Diamond Core Drill Bit Guide: How to Choose the Right One for Precision Cutting (USA)

-

Posted by

contactor6

Table of Contents

ToggleChoosing the correct diamond core drill bit is one of the most important decisions for achieving precision drilling, faster cutting speeds, and longer tool life. Whether you’re drilling concrete, granite, porcelain tile, marble, or masonry, your bit selection directly impacts efficiency, hole quality, and overall project cost.

This USA-focused buyer’s guide explains exactly how to select the right bit for your application while avoiding the most common performance and durability mistakes.

What Is a Diamond Core Drill Bit?

A diamond core drill bit is a cylindrical cutting tool embedded with industrial-grade diamonds designed to grind through extremely hard materials. Unlike conventional drill bits that cut using sharp edges, diamond bits abrade surfaces, producing clean, accurate holes with minimal vibration and reduced risk of cracking.

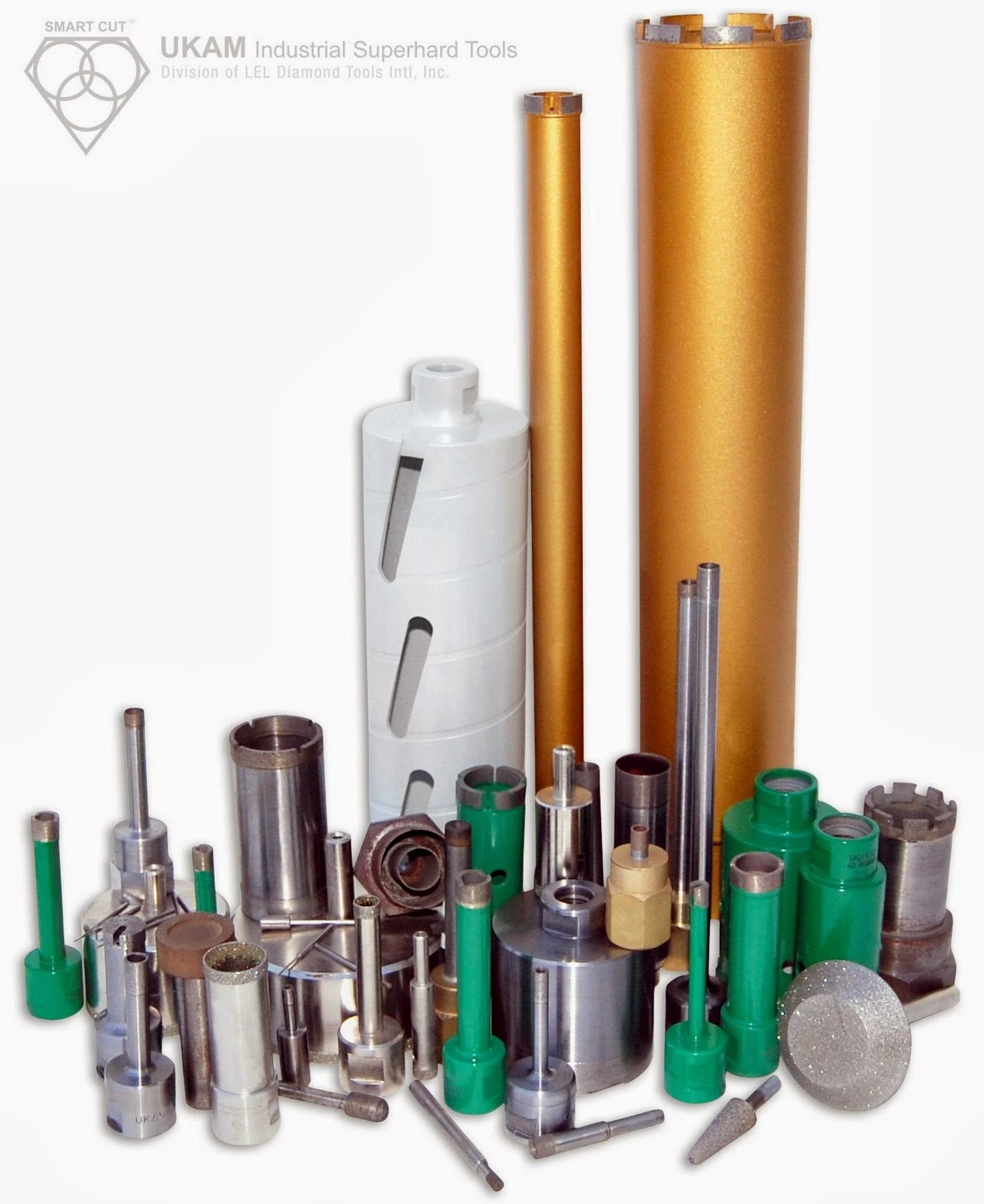

Diamond Core Drill & Tool Types

-

diamond hollow core drills unmounted (tube only)

diamond hollow core drills unmounted (tube only)

