) cut faster but may cause more damage, while finer mesh sizes are suitable for delicate materials.

Blade thickness affects material loss during sectioning. Thinner blades are ideal for precision cutting, especially when maintaining specific cutting planes is essential. Thicker blades are more robust and forgiving for less experienced operators.

Blade diameter should be chosen based on the material’s diameter and thickness. Smaller blades are more prone to bending, while larger blades are suitable for cutting larger and heavier samples at higher loads and speeds.

Bond hardness affects the ability of the bond matrix to hold diamonds. Softer bonds release diamond particles faster, leading to faster wear, while harder bonds result in slower cutting speeds. The choice depends on the material being cut.

Metal bonds offer durability, while resin bonds create less heat and provide a better surface finish. Metal bonds are suitable for a wide range of materials, while resin bonds are ideal for hard, delicate, or brittle materials.

Load/feed rates depend on the material’s hardness and brittleness. Harder materials are cut at higher loads and speeds, while more brittle materials are cut at lower loads and speeds. Factors like specimen shape and clamping also influence the load.

RPMs typically range from 50 to 6,000, with harder materials cut at higher speeds and more brittle materials at lower speeds. The material’s properties, shape, and clamping method determine the ideal RPM.

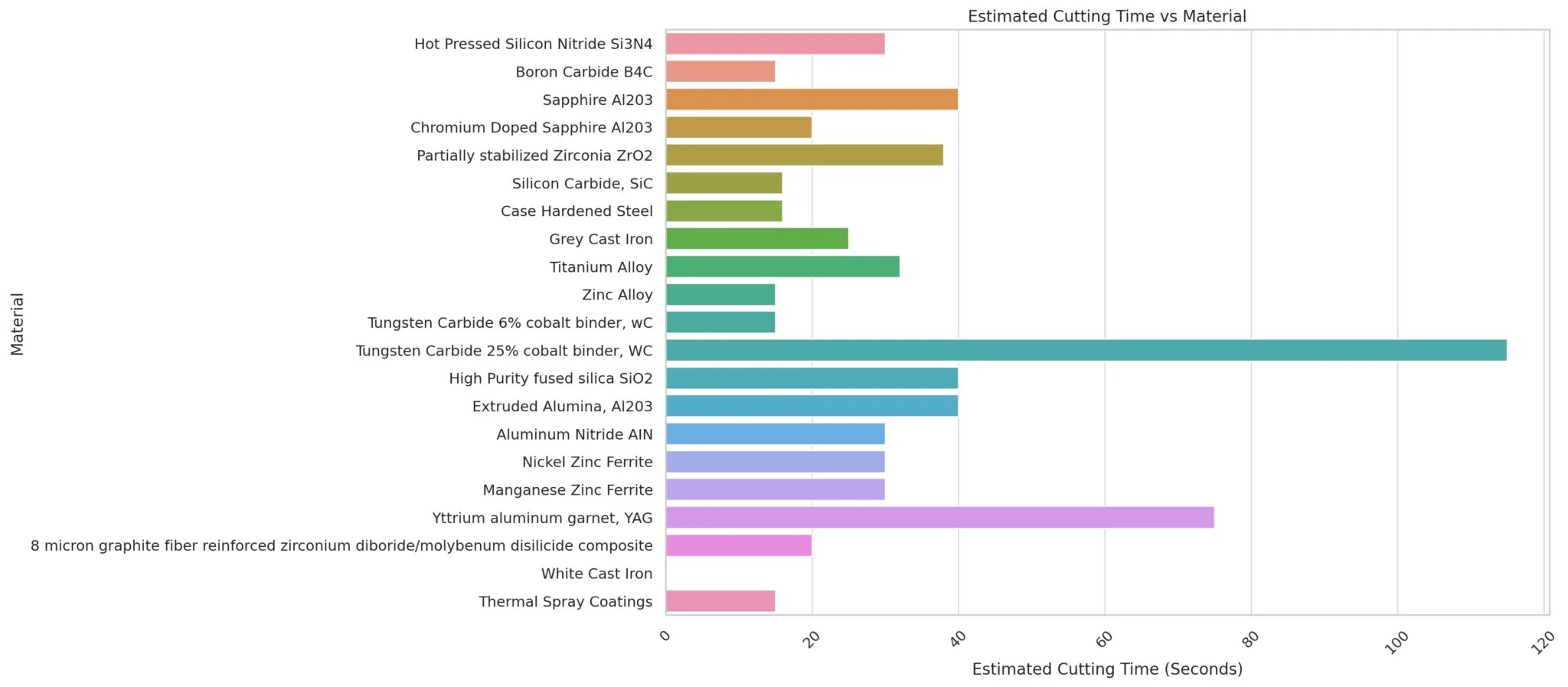

Cutting times depend on factors like material type, blade type, diamond concentration, speed, and load. To estimate cutting times accurately, refer to the provided examples or contact us for personalized guidance.

These blades can be used with plain water, synthetic coolant, or oil. They are easy to use and require minimal dressing, making them convenient for various cutting applications.

We provide an item number cross-reference chart for our SMART CUT® Diamond Wafering Blades, making it easy to match them with the blades you’ve used from other vendors. Contact us for immediate quotes and assistance.

Yes, we offer a wide range of sizes and specifications beyond those listed. Feel free to inquire about your specific requirements, and we will provide you with the available options.

Contact us directly to receive an immediate quote and further assistance with selecting the right blades for your needs. We are here to help you save money while achieving optimal results.

Yes, we offer a 100% quality guarantee, ensuring that you receive high-quality blades that meet your cutting requirements and expectations.

Visit our website for comprehensive information on these topics, including selection guides, usage recommendations, case studies, customer testimonials, and more. We are committed to helping you succeed in your cutting operations.

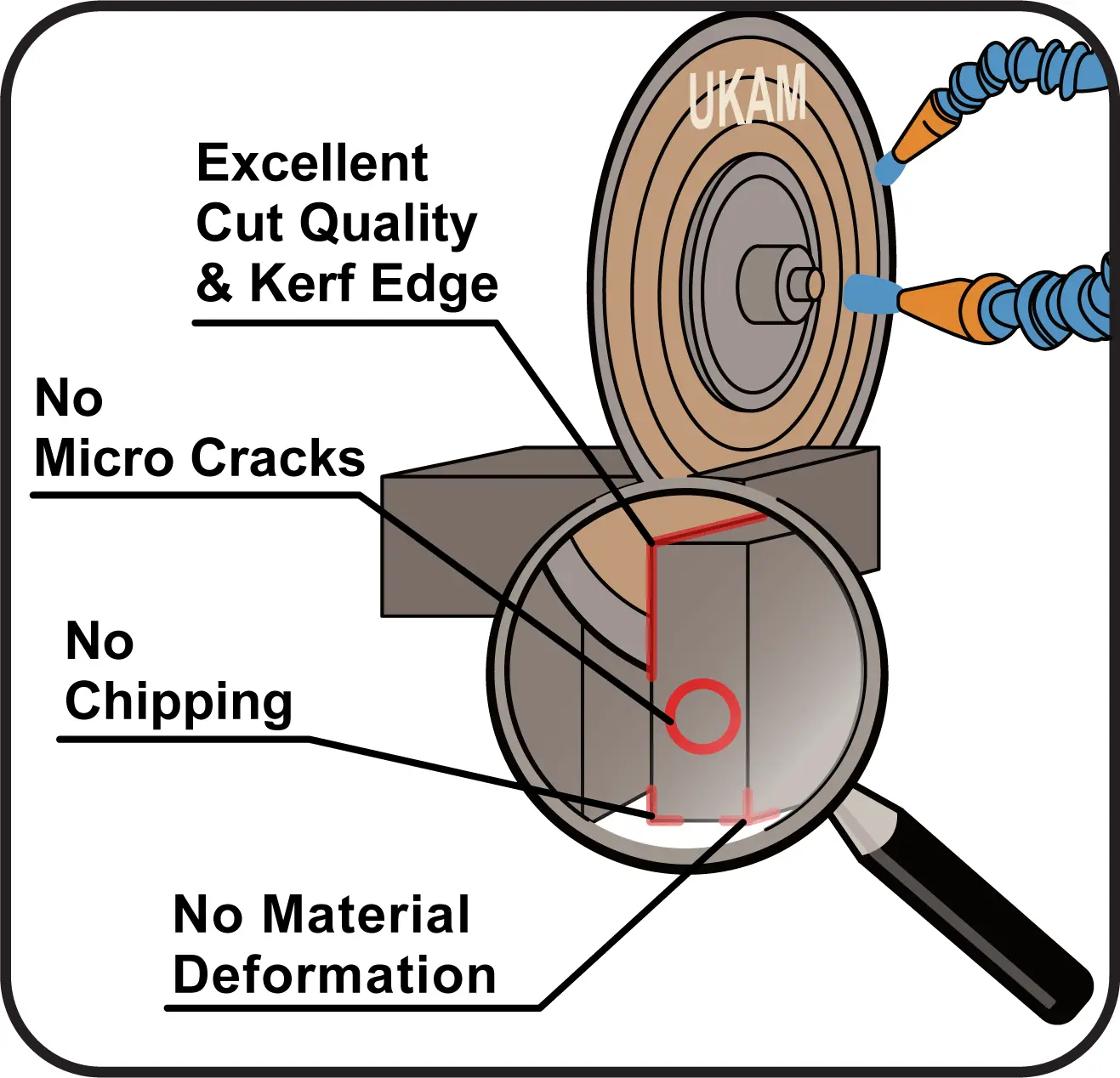

Diamond & CBN Wafering Blades are primarily used for precision cutting and sectioning of various materials in applications such as materials research, sample preparation, and materials analysis. They are designed to provide clean, precise cuts with minimal material deformation.

