SMART CUT® Diamond Carving Points

SMART CUT® Diamond Carving Points

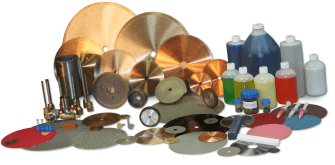

UKAM Industrial Superhard Tools manufactures & offers a large variety of diamond carving points.

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms, milling, deburring, Thread grinding.

These tools are used on large variety of ultra hard, dense, and brittle materials, such as advanced ceramics (alumina, silicon carbide, boron nitride, boron carbide, pzt, sapphire, silicon, yag, quartz. Glass, crystals, large variety of natural and semi precious stones, composite materials, ferrous and non ferrous metals, carbide, ceramics, ferrites tough alloys and cements, and many others.These tools are used on large variety of routers, jig grinding machines, hand pieces, milling machines, etc. Operating speeds : 15,000 to 35,00 rpm’s range. These are available in 4 bond types.

Diamond Bond Types

- Sintered (metal bond)

- Resin Bond

- Nickel Bond (electroplated/galvanic)

- Brazed Bond

Tool Types

- Diamond Points,

- Reamers

- Diamond Mandrels

- Diamond Counter Tools

- Diamond Routers

- Diamond Chamfer Tools

- Diamond Radius Tools

- Diamond Profiling Tools

- Diamond Ball Nose Tools

- Diamond Full Ball Tools

- Diamond Bottom Grinding Tools

- Diamond Reamers

- Diamond Threading tools

- Diamond Engraving Tools

- Diamond Radius Tools

- Diamond Chamfer Tools

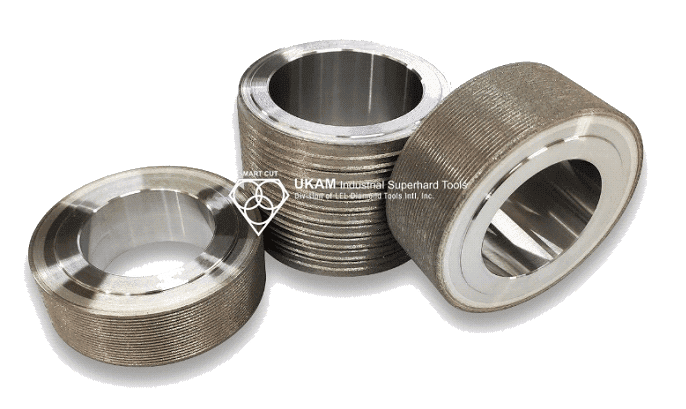

Sintered (Metal Bond) Diamond Carving Points

Designed for carving a wide range of ultra hard to soft material into intricate shapes. The diamond is all the way through cutting tip for maximum efficiency and superior long life. Unlike electroplated diamond carving points, metal bond carving points will continue to work as long as portion of the head still remains. Designed for use with all popular hand held machines &must be used with coolant.