-

diamond hollow core drills mounted (with female or male thread or straight shank per client spec)

diamond hollow core drills mounted (with female or male thread or straight shank per client spec)

-

ID Core drills

ID Core drills

-

non core formation

non core formation

-

bottoming drills

bottoming drills

-

diamond dual core drills.

diamond dual core drills.

-

disintegrating drills

disintegrating drills

-

diamond micro drills

diamond micro drills

-

Large Diamond Drills

Large Diamond Drills

-

ultra thin wall diamond core drills

ultra thin wall diamond core drills

-

thin wall diamond core drills

thin wall diamond core drills

-

standard wall diamond core drills

standard wall diamond core drills

-

heavy wall diamond core drills

heavy wall diamond core drills

-

Continuous Rim (Crown) Diamond Core drills

Continuous Rim (Crown) Diamond Core drills

-

Slotted diamond core drills

Slotted diamond core drills

-

segmented diamond core drills

segmented diamond core drills

-

diamond core drills for ultra sonic drilling machines

diamond core drills for ultra sonic drilling machines

-

diamond core drills for ultra sonic drilling machines

diamond core drills for ultra sonic drilling machines

-

concrete & construction diamond core bits

concrete & construction diamond core bits

-

Diamond hole saws

Diamond hole saws

DIAMOND CORE DRILL APPLICATIONS:

They are paired with diamond core drills or a diamond core drill machine depending on drilling depth, diameter, and material hardness.

Why Selecting the Right Diamond Core Drill Bit Matters

Using the wrong bit can lead to:

- Slow drilling speeds

- Excessive heat buildup

- Glazing (diamonds stop cutting)

- Premature segment wear

- Chipped or damaged surfaces

The correct bit improves:

- Precision cutting accuracy

- Drilling speed

- Tool lifespan

- Project profitability

Proper bit selection is not just about compatibility — it’s about optimizing performance.