SMART CUT® Diamond & CBN Wafering Blades are known for their superior performance and longevity. They are designed using SMART CUT® technology, ensuring consistent results. These blades are often compared to well-known brands like BUEHLER, STRUERS, LECO, and many others. SMART CUT® blades offer comparable quality at significantly lower prices.

When choosing a wafering blade, you should consider factors such as the material you’re cutting, the material’s hardness, blade thickness, diamond concentration, mesh size, bond hardness, and the desired cutting speed. It’s essential to match the blade’s specifications to your specific application for optimal results.

Yes, these blades are versatile and suitable for cutting a wide range of materials, including metals, ceramics, glass, composites, and more. They offer excellent performance on various materials, making them a more universal choice.

Some advantages of using SMART CUT® blades include reducing or eliminating the need for additional post-cutting steps, preserving the material’s microstructure with minimal deformation, excellent performance even on materials with high metallic content, and longer blade life (up to 2.2 times longer). They are also competitively priced compared to other brand name blades.

Yes, SMART CUT® Diamond & CBN Wafering Blades can be used with various cutting fluids, including plain water, synthetic coolant, or oil, depending on your specific needs and preferences.

Yes, these blades are designed to work with both low and high-speed sectioning/wafering saws, making them adaptable to various equipment setups.

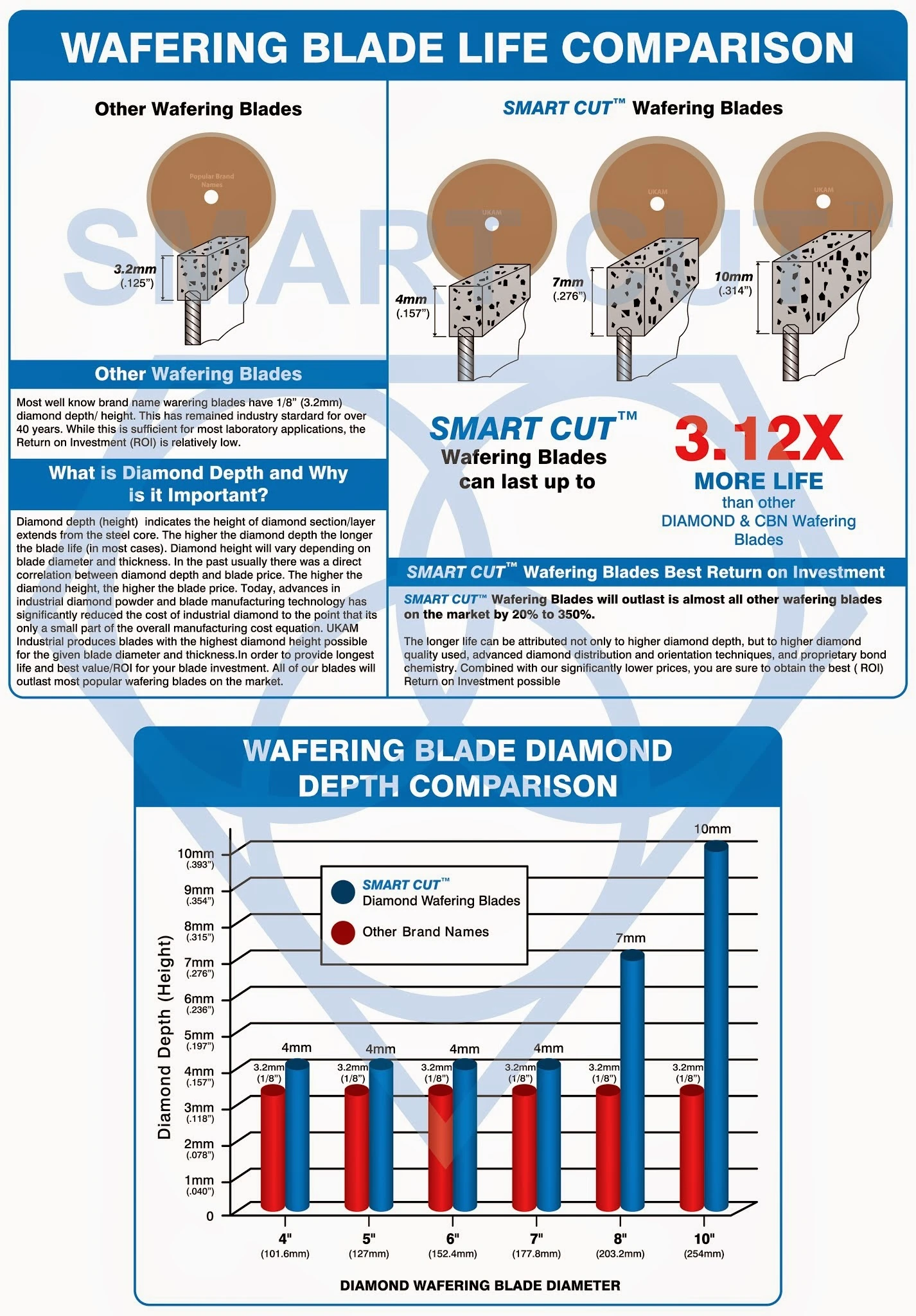

The diamond depth/height of 4mm (.157″) indicates the thickness of the diamond layer on the wafering blades. This specification is important because it affects the blade’s cutting performance and lifespan. A thicker diamond layer generally allows for longer blade life and more efficient cutting.

SMART CUT® Diamond & CBN Wafering Blades are versatile and can be used for wet cutting with cutting fluids like water, synthetic coolant, or oil. However, dry cutting without a lubricant is generally not recommended for extended blade life and performance.

SMART CUT® Diamond & CBN Wafering Blades are designed to be compatible with a wide range of cutting equipment, including both low and high-speed sectioning/wafering saws. They are versatile and can adapt to different machine setups.

These wafering blades are designed for minimal maintenance. However, it’s essential to clean and inspect the blades regularly to ensure they are free of debris and damage. If needed, they can be dressed or sharpened to maintain cutting performance.

SMART CUT® Diamond & CBN Wafering Blades are suitable for cutting a wide range of materials, including composite materials like carbon fiber-reinforced composites. They offer excellent performance on such materials.

Cutting speeds should be optimized based on the material being cut, blade specifications, and the specific equipment being used. The manufacturer can provide guidance on recommended cutting speeds for different materials and blade types.

Yes, SMART CUT® Diamond & CBN Wafering Blades are suitable for cutting extremely hard materials like sapphire and ceramics. They offer different blade specifications to match the hardness and characteristics of various materials, ensuring efficient cutting.

Yes, SMART CUT® Diamond & CBN Wafering Blades are specifically designed for precision cutting in research and laboratory applications. They are known for their exceptional performance and reliability in achieving precise cuts for materials analysis.

Selecting the right blade involves considering factors such as material hardness, thickness, shape, and other application-specific requirements. The manufacturer can provide expert guidance to help you choose the most suitable blade for your needs.

SMART CUT® blades offer several advantages, including comparable quality at significantly lower prices, longer blade life (up to 2.2 times more), no material deformation or smearing, and compatibility with a wide range of materials. They are a cost-effective alternative to conventional brand name blades.

Yes, SMART CUT® offers different series of wafering blades designed for various material types and applications. The choice of series depends on the material you plan to cut. Blades are designated in different series. The higher the Series Number the coarser the diamond, the lower the series the finer the diamond size. There are both low and high concentrations available for each blade family. If you have any questions please contact our technical support team to assist you in selecting the appropriate series based on your needs.

Yes, SMART CUT® Diamond & CBN Wafering Blades are known for their excellent performance, even on hard-to-machine materials. They can significantly reduce cutting times, making them suitable for efficient sectioning of challenging materials.

SMART CUT® Diamond & CBN Wafering Blades are designed to be compatible with various low and high-speed sectioning/wafering saws. The Standard arbor size is ½” (12.7mm). The arbor size can be changed to almost any thing you want usually same day for a small fee to fit any other equipment.

Yes, SMART CUT® Diamond & CBN Wafering Blades are suitable for cutting thermal spray coatings. They provide precise cutting capability even on challenging materials, such as thermal spray coatings.

Yes, we provide in our KNOWLEDGE CENTER a range of articles and resources on our website that cover topics such as selecting the right wafering blade, usage recommendations, case studies, customer testimonials, and more. These resources can be valuable for understanding blade selection and usage.