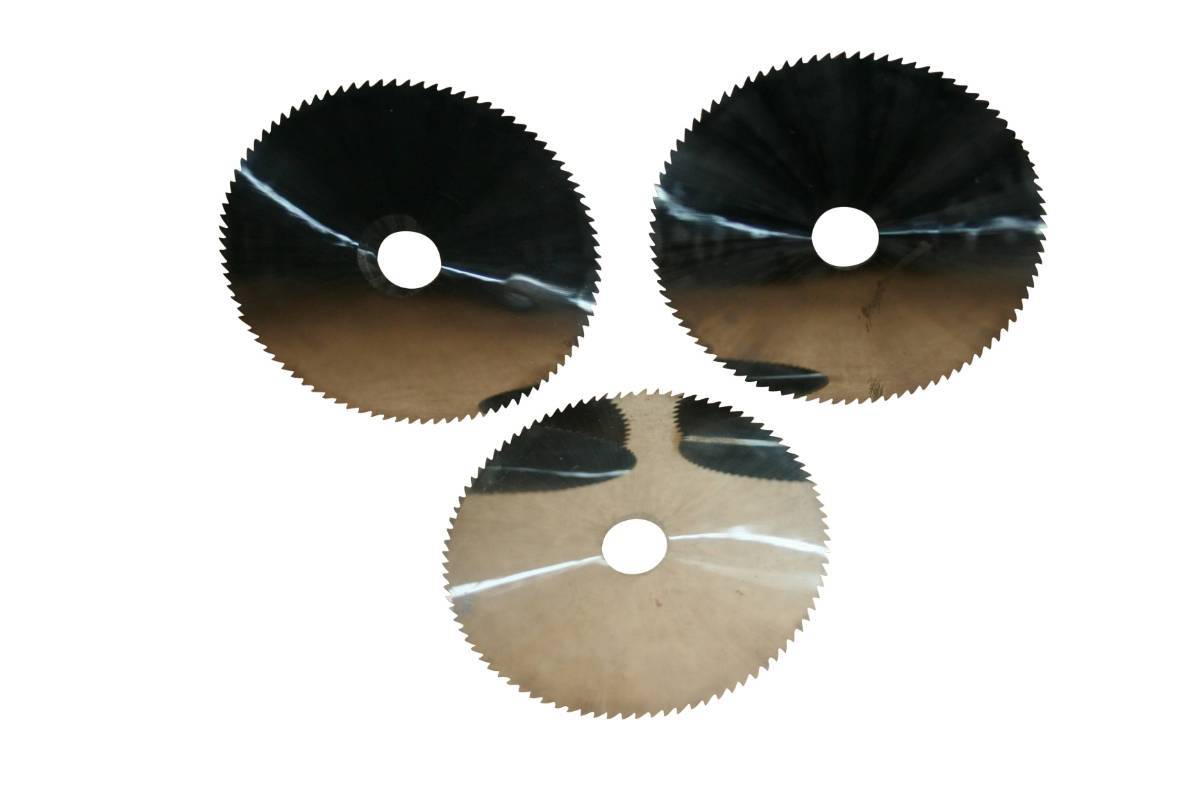

BRAISED BOND DIAMOND CARVING POINTS

Braised Bond diamond carving points last significantly more than electroplated counterparts. They have diamond on the surface, highly exposed. This promotes fast & aggressive cutting action. They are recommended for softer materials or beginning carving enthusiasts. Recommended for marble, softer stones, granite, composites, fiberglass, graphite, and many other soft and gummy materials

Electroplated (nickel bond) carving points

Electroplated (nickel bond) carving points. They are a great buy for beginners just starting to enter the carving field. This 30 piece shapes offers a large variety of cutting options. At very low costs. These are great tools to use for detailing, carving, grinding, and sculpting in a variety of materials. Available in many different shapes, sizes, diamond grit sizes from stock & custom manufactured to your specifications These durable and versatile tools are essential for craftsmen, hobbyists, and professionals seeking to achieve intricate designs and exceptional finishes.

Contact Us For free Quote & Recommendation

ITS WHAT YOU CANT SEE THAT MAKES ALL THE DIFFERENCE

SMART CUT® technology

Let Us Help You:

