-

0 items in quote

No products in the Quote Basket.

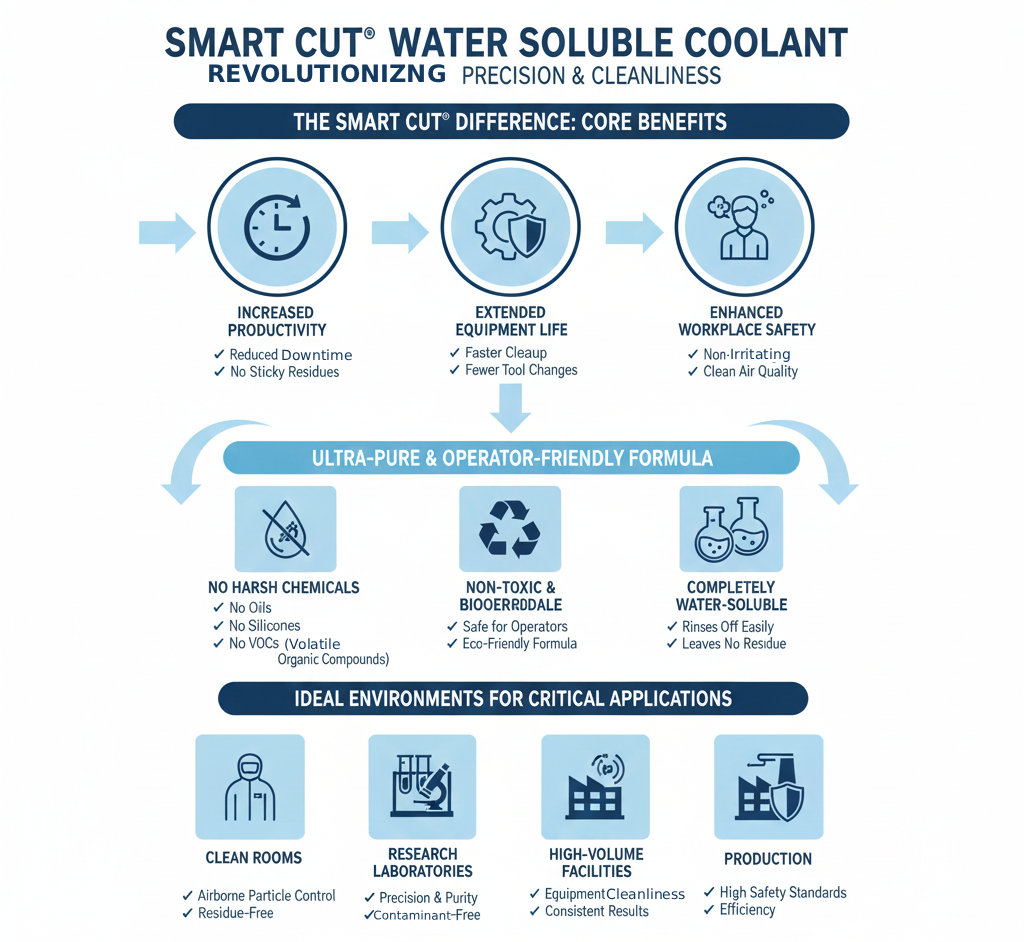

SMART CUT® Coolants For

Diamond & CBN Tools

We manufacture and offer large variety of coolants for many industries and applications. Our SMART CUT® Series of coolants will improve your overall diamond slicing, dicing, sectioning and diamond machining operation by as much as 40%+

SMART CUT® water Soluble Coolant

– General Materials

SMART CUT® General Materials Formula coolant reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material. Since SMART CUT Coolant is a coolant and lubricant, both the diamond tools and material benefit.

General Materials Formula is designed for large variety of materials and applications.

SMART CUT® water Soluble Coolant – Advanced Materials

SMART CUT® Advanced Materials Formula is a Super Premium water soluble synthetic coolant. Considered by many as the highest quality coolant available on the market today. Specially designed and formulated to demand the demands of challenging applications in Photonics/Optics, Advanced Ceramics, Advanced/New Generation Materials, Nano/MEMS Technology Materials & ultra hard & brittle materials. Will benefit manufacturing and R & D facilities by providing the highest level results and consistency required in the challenging growing industries of tomorrow.

SMART CUT® Mineral Oil

SMART CUT® Mineral Oil is not dilatable. Rated as a food-grade mineral oil that is non-toxic, non-hazardous and non-flammable under normal conditions. It has no odor, won't burn your skin (unless you are very sensitive) and has a flash point of 275 degrees - way above normal temperatures.

SMART CUT® water Soluble Dicing Coolant / Fluid / Surficant

SMART CUT® Dicing Coolant (Water Soluble) reduces surface tension flowing from saws injection system and is carried directly of dicing blade. This reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material being processed.

SMART CUT™ HD-2B

Synthetic Low IFT Coolant/Lubricant For Diamond Wire Sawing & ID Cropping Blades, Diamond Band Saws, Edge Grinding of Semiconductor materials

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.