Yes, these blades are suitable for cutting composite materials with fine reinforcing media, including carbon composites. They are designed to provide precise cutting even on challenging materials like these.

Proper maintenance includes regular cleaning and inspection of the blades, as well as ensuring they are appropriately lubricated during use. Follow the manufacturer’s guidelines for blade care to optimize their lifespan.

Yes, these blades can be used for sectioning glass materials. Depending on the specific type of glass and your cutting requirements, you may find different series suitable. It’s advisable to consult with the manufacturer for personalized recommendations.

Safety is essential when using these blades. Always follow safety protocols, wear appropriate personal protective equipment (PPE), and ensure that the equipment is properly set up and maintained. The manufacturer may provide specific safety guidelines for their products.

Yes, these blades are designed to minimize material deformation, even when cutting brittle materials like ceramics. They are precision-engineered to preserve the true material microstructure.

SMART CUT® offers a range of arbor sizes, including 1/2″, 5/8″, 1″, 1-1/4″, and 32mm. Additionally, custom arbor sizes may be available upon request. Contact the manufacturer for specific arbor size requirements.

SMART CUT® Diamond & CBN Wafering Blades are known for their excellent performance on materials with high metallic content. They can provide precise cuts without smearing or material deformation. Follow the manufacturer’s guidelines for optimal results.

Yes, these blades can be used for cutting tough, gummy materials like lead alloys. The CBN – METACUT series is recommended for cutting iron, carbon steels, high alloy steels, cobalt alloys, nickel superalloys, and lead alloys. Consult with the manufacturer for specific recommendations based on your application.

Selecting the right wafering blade involves considering several factors, including the material you’re cutting, its hardness, size, and desired surface finish. You should also factor in your equipment’s capabilities and the specific cutting parameters you intend to use.

The material’s hardness, abrasiveness, and brittleness are crucial. Harder materials like ceramics may require a blade with a softer bond, while softer materials may benefit from a harder bond. Brittle materials may require a blade that minimizes chipping.

Metal bonds offer durability and long life, while resin bonds create less heat and are ideal for hard, delicate, or brittle materials. Select the bond type that best matches your material and desired cutting speed.

Diamond concentration affects cutting speed and blade life. Higher concentration is suitable for cutting softer materials, while lower concentration is better for harder materials. It’s a balance between speed and blade longevity.

Blade thickness affects material loss during cutting. Thinner blades are more precise but may bend or warp with heavy loads. Thicker blades are sturdier and withstand higher loads.

Blade diameter should match the size of the material you’re cutting. Larger blades are suitable for bigger samples and provide higher cutting speeds, while smaller blades are better for precision work on smaller specimens.

Bond hardness impacts diamond retention and cutting speed. Choose a bond hardness that complements your material’s hardness. Softer bonds work well for hard materials, while harder bonds are suitable for softer materials.

The material’s hardness, shape, and how it’s clamped affect the load/feed rate. Harder materials can handle higher loads, while brittle ones need lower loads to prevent damage.

Blade speeds depend on the material. Hard, dense materials like silicon carbide may require higher RPMs, while more brittle materials like silicon wafers need lower RPMs. Choose speeds that minimize material damage.

Yes, we offer customization options for wafering blades, including diamond concentration, bond hardness, and blade thickness. Contact us to inquire about custom solutions.

While some universal blades can work with various materials, it’s often best to have specialized blades for different materials. This ensures optimal performance, longer blade life, and superior cut quality.

Monitor the cutting process. If you notice excessive chipping, slow cutting speeds, or premature blade wear, it may indicate that you’re not using the right blade. Consult with us for recommendations.

while there are not specific standards related to diamond and cbn wafering blades for laboratory application. We follow the industry standard and cross reference our blades to most popular brand names such as BUEHLER, STRUERS, LECO & others

It’s generally best to use different blades for rough and precision cuts. Rough cuts may require blades with coarser diamond particles, while precision cuts benefit from finer diamonds and a softer bond.

Arbor size should match your equipment’s spindle. We offer the flexibility to customize arbor sizes to fit your equipment, we can machine the arbor size/inside diameter to anything you want usually same day.

Proper cooling methods, such as using coolants or lubricants, can help prevent blade overheating. Ensure your equipment is set up for effective cooling.

Yes, following the manufacturer’s guidelines for blade use, RPM, and maintenance is crucial to maximize blade life and maintain cut quality.

Used wafering blades should be disposed of according to local regulations and guidelines for handling hazardous materials. Consult your local waste management authorities for guidance.

Yes its possible, but there may be other blade specifications more suited for this application. Laboratory-grade wafering blades are designed for specific materials used in research and sample preparation. For industrial applications, consult with us to find a blade suited to your needs.

The diamond concentration depends on the hardness of the material you’re cutting. Softer materials typically require lower diamond concentration, while harder materials need higher concentrations. Consult our technical support for guidance.

Blade life depends on various factors, including material hardness, cutting speed, load, and blade specifications. Manufacturers may provide estimated blade life based on these factors, but actual results may vary.

sintered (metal bond) diamond wafering blades are not designed for dry cutting. Some Nickel bond wafering blades can be used dry (without coolant) in some cases and certain applications

Metal bond blades offer durability, while resin bond blades provide better surface finish. Consider the material and desired finish when deciding between the two bond type and rpm’s. Resin bond diamond wafering blades cannot be used on low speed cutting machines.

Yes, many diamond wafering blades are compatible with high-speed sectioning saws including sintered (metal bond), resin bond, and nickel bond. Ensure that the blade you choose matches the RPM range of your equipment.

You can optimize your cutting operation by following manufacturer recommendations for blade use, using appropriate coolants or lubricants, maintaining proper machine settings, and regularly inspecting the blade for wear.

If you encounter issues, first check if you’re using the right blade for the material and application. If problems persist, please our illustrated trouble shooting guide and consult our technical support team for troubleshooting and recommendations.

Store wafering blades in a clean, dry, and secure environment to prevent damage and contamination. Follow manufacturer guidelines for proper storage.

Switching between blades may require adjustments in cutting parameters and may result in different cutting characteristics. It’s essential to recalibrate your cutting process when changing blades.

Non-magnetic alloy cores help prevent magnetic materials from adhering to the blade, reducing the risk of contamination during cutting.

ACCESSORIES

Showing 1 – -1 of 16 results Showing all 16 results Showing the single result No results found

Sort by Name A – Z

Filters Sort results

Reset Apply

Image | Item No. | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

Color: 5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads into 5/8″-11″ female thread of diamond drill. Can be used with any other tool with 5/8″-11″ thread. | $26.72 | Max: Min: 1 Step: 1 | |||

Color: 5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads into 5/8″-11″ female thread of diamond drill. Can be used with any other tool with 5/8″-11″ thread. | $22.46 | Max: Min: 1 Step: 1 | |||

1 Gallon Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

1 Quart Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

5 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

55 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White For use on diamond tools 150 to 220 Grit Size. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $15.39 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $39.47 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $39.47 | Max: Min: 1 Step: 1 | |||

$154.87 | Max: Min: 1 Step: 1 | ||||

$154.87 | Max: Min: 1 Step: 1 | ||||

$235.00 | Max: Min: 1 Step: 1 |

USAGE RECOMENDATION

Diamond & CBN Wafering Blade Articles

02

Jun

Selecting the right parameters for your Precision & Ultra Thin Diamond Blade can be a very time consuming, trial & error frustrating process. The guide below has been designed to help you better understand…

02

Jun

How to Properly Use Precision Diamond & CBN Blades

The diamond blade itself is only a small factor in your cutting operation. Successful diamond sawing is both an art & science. Requiring proper use and understanding of the right: RPM’s, Coolants, Equipment, Dressing Devices, Accessories…

02

Jun

Precision & Ultra Thin Diamond Blade Guide

Diamond and CBN blades are available in an extensive array of varieties, each differing in bond types, manufacturing methods, and design specifics. Ultra Thin & High Precision Diamond Blades are particularly versatile, applicable…

02

Jun

Troubleshooting Diamond Sawing Problems

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in…

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations…

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which…

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens…

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning…

02

Jun

Wafering Blade Case Studies

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided…

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a…

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,…

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering…

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it’s crucial to consider key performance metrics and criteria. Different applications have varying goals, making it…

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it’s crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to…

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the…

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term “ROI” (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific…

09

Sep

Understanding Tradeoffs – Searching for Perfect Diamond Drill & Tool

Choosing the right diamond drill or tool can significantly impact efficiency, cost, and quality. However, this is not a simple and clear-cut process. Selecting the optimal drill or tool involves navigating a complex landscape of…

Examples of cutting times for Sectioning of Specific Materials 0.25″ (6.4mm) diameter rod. Using various cutting speeds.