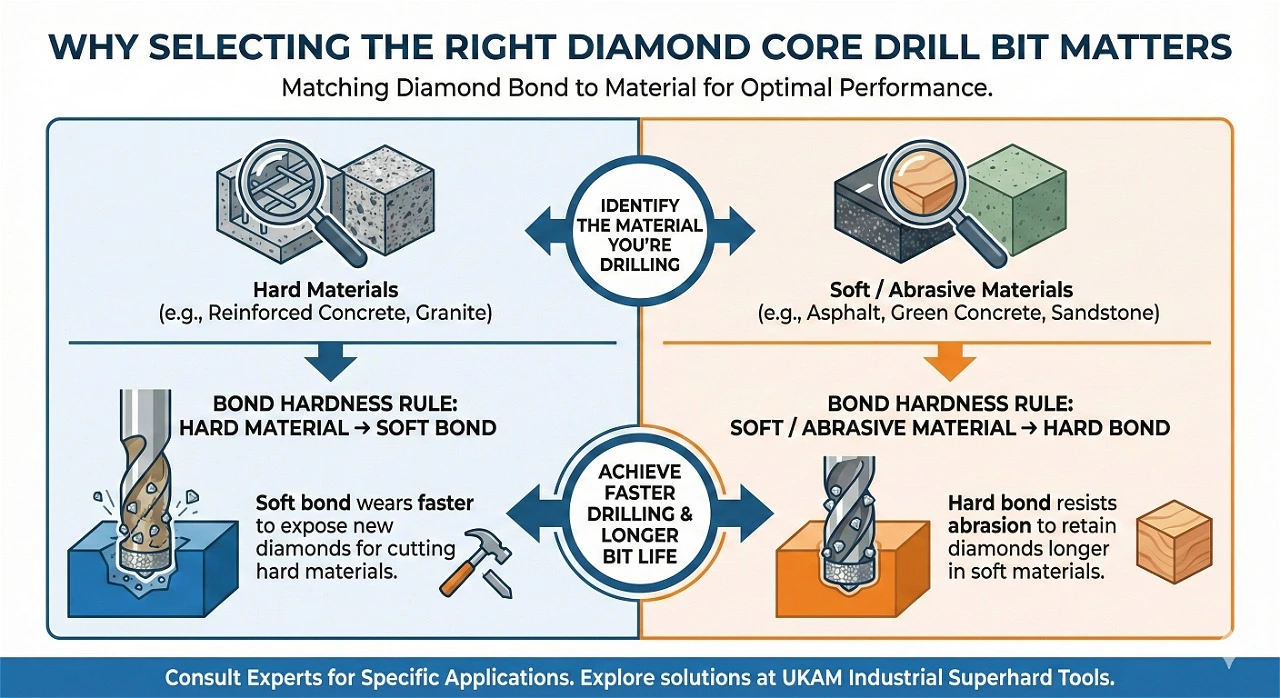

Why Selecting the Right Diamond Core Drill Bit Matters

Identify the Material You’re Drilling

Different materials demand different diamond bond hardness.

Bond Hardness Rule:

- Hard material → Soft bond

- Soft / abrasive material → Hard bond

|

Material Type |

Ideal Bond |

|---|---|

|

Granite / Porcelain |

Soft bond |

|

Marble / Limestone |

Medium bond |

|

Concrete / Masonry |

Hard bond |

Why this matters:

Hard materials dull diamonds quickly, so a soft bond exposes fresh diamonds faster. Softer materials wear the bond quickly, requiring a harder matrix.

Wet vs Dry Diamond Core Drilling

Wet Drilling (Recommended for Most Jobs)

Benefits:

- Superior cooling

- Faster drilling

- Cleaner holes

- Extended bit life

- Reduced dust

Best for:

- Concrete

- Stone

- Tile

- Glass

Dry Drilling

Benefits:

- No water setup

- Faster mobility

- Cleaner jobsite logistics

Requires:

- Proper airflow

- Vacuum/dust extraction

- Heat management

Best for:

- Light masonry

- Fast, shallow drilling

Tip: Even dry bits benefit from intermittent cooling pauses.

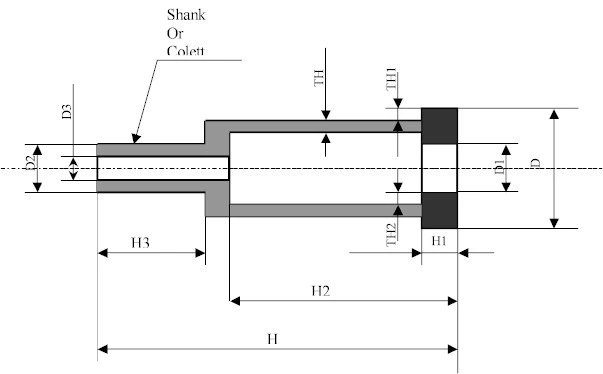

Choose the Correct Bit Diameter & Depth

Select the right diamond core drill bit based on the final hole requirement.

Consider:

- Anchor holes

- Plumbing penetrations

- Electrical conduit

- Fastener installations

Small diameter bits provide faster precision holes.

Large diameter bits handle structural penetrations.

Diamond Quality & Concentration

Higher diamond concentration typically results in:

- Longer bit lifespan

- More consistent cutting

- Better performance on dense materials

Premium-grade bits engineered by specialists like UKAM Industrial Superhard tools are designed for optimal diamond exposure and wear resistance.

Low-quality bits may appear cheaper but often cost more in replacements and downtime.