SMART CUT® water Soluble Coolant for Lapping, Grinding, & Polishing

SMART CUT® is an aqueous based synthetic formulation developed to optimize cropping and squaring of silicon ingots using diamond wire. SMART CUT-HD allows the diamond wire to saw properly through the silicon by penetrating through the kerf and wetting the Si/Diamond/Nickel

SMART CUT® Series of coolants are essential for optimal

performance for many applications

Plain water evaporates at 212 F. Often temperature in your cutting zone reaches as much as 500 degrees F. Often water evaporates, before it has a chance of affectively cooling the diamond wheel and material being drilled. Resulting in shorter Diamond Wheel Life, Material Damage or micro cracks associated with overheating. Water may cool your diamond wheel, yet provide poor lubrication properties needed for optimum slicing, dicing, & sectioning results.

SMART CUT® Synthetic Water Soluble Coolant is recommended for:

- Advanced/Technical Ceramics

- Advanced Materials

- Glass

- Quartz

- Optical Materials

- Composites

- Many Types of Natural Stone

- Precious & Semi-Precious Stone

- And Many Other Materials

SMART CUT® Mineral Oil is recommended for drilling:

- Materials with High Metallic Content

- Advanced Ceramics

- Precious & Semi Precious Stone

- Many Other Ultra Hard Materials

Why use Coolants?

Coolants increase productivity and the quality of material preserve true material micro structure,& minimize material deformation. Coolants increase the time interval between tooling changes. This saves you money by reducing the number of tool or die changes needed. Tooling changes require the shut down of the production lines, therefore less tooling changes will increase productivity. Modern coolants must fulfill two primary functions: cooling and lubrication. Both of these functions are important, but their relative importance depends on the type of operation and material being processed.

Cooling

Prior to modern high-speed equipment, cooling from a lubricant was not needed. The slow cutting speeds did not generate much heat. The straight lubricants were able to transfer enough heat to avoid damage to the parts and tools. However, modern equipment operates at high speeds. This high speed movement creates tremendous amounts of heat which must be removed by the coolant. Failure to remove the heat and chips in the contact zone, between the cutting tool and the part will shorten tool life and increase the number of tool changes as well as reduce the tolerances of tooling and part because of thermal expansion.

Lubrication

Lubrication provided by the coolant reduces the friction between the tool and material / substrate. The coolant prevents the substrate from sticking to the tool and will increase the surface finish. Some companies are trying to eliminate coolants, which inevitably increase the amount of money spent on tooling and lost production. But some companies feel that this is worth the cost benefit of maintaining the coolant systems and the work associated with the coolants. These companies are in the minority.

Related Products

SMART CUT® Water Soluble Coolant

(General Materials Formula)

High-Performance Fully Synthetic Coolant & Lubricant for Diamond Slicing, Dicing, Drilling, and Grinding & Machining of Ceramics, Glass, Optics, Quartz, Silicon, and Other Hard & Brittle Materials

SMART CUT® Water Soluble Coolant (General Materials Formula) is a fully synthetic, non-oily, and non-foaming coolant and lubricant engineered to meet the rigorous demands of slicing, dicing, drilling, sectioning, wafering, grinding, and polishing operations involving hard and brittle materials. This advanced formula has been specifically developed for use with ceramics, precision optics, quartz, silicon, sapphire, and other materials commonly found in semiconductor, photonics, and materials research applications.Dressing Sticks For Precision Diamond & CBN Tools

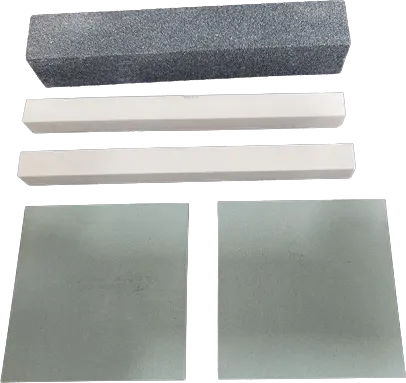

Diamond Tools must be used with diamonds exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and heat cracks in the diamond tool as well as material being machined. Resulting in premature diamond tool wear, blade tensioning problems, and will eventually destroy the diamond tool. The more a diamond tool is dress the cooler it will drill or cut. Everything you wanted to know about dressing Diamond & CBN Tools

SMART CUT® Dressing Sticks are expertly designed to help you clean, sharpen, and condition your diamond blades, grinding wheels, and other diamond tooling, ensuring optimal performance and extended tool life. Available from stock in many different dimensions, abrasive types, grit size, and bond harnesses to fit most requirements. Manufactured in the USA with premium-grade materials, these dressing sticks are an essential accessory for any industry relying on precise cutting, drilling, grinding, & operations. Custom specifications can be produced upon request with fast lead times & small minimum order quantities.

SMART CUT® HD Synthetic Low IFT Coolant/Lubricant For Diamond Wire Sawing Silicon

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.