|

Material |

Blade Type |

Diamond Concentration |

Speed (RPM’s) |

Load (grams) |

Estimated Cutting Time |

|---|---|---|---|---|---|

|

Hot Pressed Silicon Nitride Si3N4 |

Series 20LCU |

Low |

4,000 |

800 |

0:30 |

|

Boron Carbide B4C |

Series 20LCU |

Low |

3,500 |

700 |

0:15 |

|

Sapphire Al203 |

Series 15LCU |

Low |

1,500 |

300 |

0:40 |

|

Chromium Doped Sapphire Al203 |

Series 15LCU |

Low |

500 |

500 |

0:20 |

|

Partially stabilized Zirconia ZrO2 |

Series 15LCu |

Low |

2,500 |

500 |

0:38 |

|

Silicon Carbide, SiC |

Series 15LCU |

Low |

2,500 |

500 |

0:16 |

|

Case Hardened Steel |

Series 15HCU |

High |

2,500 |

500 |

0:16 |

|

Grey Cast Iron |

Series 15HCU |

High |

2,500 |

500 |

0:25 |

|

Titanium Alloy |

Series 15HCU |

High |

2,500 |

500 |

0:32 |

|

Zinc Alloy |

Series 15HCU |

High |

2,500 |

800 |

0:15 |

|

Tungsten Carbide 6% cobalt binder, wC |

Series 15HCU |

High |

4,500 |

900 |

0:15 |

|

Tungsten Carbide 25% cobalt binder, WC |

Series 15HCU |

High |

1,500 |

300 |

1:55 |

|

High Purity fused silica SiO2 |

Series 15HCU |

High |

2,500 |

500 |

0:40 |

|

Extruded Alumina, Al203 |

Series 15HCU |

High |

3,000 |

600 |

0:40 |

|

Aluminum Nitride AIN |

Series 15HCU |

High |

1,500 |

300 |

0:30 |

|

Nickel Zinc Ferrite |

Series 15HCU |

High |

1,500 |

300 |

0:30 |

|

Manganese Zinc Ferrite |

Series 15HCU |

High |

Content |

5,000 |

0:30 |

|

Yttrium aluminum garnet, YAG |

Series 15HCU |

High |

3,000 |

Content |

1:15 |

|

8 micron graphite fiber reinforced zirconium diboride/molybenum disilicide composite |

Series 15HCU |

Low |

2,500 |

300 |

0:20 |

|

White Cast Iron |

Series Metacut CBN |

High |

2,500 |

700 |

|

|

Thermal Spray Coatings |

Series 15HCU |

High |

3,000 |

700 |

Advantages

- Reduce & Eliminate additional steps often required after sectioning

- Preserve True Material Microstructure (no deformation)

- Excellent Performance, even on Materials with a High Metallic Content

- Works on larger variety of materials (More Universal)

- No Smearing / No Material Deformation

- Section Hard to machine materials 3 times faster

- Longer Life (Last 2.2 times longer)

- Priced 3 times less expensive than the leading / conventional Brand Name Wafering Blades

- Non Magnetic Alloy Core

- No Contamination

- Can be used with plain water, synthetic coolant, or oil

- Easy to Use / Minimal Dressing

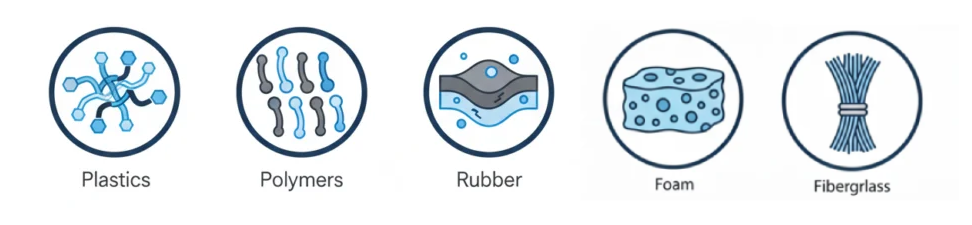

Series 30HCU

for soft & gummy materials. Use with plastics, polymers, rubber & etc.

Showing 1 – 3 of 3 results Showing all 3 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No | Diameter | Thickness | Arbor Size | BUEHLER NO | STRUERS NO | LECO NO. | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|

5"(127mm) | .030"(0.76mm) | 1/2"(12.7mm) | 11-4239 | $184.00 2 pcs - $179.00 ea 3pcs -$174.00 ea | Max: Min: 1 Step: 1 | |||||

8"(203mm) | .035"(0.9mm) | 1/2"(12.7mm) | 11-4242 | $214.00 2 pcs - $209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 | |||||

7"(178mm) | .030"(0.76mm) | 1/2"(12.7mm) | 11-4241 | $214.00 2 pcs - $209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 |

Series 20HCU

for aggressive general sectioning of metals (ferrous and non ferrous materials including titanium alloys).

Showing 1 – 4 of 4 results Showing all 4 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No | Diameter | Thickness | Arbor Size | BUEHLER NO | STRUERS NO | LECO NO. | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|

5"(127mm) | .020"(0.5mm) | 1/2"(12.7mm) | 11-4215 | 331CA 357CA 456CA | $184.00 2 pcs - $179.00 ea 3pcs -$174.00 ea | Max: Min: 1 Step: 1 | ||||

6"(152mm) | .020"(0.5mm) | 1/2"(12.7mm) | 356CA 370CA 457CA 459CA 45UCA | $194.00 2 pcs - $189.00 ea 3pcs -$184.00 ea | Max: Min: 1 Step: 1 | |||||

7"(178mm) | .025"(0.6mm) | 1/2"(12.7mm) | 11-4237 | $214.00 2 pcs - $209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 | |||||

8"(203mm) | .025"(0.6mm) | 1/2"(12.7mm) | 11-4238 | 655CA 657CA 659CA | $214.00 2 pcs - $209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 |

Series 15HCU

For general use with ferrous and non ferrous alloys, copper, aluminum, metal matrix, composites, PC boards, thermal spray coatings, and titanium alloys

Showing 1 – 7 of 7 results Showing all 7 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No | Diameter | Thickness | Arbor Size | BUEHLER NO | STRUERS NO | LECO NO. | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|

3"(76mm) | .015"(0.35mm) | 1/2"(12.7mm) | 100CA | $159.00 2 pcs - $154.00 ea 3pcs-$149.00 ea | Max: Min: 1 Step: 1 | |||||

4"(101.1mm ) | .012" (0.3mm) | 1/2"(12.7mm) | 11-4244 | 230CA 40000043 M0D10 | $159.00 2 pcs - $154.00 ea 3pcs-$149.00 ea | Max: Min: 1 Step: 1 | ||||

3"(76mm) | .006"(0.15mm) | 1/2"(12.7mm) | 11-10066 11-4243 | 121CA 40000041 M0D08 | $165.00 2 pcs - $160.00 ea 3pcs-$155.00 ea | Max: Min: 1 Step: 1 | ||||

5"(127mm) | .015"(0.4mm) | 1/2"(12.7mm) | 11-4245 | 330CA 355CA 357CA 40000038 M0D13 | $184.00 2 pcs - $179.00 ea 3pcs -$174.00 ea | Max: Min: 1 Step: 1 | ||||

6" (152mm) | .020" (0.5mm) | 1/2"(12.7mm) | 11-4246 | 4000054 430CA 459CA M0D15 | $194.00 2pcs -$189.00 ea 3pcs -$184.00 ea | Max: Min: 1 Step: 1 | ||||

7" (178mm) | .025" (0.6mm) | 1/2"(12.7mm) | 11-4247 | 40000046 M4D18 | $214.00 2pcs -$209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 | ||||

8"(203mm) | .035"(0.9mm) | 1/2"(12.7mm) | 11-4248 | 40000084 657CA M020 | $214.00 2 pcs - $209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 |

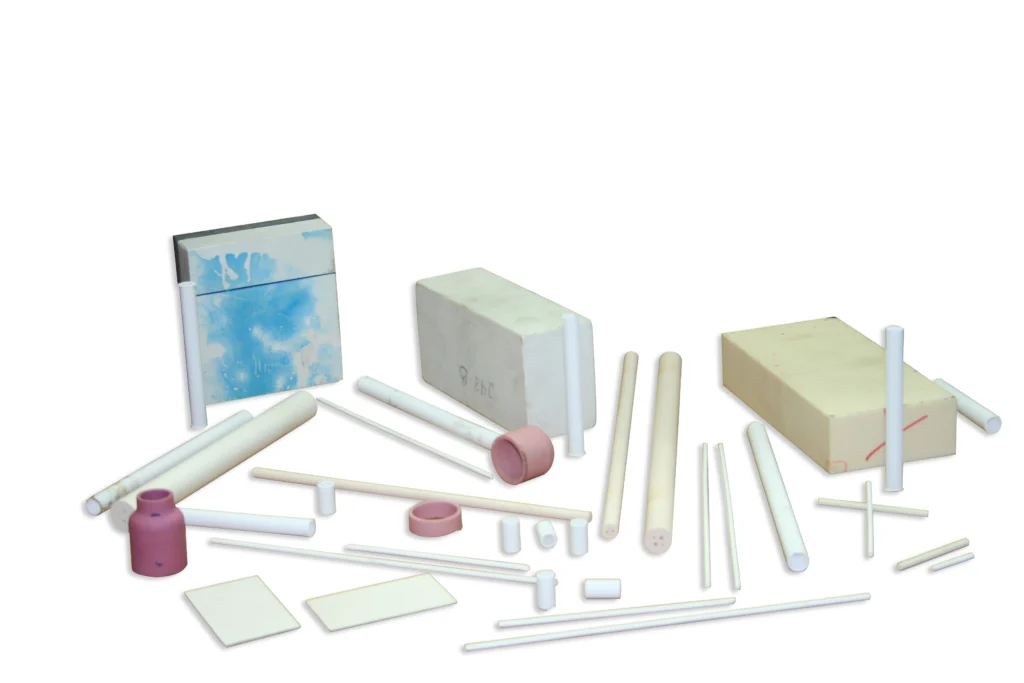

Series 20LCU

for use with hard/tough materials, structural ceramics, boron carbide, boron nitride, and silicon carbide