- Improve Tool Life

- Obtain More Consistent Results

- Preserve True Material Microstructure

- Improve Tool Lite & Overall Performance

- Save Time & Money

- Improve Surface Finish

- Reduce & eliminate Material Deformation

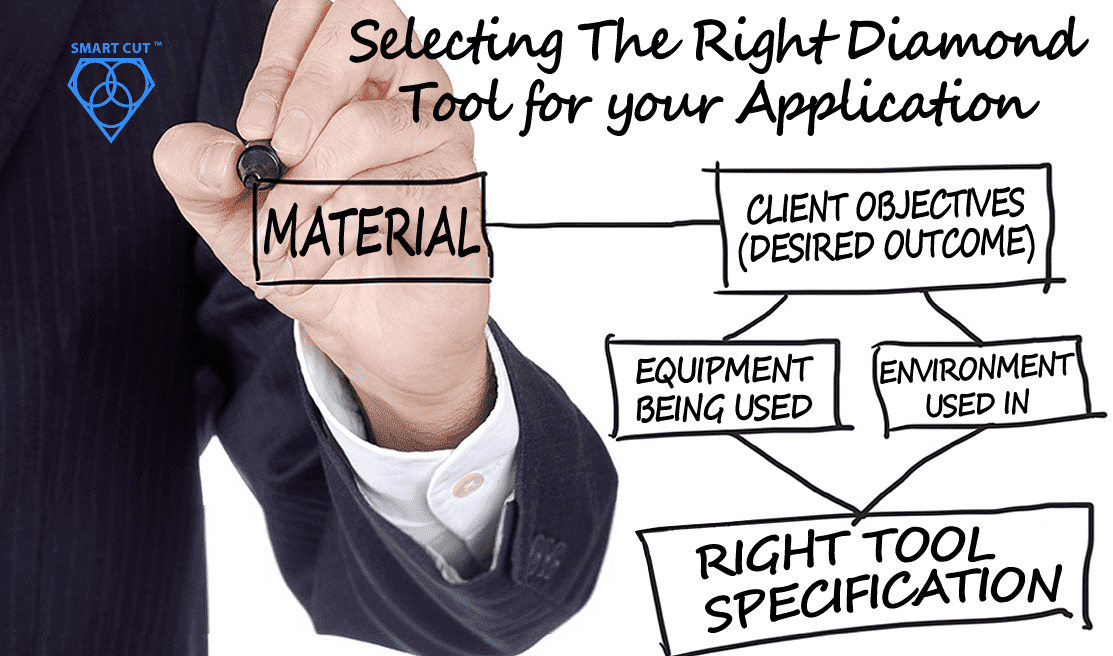

Why Work With Us?

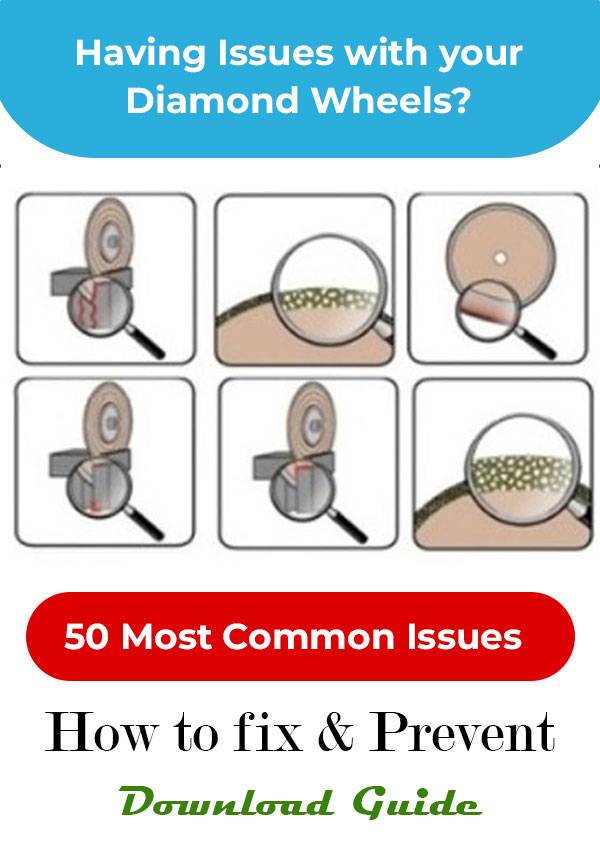

Comprehensive Source Of Information On Diamond Tools

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting, drilling, grinding and polishing on the web. Find everything you ever wanted to know about diamond tools.

Large Inventory & Custom Manufacturing

We have the largest variety of diamond tools available in stock. we regularly produce custom diamond tools to better fit customers specific needs & specifications. Just about any diamond tool can be designed and manufactured per customer drawing or specifications.

Umatched Technical Support

WE ARE A PARTNER IN YOUR SUCCESS

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced Technology

AMERICAN MANUFACTURER

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality & Consistency

Different Product

Different Company

Different Technology

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

EXPECT MORE FROM YOUR TOOLS

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

With a team of highly knowledgeable and experienced engineers, we possess a deep understanding of the challenges you encounter when cutting, drilling, grinding and polishing. This expertise is gained from decades of experience manufacturing sophisticated and high precision tools and equipment for advanced industries and complex applications. Unlike other companies that exclusively focus on tools for the stone and construction industries, we offer unique solutions that surpass their capabilities and expertise.