Products / Services

UKAM Industrial Superhard Tools Manufactures & Provides following Products & Services:

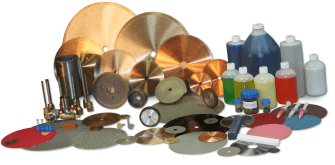

Diamond & CBN Tools, Consumables, Equipment, and Accessories for many industries and applications

Ultra Thin & High

Precision Diamond Blades

UKAM Industrial Superhard Tools is one of the Leading Ultra Thin & High Precision Diamond Blade Manufacturers. Used for Slicing, Dicing, Wafering, Cut-off, Singulation, Grooving, Slotting, Cross Sectioning, Gang Sawing, Slabbing, Rough Cutting. On a full variety of advanced, non-ferrous and ferrous materials, ultra hard materials, precision optics, semiconductors and electronic components with one of the Largest Inventory of Precision Diamond Blades in the U.S.

rom 0.5″ (12.7mm) to 72″ diameter. Used for following industries & applications:

Diamond

Dicing Blades

For all applications and all types of Dicing Saws such as: K & S (Micro-Swiss) + Disco + ADT + Veeco + MECO + MTI + ITI + Meyer & Burger + Surface Grinders + Many Others

rom 0.5″ (12.7mm) to 72″ diameter. Used for following industries & applications:

- BGA Packages

- Alsmag

- FR4 and Resin

- Many Others

- QFN

- LiTaO3 & LiNbo

- PCB

Drilling Solutions

Diamond Drills & Drilling

UKAM Industrial Superhard Tools is a Leading Manufacturer a full range of Precision Diamond Core drills from .001" to 48" Diameter, & Drilling Accessories for drilling just about any Material/Application. Diamond Drills are available from inventory in many different specifications, outside & inside diameters, drilling depths, bond types, diamond mesh sizes, mountings, & tolerances.

We will work with you to determine your needs, and recommend the right solution for your specific material/application

Tools

Diamond Routers, Diamond Points, Profile Tools, & Milling Tools

Large variety of diamond & cbn tools from stock and made to your specifiction using all bond types. Products include:

- Carving Points

- Mounted Points

- Diamond Counter Tools

- Grinding Pins

- routers

- ID Grinding Points

- Jig Grinding Mandrels

- Countersinks

- Counter Bores

- Milling Tools

- Generating Tools

- Face Grinding Tools

- Chamfer Tools

- Radius Tools

- Profiling Tools

- Ball Nose Tools

- Ball Nose Tools

- Bottom Grinding Tools

- Reamers

- Honing Tools

- Endmills

- Threading Tools

Diamond & CBN Wheels

Diamond Wheels and Discs for virtually any application. Whether you are looking for ultra fine finish grinding of exotic material to, fast and aggressive removal of alumina, we can help you get the most out of your grinding process.

Our Diamond Wheels are used Worldwide in Industry, Research & Development, Hobby, and Many Other Applications. Diamond Wheels are available in stock, available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's. Custom Manufacturing to fit your particular requirements with 1 week or less lead time (non minimum order

Metallographic Consumables for

Sample Preparation and R & D

Consumables for materials preparation, metallography, quality control, materials research. For sectioning, rough grinding, fine grinding, polishing.

- Abrasive Cut off Wheels

- Diamond Wafering Blades

- Bonded Abrasives

- Diamond Compounds

- Diamond Suspensions

- Polishing Cloth & Pads

- Diamond Discs

- Abrasive Powders & Slurries

Diamond

Micro Drills & Tools

Micro Diamond Drills are available from .001" to .035" in diameter (25 micros and up)...

Custom

Diamond & CBN Tools

Thousands of diamond tools are available from stock for immediate delivery. Just about any diamond tool can be designed and manufactured per customer drawing or specifications. ver past 50 years, Over 35,000 different types & specification diamond tools have been manufactured...

Diamond

Discs & Laps

Diamond & abrasive grinding, polishing and lapping solutions for many industries and applications for clients in Industry, R & D, and hobby/craft applications.

- Diamond Fixed Abrasive Discs

- Diamond grinding/polishing strips/foils

- Diamond film

- Diamond pellets

Diamond

Band Saw Blades

Diamond band Saw Blades made to order to your specifications, available in any length width from 250 (6.4mm). Available in Electroplated (Nickel Bond), Braised Bond, & Carbide

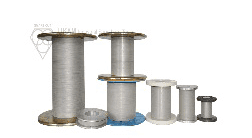

Diamond

Wire Blades

Diamond wire blades made to order from 0.12mm TO 0.42mm diameter available for any spool for just about any wire saw machine.