Showing 1 – 4 of 4 results Showing all 4 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No | Diameter | Thickness | Arbor Size | BUEHLER NO | STRUERS NO | LECO NO. | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|

4"(101.1mm) | .012"(0.3mm) | 1/2"(12.7mm) | 452CA | $159.00 2 pcs - $154.00 ea 3pcs-$149.00 ea | Max: Min: 1 Step: 1 | |||||

5" (127mm) | .020" (0.5mm) | 1/2"(12.7mm) | 11-4225 | 352CA | $184.00 2 pcs - $179.00 ea 3pcs -$174.00 ea | Max: Min: 1 Step: 1 | ||||

7"(178mm) | .025"(0.6mm) | 1/2"(12.7mm) | 11-4227 | $214.00 2pcs -$209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 | |||||

8"(203mm) | .035"(0.9mm) | 1/2"(12.7mm) | 11-4228 | 652CA | $214.00 2 pcs - $209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 |

Series 15LCU

for use with hard / brittle materials such as Glass, Al203, Zr203, Concrete, & many others

Showing 1 – 7 of 7 results Showing all 7 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No | Diameter | Thickness | Arbor Size | BUEHLER NO | STRUERS NO | LECO NO. | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|

3"(76mm) | .015"(0.35mm) | 1/2"(12.7mm) | 100CA | $159.00 2 pcs - $154.00 ea 3 pcs - $149.00 ea | Max: Min: 1 Step: 1 | |||||

4"(101.1mm) | .012"(0.3mm) | 1/2"(12.7mm) | 11-4254 | 230CA 40000070 M1D10 | 801-137 | $159.00 2 pcs - $154.00 ea 3 pcs - $149.00 ea | Max: Min: 1 Step: 1 | |||

3"(76mm) | .006"(0.15mm) | 1/2"(12.7mm) | 11-10067 | 40000069 M1D08 | $165.00 2 pcs - $160.00 ea 3 pcs - $155.00 ea | Max: Min: 1 Step: 1 | ||||

5"(127mm) | .015"(0.4mm) | 1/2"(12.7mm) | 11-4255 | 330CA 40000071 M1D13 | 802-439 | $184.00 2 pcs - $179.00 ea 3pcs -$174.00 ea | Max: Min: 1 Step: 1 | |||

6"(152mm) | .020"(0.5mm) | 1/2"(12.7mm) | 11-4276 | 40000068 430CA M1D15 | $194.00 2 pcs - $189.00 ea 3 pcs - $184.00 ea | Max: Min: 1 Step: 1 | ||||

7"(178mm) | .025"(0.6mm) | 1/2"(12.7mm) | 11-4277 | $214.00 2 pcs - $209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 | |||||

8" (203mm) | .035" (0.9mm) | 1/2"(12.7mm) | 11-4279 | 40000072 M1D20 | $214.00 2 pcs - $209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 |

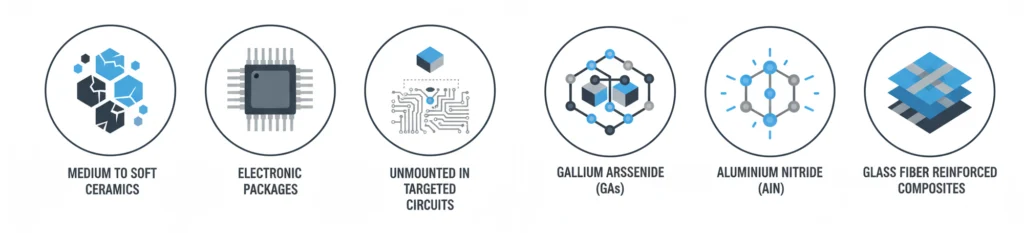

Series 10LCU

for use with medium to soft ceramics, electronic packages, unmounted in targeted circuits, GaAs, AIN and glass fiber reinforced composites

Showing 1 – 5 of 5 results Showing all 5 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No | Diameter | Thickness | Arbor Size | BUEHLER NO | STRUERS NO | LECO NO. | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|

3"(76mm) | .015"(0.35mm) | 1/2"(12.7mm) | $159.00 2 pcs - $154.00 ea 3 pcs - $149.00 ea | Max: Min: 1 Step: 1 | ||||||

3"(76mm) | .006"(0.15mm) | 1/2"(12.7mm) | 11-10068 11-4283 | $165.00 2 pcs - $160.00 ea 3 pcs - $155.00 ea | Max: Min: 1 Step: 1 | |||||

5"(127mm) | .015"(0.4mm) | 1/2"(12.7mm) | 11-4285 | $184.00 2 pcs - $179.00 ea 3pcs -$174.00 ea | Max: Min: 1 Step: 1 | |||||

7"(178mm) | .025"(0.6mm) | 1/2"(12.7mm) | 11-4287 | $214.00 2 pcs - $209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 | |||||

8" (203mm) | .035" (0.9mm) | 1/2"(12.7mm) | 11-4288 | $214.00 2 pcs - $209.00 ea 3pcs -$204.00 ea | Max: Min: 1 Step: 1 |

Series 5LCU

for use with softfriable ceramics, electronic packages, unmounted integrated circuits, composites with fine reinforcing media, CaF2, MgF2, and carbon composites

Showing 1 – 2 of 2 results Showing all 2 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No | Diameter | Thickness | Arbor Size | BUEHLER NO | STRUERS NO | LECO NO. | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|

3"(76mm) | .006"(0.15mm) | 1/2"(12.7mm) | 11-4288 11-4298 | $165.00 2 pcs - $160.00 ea 3 pcs - $155.00 ea | Max: Min: 1 Step: 1 | |||||

5"(127mm) | .015"(0.4mm) | 1/2"(12.7mm) | 11-4295 | $184.00 2 pcs - $179.00 ea 3pcs -$174.00 ea | Max: Min: 1 Step: 1 |

23-4870ME(3053001), 23-4872ME(3083204), 23-4871ME(3073002), 23-4873ME(3052008), 23-4874ME(3062014), 23-4875ME(3072510), 23-4876ME(3083220), 23-4877ME(3031204), 23-4878ME(3041201), 23-5159ME(3030605), 23-4879ME(3051502), 23-4880ME(3062006), 23-4881ME(3072501), 23-4882ME(3083202), 23-4883ME(3041207), 23-4884ME(3052010), 23-4885ME(3072509), 23-4886ME(3083218), 23-4887ME(3031001), 23-4888ME(3041202), 24-4887ME(3030606), 23-4889ME(3051504), 23-4890ME(3062011), 23-4891ME(3072502), 23-4892ME(3083219), 23-4891ME(3031201), 23-5160ME(3030604), 23-4892ME(3051506), 23-4893ME(3072503), 23-4894ME(3083217), 23-4895ME(3031202), 24-4895ME(3030608), 23-4896ME(3051507)

SMART CUT® CBN Wafering Blades

For iron, carbon steels, high alloy steels, cobalt alloys, nickel super alloys, and lead alloys. CBN is recommended for cutting had metals, specially iron and steel. Since carbon in steel reacts with carbon in diamond, quickly dulling the diamond crystal and slowing the material removal. CBN blades provide significantly reduced cutting times for tough, gummy materials, such as lead and titanium. However, CBN are not recommended for ceramics and other non metallic materials. These blades will provide precise cutting capability on difficult to cut samples/materials. These CBN blades will significantly reduce your cutting time on ferrous materials compared to convention al diamond wafering blades. Standard arbor size inside diameter is ½” (12.7mm) (* we can modify arbor size of any blade to anything you want same day for a small addition al fee, if needed)

Showing 1 – 6 of 6 results Showing all 6 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No | Diameter | Thickness | Arbor Size | BUEHLER NO | STRUERS NO | LECO NO. | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|

4"(101.1mm) | .012"(0.3mm) | 1/2"(12.7mm) | 11-4264 11-5264 | 235CA | $174.00 2 pcs - $169.00 ea 3pcs -$164.00 ea | Max: Min: 1 Step: 1 | ||||

3"(76mm) | .006"(0.15mm) | 1/2"(12.7mm) | 11-10070 11-10071 11-4263 | $180.00 2pcs -$175.00 ea 3pcs-$170.00 ea | Max: Min: 1 Step: 1 | |||||

5"(127mm) | .015"(0.4mm) | 1/2"(12.7mm) | 11-4265 11-5265 | 355CA | $199.00 2 pcs - $194.00 ea 3pcs -$189.00 ea | Max: Min: 1 Step: 1 | ||||