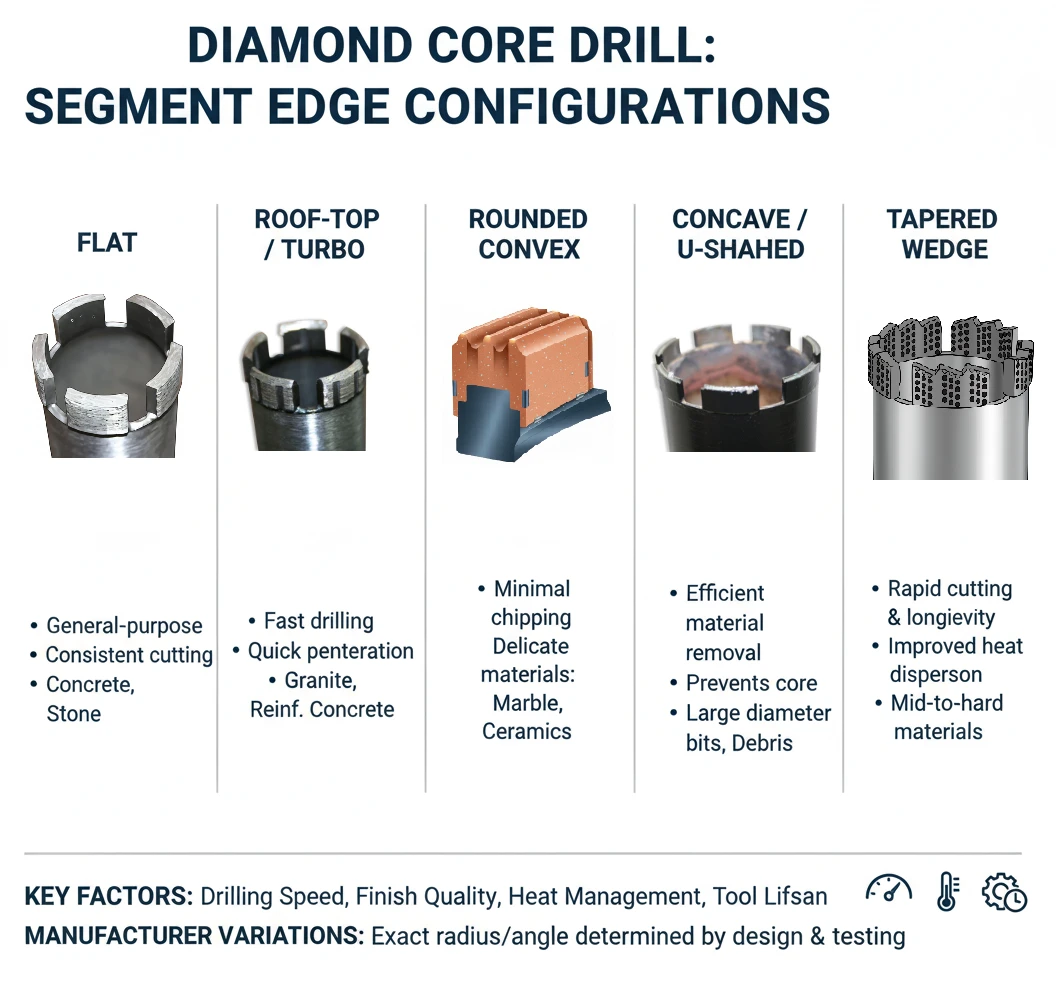

Segment vs Continuous Rim Design

Diamond core drill bit guide

Segmented Rim Bits

Advantages:

- Faster cutting

- Better debris removal

- Improved cooling

- Ideal for concrete & stone

Continuous Rim Bits

Advantages:

- Ultra-smooth finish

- Reduced chipping

- Best for tile & glass

Table comparing continuous rim, slotted, and segmented diamond core drills:

|

Feature |

Continuous Rim Diamond Core Drills |

Slotted Diamond Core Drills |

Segmented Diamond Core Drills |

|---|---|---|---|

|

Cutting Edge Design |

Smooth, uninterrupted edge |

Slots or gaps along the cutting edge |

Individual segments separated by gullets |

|

Best for Material Type |

Soft to medium-hard, delicate materials (e.g., tile, ceramics) |

Harder materials requiring quick drilling (e.g., concrete, stone) |

Hard, dense, and abrasive materials (e.g., granite, reinforced concrete) |

|

Cut Quality |

Very smooth, chip-free finish |

Moderate finish, some chipping possible |

Rougher cut, more chipping |

|

Cutting Speed |

Slower due to full contact with material |

Faster drilling with reduced friction |

Fastest cutting for hard materials |

|

Debris Removal |

Less efficient, prone to clogging in deeper holes |

Improved debris removal through slots |

Excellent debris clearance through gullets |

|

Cooling Efficiency |

Best with wet drilling, limited cooling in dry conditions |

Improved cooling via coolant flow through slots |

Superior cooling due to air/water flow around segments |

|

Tool Lifespan |

Longer for softer materials, shorter for hard applications |

Balanced lifespan based on material hardness |

Long lifespan, especially for tough applications |

|

Typical Application |

Precision cuts requiring clean edges |

Versatile drilling in hard materials where moderate precision is needed |

Heavy-duty drilling, deeper holes, and fast removal of hard materials |

Drill Speed (RPM) Compatibility

Incorrect RPM settings cause:

- Overheating

- Glazing

- Segment damage

Always match:

- Bit diameter

- Material hardness

- Manufacturer recommendations

How to Recognize Proper Diamond Core Drill Bit Performance

Signs you chose correctly:

- Steady drilling speed

- Minimal vibration

- Clean hole edges

- Even segment wear

- No burning smell

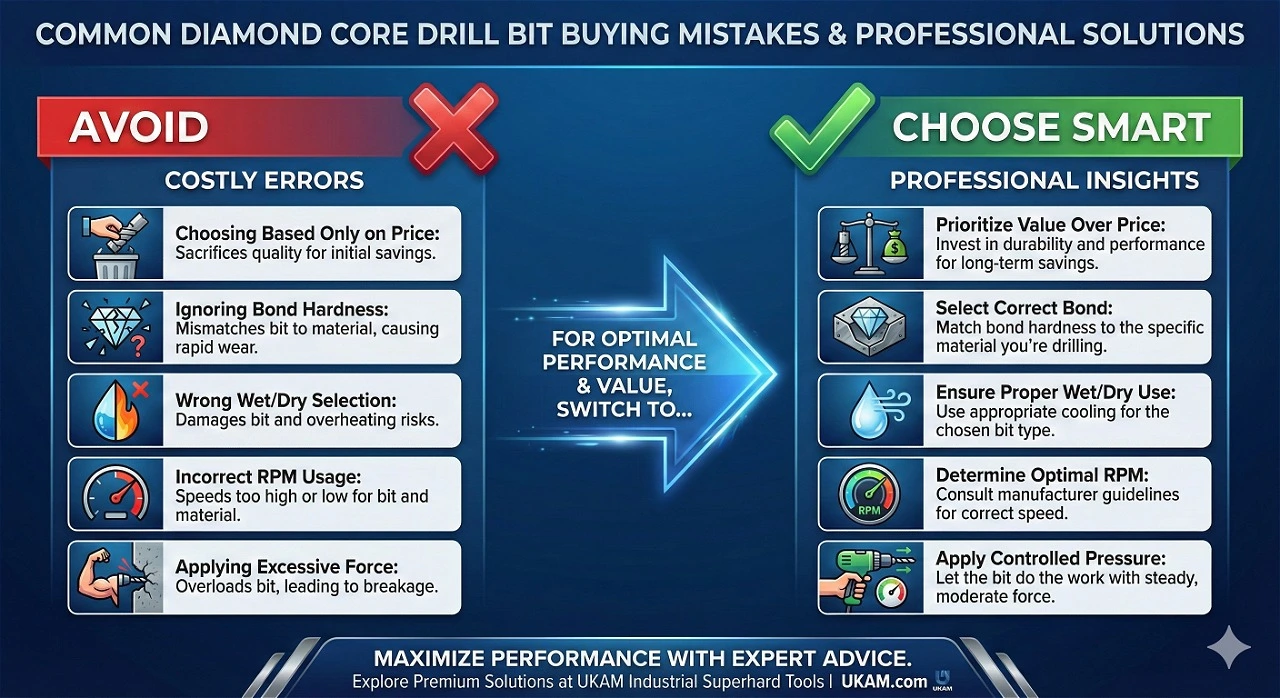

Common Diamond Core Drill Bit Buying Mistakes

Avoid these costly errors:

- Choosing based only on price

- Ignoring bond hardness

- Wrong wet/dry selection

- Incorrect RPM usage

- Applying excessive force

Remember:

Diamond tools grind — they should not be forced.

How Professionals Maximize Diamond Core Bit Lifespan

Industry best practices:

- Maintain correct RPM

- Apply consistent pressure

- Use cooling (water/airflow)

- Avoid overheating

- Clear debris/slurry regularly

- Dress glazed bits

How to Fix a Glazed Diamond Core Drill Bit

If your bit stops cutting:

- Drill into abrasive material (soft brick/dressing stone)

- This exposes fresh diamonds

- Restores cutting efficiency

Diamond bits do not “sharpen” traditionally. Guide on how to properly dress diamond core drill bits

