DIAMOND WAFERING BLADES – CASE STUDIES

-

Posted by

contactor6

Cutting Parameters

Load: 80 grams Blade Dressing: Prior to each cut Wheel Speed: 10 maximum on dial) Coolant Density: 30:1

Each cut was timed and recorded, with each cut averaged for each sample and then plotted in a graph.

Results: New Generation, Sintered (metal bonded) Diamond Wafering Blades with SMART CUT technology cut substantially faster than Conventional Sintered (metal bond) diamond wafering blades. For all three materials.

Cutting Times of Various Materials Using Different Diamond Wheels

(All samples 12mm rods)

New Generation Metal Bond

Diamond Wafering Blades Conventional Metal Bond

Material with SMART CUT™ technology Diamond Wafering Blades

Quartz 4.5 minutes 10 minutes

Aluminum 26 minutes 29.5 minutes

Brass 25.5 minutes 33.5 minutes

Conventional Diamond Wafering Blade: is a well known "Brand Name" Diamond Wafering Blade in metallography, material science, & sample preparation industry.

Case Study No. 2

A small rod of 100 steel: 6 chromium 15mm in diameter by 35mm in length was obtained for cutting tests. Three cuts were made to evaluate cutting time, surface finish, and accuracy of the cut (parallelism) using different diamond wheels. The surface of the part following cutting was inspected using an inverted optical microscope at low magnification to qualitatively compare surface roughness. The width of the sample following cutting (the thickness) was measured to determine if any significant variation was observed in the specimens. Finally, a comparison of cutting times was made to compare the wheel cutting efficiency as well. The sample rod material was cut using similar conditions for each diamond wheel.

The sample was mounted onto the Model 650 Low Speed Diamond Wheel Saw using a Model 65006 Vise sample holder. A water-soluble coolant was used to prevent excess heating during the cutting process, and was replenished after each cut. Cutting load was applied to the specimen directly onto the arm mechanism, and the counter-balancing weight was used to prevent wheel binding during the cutting process. A total cutting load of approximately 600 grams was used with the diamond wheel saw during each cut, and dressing of the blade was done periodically every hour during the cutting process.

Cutting times and thickness variations of diamond wheels cutting 100 Steel: 6 Chromium sample

Wafering Blade Type

Cutting Time

Thickness (mm)

Variation (mm)

SMART CUT™ Diamond Wafering Blade

8 hours

1.940 – 2.070 mm

0.130

Conventional Diamond Wafering Blade

13 hours, 12 min

1.370 – 1.540 mm

0.170

Wafering Blades Tested:

New Generation Metal Bond Diamond Wafering Blade with SMART CUT technology Mesh Size: 120

Conventional Diamond Wafering Blade. Mesh Size: 120 Concentration: High

Conventional Diamond Wafering Blade: is a well known "Brand Name" Diamond Wafering Blade in metallography, material science, & sample preparation industry.

Cutting / Sectioning Materials with a High Metallic Content

Case Study No. 3

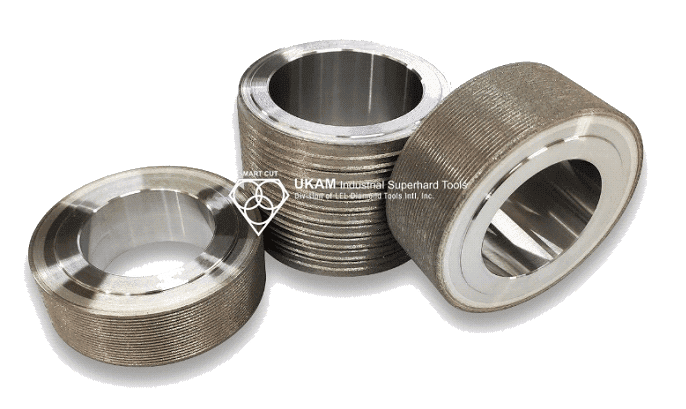

Product: 10” x .040” x ½” New Generation metal bond Diamond Wafering Blade with SMART CUT™ technology

Application: Zr, Nb, Ti, Hf, and their alloys. These are very tough, ductile metals.

Saw Used: Struers Discotom 5 abrasive cut-off saw Blade Life: 4 months

Customer Comments: "We found that it worked well for cutting all of alloys and pure metals. It worked extremely well for sectioning carbide inclusions in Zircaloy. Before using your blade, we have had little success sectioning these types of samples."

Material: cobalt chromium

Specimen Size: 4.0" Saw: South Bay 650

Case Study No. 4

Application: sectioning a client part consisting of a thick stainless steel disk bonded by a proprietary process to an alumina ceramic insulator.