6"(152mm) | .020"(0.5mm) | 1/2"(12.7mm) | 11-4266 11-5266 | 455CA | $209.00 2 pcs - $204.00 ea 3pcs -$199.00 ea | Max: Min: 1 Step: 1 | ||||

8"(203mm) | .035"(0.9mm) | 1/2"(12.7mm) | 11-4268 11-5268 | 655CA | $240.00 2 pcs - $235.00 ea 3pcs -$230.00 ea | Max: Min: 1 Step: 1 | ||||

7"(178mm) | .025"(0.6mm) | 1/2"(12.7mm) | 11-4267 11-5267 | $245.00 2 pcs - $240.00 ea 3pcs -$235.00 ea | Max: Min: 1 Step: 1 |

23-4898ME (3041205), 23-016CBN(3030601), 23-4899ME(3051501), 23-4900ME(3062007), 23-4902ME(3083208), 23-4901ME (3072504)

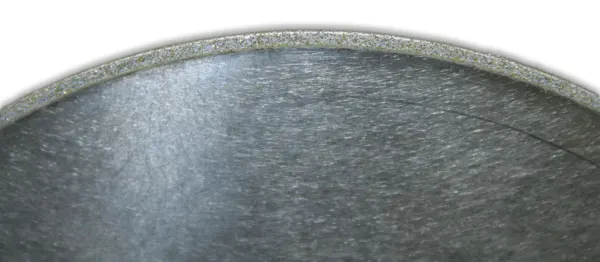

About Sintered (Metal Bond)

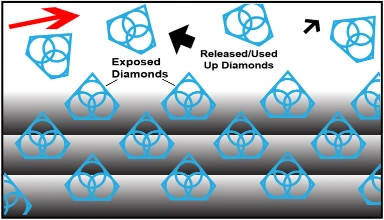

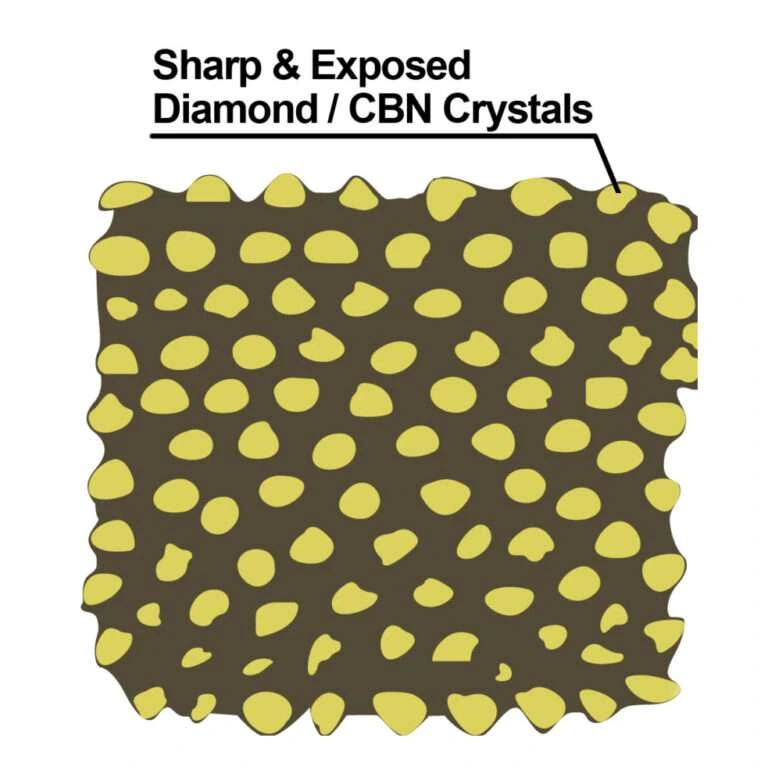

Sintered (Metal Bond) diamond tools have multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. Metal bonded diamond tools are “impregnated” with diamonds. This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance possible on any materials such as sapphire, advanced ceramics, optics, glass, granite, tile and etc. The metal bond surrounding the diamonds must wear away to continuously keep re-exposing the diamonds for the diamond tool to continue cutting. Sintered (metal bonded) diamond tools are recommended for machining hard materials from 45 to 75 on rockwell scale (5 to 9.5 on mohe’s scale of hardness).

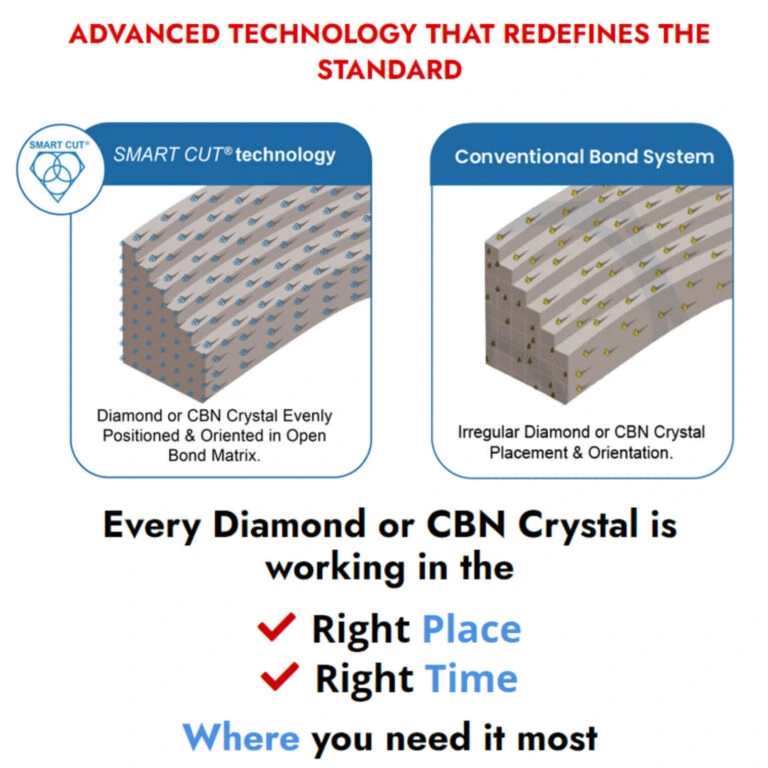

How SMART CUT® Bond Works?