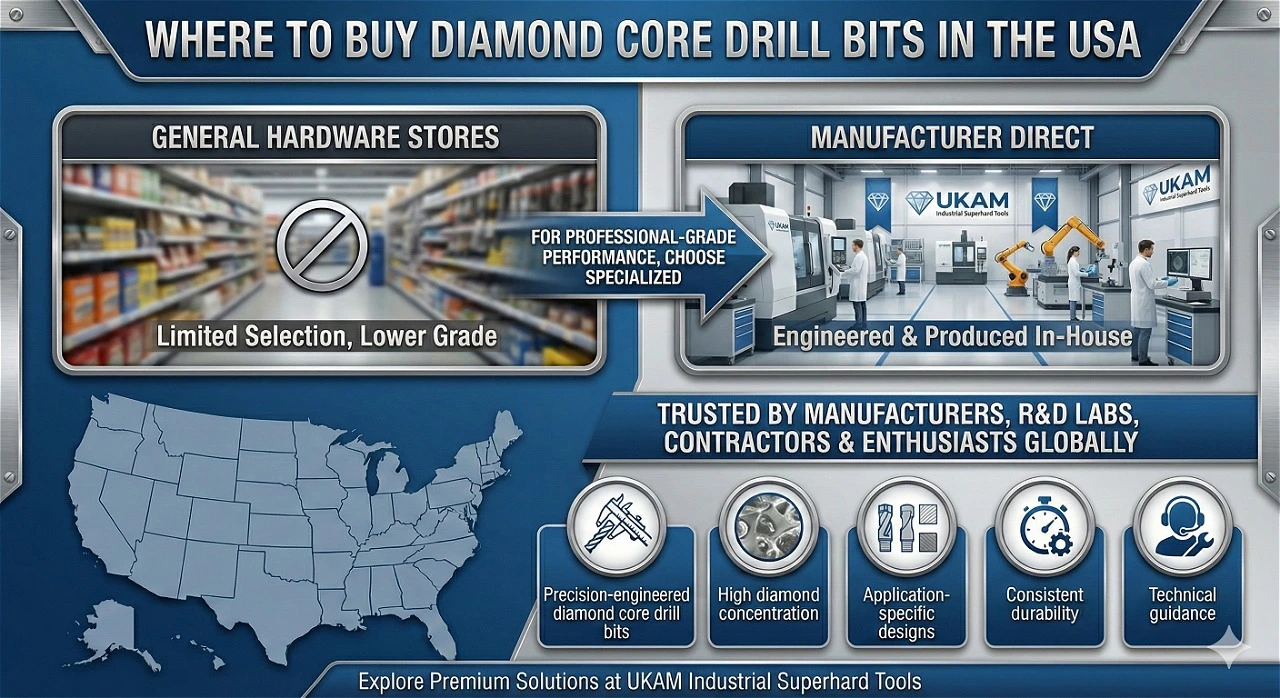

Where to Buy Diamond Core Drill Bits in the USA

For professional-grade performance, purchase from specialized industrial suppliers rather than general hardware stores.

Manufacturers, R & D labs, Contractors and hobby enthusiast across United States adn around the world often choose UKAM Industrial Superhard tools for:

- Precision-engineered diamond core drill bits

- High diamond concentration

- Application-specific designs

- Consistent durability

- Technical guidance

When buying, look for:

- Material compatibility charts

- RPM recommendations

- Wet/dry specifications

- Quality manufacturing standards

Ready to Improve Your Drilling Precision?

Investing in the right diamond core drill bit dramatically improves:

- Hole accuracy

- Cutting speed

- Tool lifespan

- Jobsite efficiency

Explore industrial-grade diamond core drill bits designed for demanding applications at UKAM Industrial Superhard tools.

Frequently Asked Questions

A diamond core drill is a drilling machine designed specifically to operate with diamond core drill bits. It uses rotary motion and controlled pressure to grind holes through concrete, stone, tile, masonry, and other hard materials.

Diamond bits are refreshed, not sharpened.

- Drill into abrasive material (soft brick/dressing stone)

- This removes glazing

- Exposes fresh cutting diamonds

Purchase from specialized industrial suppliers. In the USA, professionals often source from manufacturers like UKAM Industrial Superhard tools for consistent quality and performance reliability.

Basic usage steps:

- Secure work surface

- Set correct RPM

- Start drilling slowly

- Apply steady pressure

- Use cooling (water for wet drilling)

Avoid forcing the bit — diamonds grind naturally.

The best bit depends on:

- Secure work surface

- Wet or dry drilling

- Hole diameter

- Cutting depth

- Drill compatibility

Premium-grade bits typically deliver superior durability, speed, and precision.

Final Thoughts

Selecting the correct diamond core drill bit is essential for achieving precision cutting, faster drilling, and reduced replacement costs. By matching bond hardness, drilling method, segment design, and RPM compatibility, professionals can significantly improve both performance and profitability.

For demanding drilling applications in the USA, high-quality solutions from UKAM Industrial Superhard tools help ensure reliability, accuracy, and long-term value.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990