Customer Comments: “ I had previously mounted this combo in epoxy and attempted to cut it on another manufacturer's low speed wafering saw using both their diamond blade and a wafering blade they had recommended for cutting metal. Both blades did well on the ceramic but even with constant dressing the cutting rate in the metal portion of the sample was infinitesimal and I gave up the effort after a whole day of effort. Your blade cut the same sample in approximately 15 minutes on the surface grinder and rates in the stainless steel portion were only slightly slower than in the ceramic. "

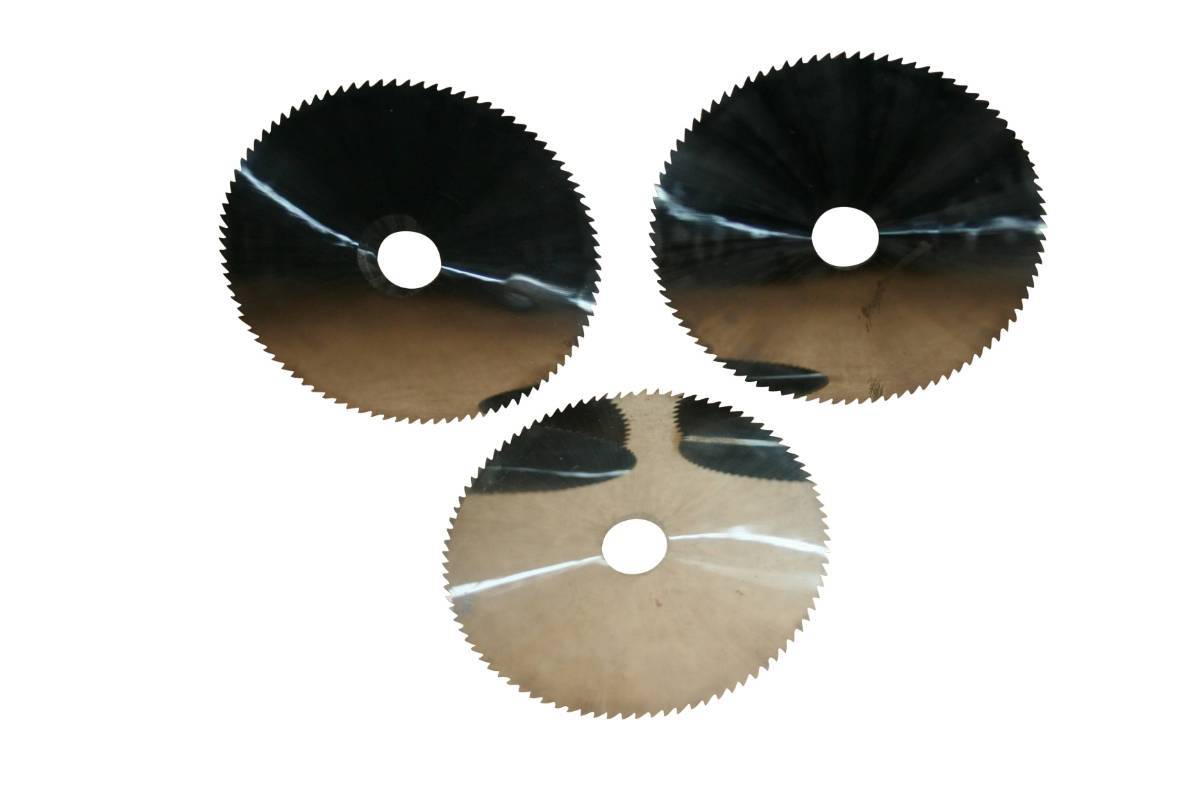

Case Study No. 5

Wafering Blade:

Material:

Specimen Size:

Saw Used:

6” x .020” x ½”

Low Carbon Steel

5/8”

Isomet 1000

Cutting Speeds in Minutes

Smart Cut™ Wafering Blades: 1.51 Conventional Blade: 5.15

Conclusion: SMART CUT™ New Generation Metal Bond Diamond Wafering Blades cut Copper 2.32 times faster

Case Study No. 6

Wafering Blade:

Material:

Specimen Size:

Saw Used:

6” x .020” x ½”

Copper

3/4”

Isomet 1000

Cutting Speeds in Minutes

Smart Cut™ Wafering Blades: 5.59 min Conventional Blade: 13 min

Conclusion: SMART CUT™ New Generation Metal Bond Diamond Wafering Blades cut Copper 2.32 times faster