Step 1

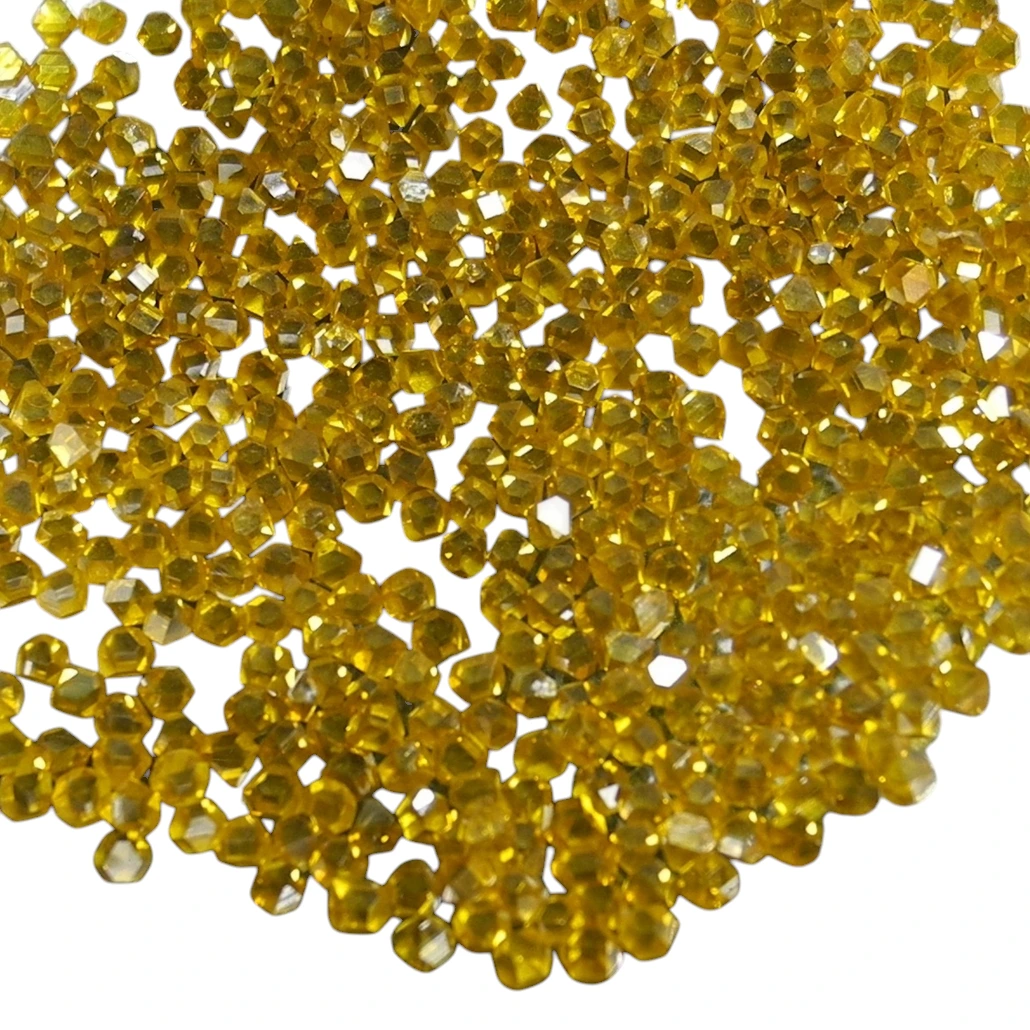

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

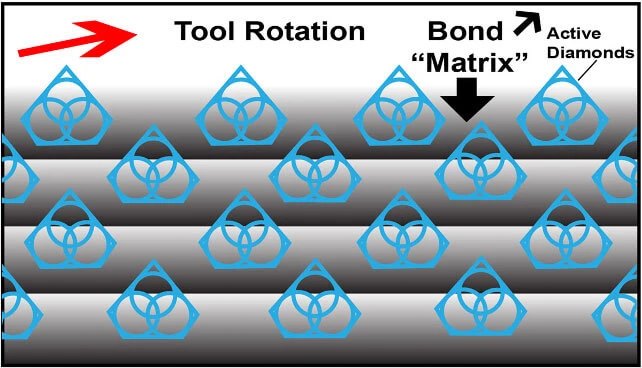

Step 2

Diamonds or CBN Crystals

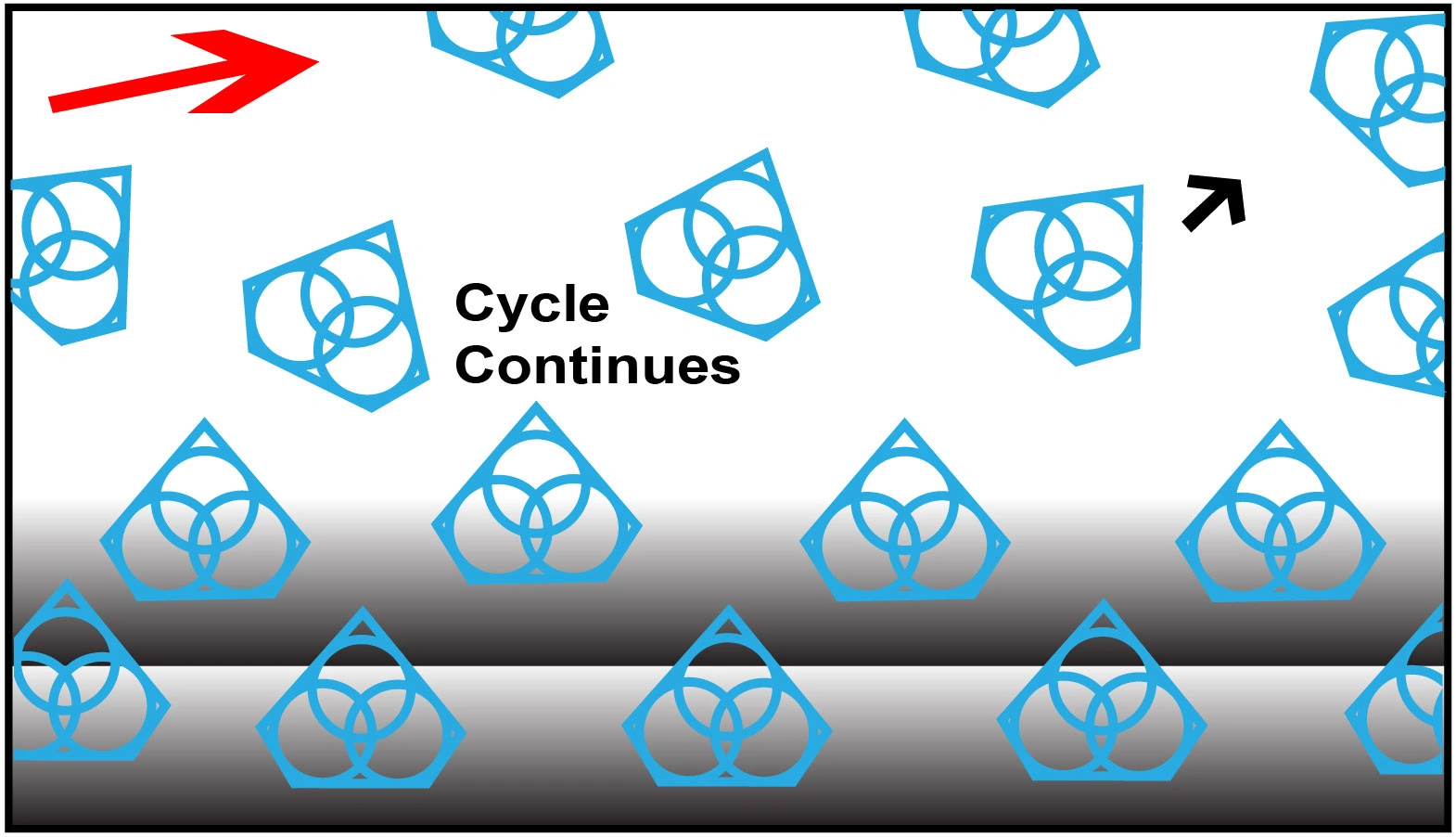

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

SMART CUT® Difference

How SMART CUT® Diamond & CBN Wafering Blades are Different in comparison to other Wafering blades.

No Glazing

Diamond & CBN Wafering Blades with SMART CUT® technology require minimum dressing, the bond renews itself.

More Consistent Performance

Diamond & CBN Wafering Blades are produced using only the highest quality raw materials are used in manufacturing process. Utilizing world class quality control, inspection, and measurement equipment. Highly Experienced Engineers constantly monitor and control all material input & output at all stages of manufacturing process. Insuring product consistency for use in demanding & sensitive applications SMART CUT® DIAMOND & CBN wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing.

Faster Cutting Action

Diamond & CBN Wafering Blades made utilizing SMART CUT® technology are much more aggressive than your conventional tools. They can cut faster, while still leaving behind a smooth finish free of material deformation.

Longer Life

In most cases Wafering Blades manufactured utilizing SMART CUT® technology, will outlast other conventional material (sintered), resin, and nickel bonded diamond & CBN Wafering Blades. SMART CUT® diamond & CBN Wafering Blades are more sturdy than Wafering Blades manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

Best Performance & Value on the Market

SMART CUT® Diamond & CBN Wafering Blades are the best investment you can make! Although we may not always be the lowest cost solution provider. Our Diamond & CBN Wafering Blades can provide the best ROI. Designed for users that understand and appreciate quality. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

Manufactured Using The Highest Quality Raw Materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

Why Choose SMART CUT® Diamond & CBN Wafering Blades?

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Diamond Wafering Blade

Selection Variables

Diamond Concentration

Diamond Concentration – Diamond Concentration is still a factor in determining the life and cutting speed of your Diamond Sectioning/Wafering Blade. Higher diamond concentration is recommended and usually used for cutting softer and more abrasive types of materials. However, the trade off is significantly slower cutting speed. Low diamond concentration is recommended and widely used for cutting ultra hard and brittle materials.

Low Diamond Concentration - typically low concentration wafering blades should be for cutting ultra hard and brittle materials such as ceramics and glass. In Low Concentration Wafering Blades, diamond works by fracture process. Pressure on each diamond crystal/particle is higher which provides enough stress to chip off small flakes in the cut.

High Diamond Concentration - High concentration diamond wafering blades are recommended for cutting metals, plastics and polymers. In this application, materials cut by a plowing mechanism. In this applications diamond plough through the material, work hardened strips of materials become brittle and break off. The greater number of diamond by volume, the quicker the cutting action will be. Increasing the number of diamond s also lowers the per unit force. For metals where it is possible to induce deep deformation layers, a lower per unit force is desirable to reduce the deformation during the cut.

Blade Thickness

Wafering blade thickness typically ranges from .006” to .040” (1mm). Thinner and thicker wafering blade are available, frequently from stock upon request. Kef thickness typically increases with blade diameter (in proportion to diameter of the blade). Kerf is the amount of material removed from the material/sample due to the thickness of blade passing though the material/sample. Blade thickness is important for users requiring most minimal amount of material loss during sectioning

For example if the user requires precision position of the cutting plane relative to the detail on the sample (IC circuit for example), a thinner and smaller diameter blade would be best for this application. Blades ranging from 3” to 5” (75mm to 125mm) in diameter and thickness .006” to .015” (0.2mm to 0.4mm) would be bet suited for this purpose. There are large variety of factors that will contribute to optimal blade thickness for your material/application Including your desired cutting speed, load/feed rate, material diameter, thickness, hardness, density, and shape. As well as skill & experience of the operator. Thicker wafering blades are more stiff and can whistand higher loads/feed rates. Another advantage of thicker kerf blades is they are more forgiving to operator error and abuse. Thicker kerf blade are recommended for use in environment where large number of individuals will be sharing and using same equipment. Perfect for less experienced and novice saw operators, such as in University laboratory.

.

Diamond Particle/Grit size

Diamond Mesh Size plays a major role in determining your cutting speed, cut quality/surface finish, level of chipping you will obtain, and material microstructure damage you will obtain. Diamond Mesh size does have considerable effect on cutting speed. Coarse Diamonds are larger than finer diamonds and will cut faster. However, the tradeoff is increase in material micro damage. If you are cutting fragile, more delicate materials then finer mesh size diamond wafering blades are recommended.

Bond Type

Metal bonding offers long life and durability, while resin bonding creates less heat, provides better surface finish and is well suited for cutting hard, delicate or brittle materials.

Blade Outside Diameter

typically wafering blade diameters range form 3” (75mm) to 8” (200mm). Wafering blade diameter should be selected based on material diameter and thickness being cut. Smaller diameter wafering blades are thinner than the larger diameter blades and are more prone to bending and warping. Although large diameter blades are thicker, they are typically used for cutting larger and heavier samples at higher loads and speeds than smaller blades

Feed Rates

load/feed rate applied to wafering blades typically vary from 10-1000 grams. Generally, harder specimens are cut at higher loads and speeds (e.g. ceramics and minerals) and more brittle specimens are cut at lower loads and speeds (e.g. electronic silicon substrates). The Speeds/RPM’s you are using, shape/geometry of the specimen, and how the specimen is being clamped/hold in place will affect the load that can be used for your application.

Bond Hardness

Ability of the bond matrix to hold diamonds. As the hardness of the bond is increased, its diamond retention capabilities increase as well. However the trade off is slower cutting speed. Life of the diamond blade is usually increased with hardness of its bond matrix. Bonds are designated on their scale of hardness from Soft, Medium, and Hard. There are dozens of variations and classification schemes based on bond degree of hardness or softness.

Using diamond blades with optimum bond hardness for your application is important to successful precision diamond sawing operation. Bond matrix that is too soft for the material being cut will release diamond particles faster than needed, resulting in faster wear and shorter diamond blade life. On other hand bond matrix that is too hard will result in much slower cutting speeds and require constant dressing to expose the next diamond layer. As rule of thumb, harder materials such as sapphire and alumina generally require a softer bond. Whereas softer and more brittle materials require a harder bond.

Blade Speeds/RPM’s

Most wafering blades are used between 50 to 6,000 RPM’s Typically harder and more denser materials such as Silicon Carbide, are cut at higher RPM’s/speeds Where more brittle materials such as silicon wafers and gallium arsenide are cutting at lower RPM’s. Low Speed saws RPM’s are typically limited from 0 to 600 RPM’s. Where high speed saws offer much large variety of cutting speeds from 0 to 6,000 RPM’s.

Why Work With Us?

Read More

Save Money Save up to 650%

We produce diamond consumables for some of the leading world OEM manufacturers. We offer Manufacturers Direct Prices

COMPARE TO: BUEHLER , STRUERS , LECO & MANY OTHERS

Large Inventory & Custom Manufacturing

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

Umatched Technical Support

WE ARE A PARTNER IN YOUR SUCCESS

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Superior Quality & Consistency

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

EXPECT MORE FROM YOUR TOOLS

Comprehensive Source Of Information For Sample Preparation

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

Advanced Technology

AMERICAN MANUFACTURER

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Experience Makes All The Differences

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years

Let Us Help You

- Obtain More Consistent Results

- Save Time & Money

- improve Surface Finish

- Preserve True Material Microstructure

- Improve Consumable Life & Overall Performance

- Reduce & eliminate Material Deformation

Related Products

SMART CUT® CBN WAFERING BLADES SINTERED (METAL BOND)

SMART CUT® Ultra Thin Abrasive Cut off Blades

SMART CUT Series Ultra Thin Abrasive Blades are designed to provide high quality sectioning results with no burning and minimal surface deformation. This can reduce the amount of grinding & polishing required later in the preparation process. Our blades are Formulated for fast sectioning with minimum kerf loss. They Provide for cool cutting action & Minimize the structural damage to the sample/material.

The thin kerf is designed to save money by reducing kerf loss. This is especially important when cutting very expensive materials, or when kerf loss represents a significant portion of the original material cost.

Used On: All Low & High Speed Wafering Saws, Sectioning Saws, Such as Buehler, Struers, Leco, & many others.

SMART CUT® Series 3000R Resin Bond, Diamond Cut Off Blade

Resin Bond Diamond Cut off blades (Fine Size Diamond) for use on manual tile saws

SMART CUT® Series 3000R are the highest quality & most commonly used Resin Bond Diamond Cut off Blades / Cut Off Wheels available today. Finer Diamond Grit Size, and Slightly Higher Diamond Content then the SMART CUT Series 2000R blades. They are used for cutting very thin wall tubing, more fragile material, that need best surface finish possible to achieve. Cutting speed would be slower then the 2000R series. These blades cut more slowly due to their finer grit size, which provides less aggressive material removal. They are better suited for precision tasks where cut quality is prioritized over speed. The finer grit results in a much smoother surface finish with minimal chipping, making them ideal when a high-quality, clean cut is needed, especially for delicate materials The resin bond diamond cut off blades / cut off wheels excel in delivering superior cut quality compared to other diamond cutting blade, making them ideal for applications where cut quality and surface finish is highly important. They are designed to operate at higher speeds to minimize heat generation and improve surface finishes.SMART CUT® Series 400 Wafering Blade, Resin Bond

Resin Bond Diamond Wafering Blades for use on Precision & Laboratory type Cut off Saws

SMART CUT® Series 400 are Designed for Precision, Chip Free cutting of wide variety of materials These are very thin kerf blades and are very delicate. Must be used on high precision specialized laboratory cutting saws (not tile saws, trim saws, etc) The diamond section can be easily broken if the material moves while cutting, blade is dropped, material is feed to fast into the blade, material is not fed consistently straight into the blade (shifts position) etc. Diamond Size is Medium providing faster cutting speed, while still providing surface quality unmatched by 95% of other blades.SMART CUT 105N Diamond, Nickel Bond Wafering Blades INTERRUPTED RIM

SMART CUT™ Series 105N more freer cutting & aggressive than continuous rim nickel bond wafering blades. Best Suited for cutting larger variety of micro-electronics packages, pcb boards, plastics, composites, soft and precious metals, fish and human bones, graphite, GRP, FR4. Core steel with memory. Always snaps back to its original shape no matter how much bent.

Standard arbor size inside diameter is ½” (12.7mm) (* we can modify arbor size of any blade to anything you want same day for a small additional fee, if needed)

SMART CUT® Series 100N Wafering Blade, Nickel Bond

NICKEL BOND, DIAMOND CONTINUOUS RIM

SMART CUT® Series 100N will provide finer cut quality than interrupted rim nickel bond wafering blades. Best suited for cutting soft and fragile crystals, silicon wafers & substrates, fiberglass, glass fibers. made with stainless steel core Standard arbor size inside diameter is ½” (12.7mm) (* we can modify arbor size of any blade to anything you want same day for a small additional fee, if needed) Nickel Bond Diamond Cut off blades Blades usually have a single layer of diamonds, held by a tough durable nickel alloy. diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.Diamond, Nickel Bond Cut Off Blades for Laboratory & Other Saws

SMART CUT® Fully Sintered (Metal Bond) Diamond & CBN, Wafering Blades

SMART CUT® Fully Sintered (Metal Bond) diamond wafering blades are fully sintered from OD to ID of the blade. Meaning they have diamonds completely impregnated through the blade. Unlike standard diamond & cbn wafering blades with steel core and diamond section. Instead of having a steel core and small diamond bond edge (usually 1/8"/3.2mm). The diamond edge is all the way through the blade, from its Outside Diameter to Inside Diameter of the blade. You can use until the entire Outside Diameter of the blade is consumed.

Recently Viewed Products

ARE YOU USING RIGHT WAFERING BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT WAFERING BLADES?

Knowledge Center

02

Jun

Select right Diamond Blade for your application

Selecting the right parameters for your Precision & Ultra Thin Diamond Blade can be a very time consuming, trial & error frustrating process. The guide below has been designed to help you better understand...

02

Jun

How to Properly Use Precision Diamond & CBN Blades

The diamond blade itself is only a small factor in your cutting operation. Successful diamond sawing is both an art & science. Requiring proper use and understanding of the right: RPM's, Coolants, Equipment, Dressing Devices, Accessories...

02

Jun

Precision & Ultra Thin Diamond Blade Guide

Diamond and CBN blades are available in an extensive array of varieties, each differing in bond types, manufacturing methods, and design specifics. Ultra Thin & High Precision Diamond Blades are particularly versatile, applicable...

02

Jun

Troubleshooting Diamond Sawing Problems

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

09

Sep

Understanding Tradeoffs – Searching for Perfect Diamond Drill & Tool

Choosing the right diamond drill or tool can significantly impact efficiency, cost, and quality. However, this is not a simple and clear-cut process. Selecting the optimal drill or tool involves navigating a complex landscape of...

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin, high precision cutting blades, precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use