Diamond Consumables

- Diamond Suspensions - Polycrystalline, Monocrystalline, & Natural

- Diamond paste - Polycrystalline, Monocrystalline, & Natural

- Diamond micro powder - Polycrystalline, Monocrystalline, & Natural

- Diamond Spray - Polycrystalline, Monocrystalline, & Natural

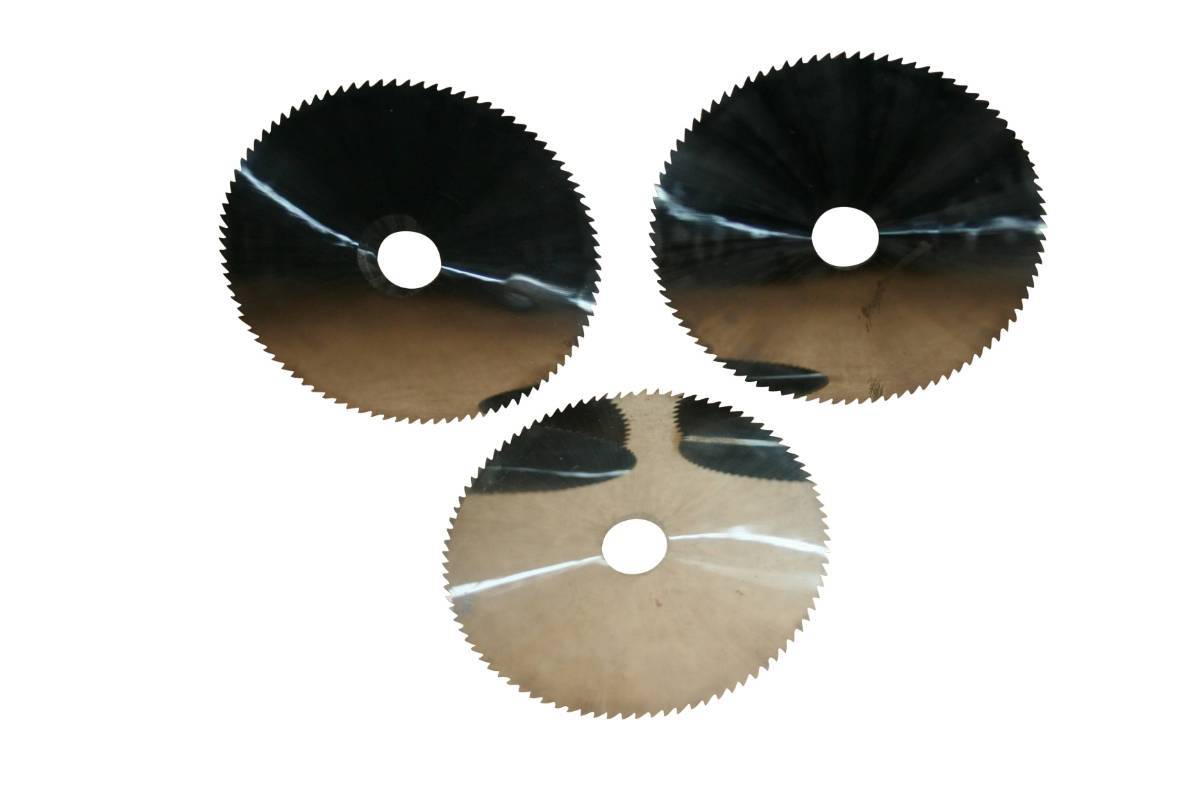

Ultra Thin, High Precision & Micro Carbide Tools

- Ultra Thin & High Precision Carbide Blades for Slicing, Dicing, Slotting, & Grooving - Available as thin as .004" and diameters from 50mm to 500mm

- Micro Carbide Drills & Tooling - Available from small as 20 microns

- Specialized Coatings such as Diamond Like Carbon are available to extend the life of these tools

CVD (Chemical Vapor Deposition)

Diamond Tools

CVD diamond coating takes place in a vacuum chamber using a hot-filament, chemical vapor deposition (CVD) process. Carbon gases are introduced into the vacuum chamber where high temperatures cause carbon atoms to re-bond into a 100% pure crystalline diamond structure.

Precision Abrasives

for Industry, R & D

Abrasive Cut Off Wheels, Abrasive Discs, Abrasive Rolls/Strips, Abrasive Belts, Silicon Carbide (SIC), Zirconia Alumina (ZA), Aluminum Oxide (ALOX), Grinding Wheels - (Aluminum Oxide and Silicon Carbide), Lapping Films (Plain Backed & PSA Backed, Felt Polishing Pads

(Polycrystalline Diamond & CBN) Tools

PCD & PCBN (Polycrystalline Diamond & CBN) Tools

PCD (polycrystalline diamond) is composed of diamond particles that are sintered with a metallic binder at extreme temperatures and pressures, creating the hardest and one of the most abrasion resistant materials used in cutting tools. These inserts are braised on to cutting tools and are used in machining applications in many applications where you find carbide tooling that includes sawing, routing, drilling and profiling to maximize tool life and reduce production cost.

Diamond

Dressers

Diamond dressing tools are made with natural diamond stones set in steel shanks of various shapes for straight or form dressing. For truing and dressing of conventional abrasive grinding wheels. Single point, multi point, chisel shape, straight, angle, and radius configurations.

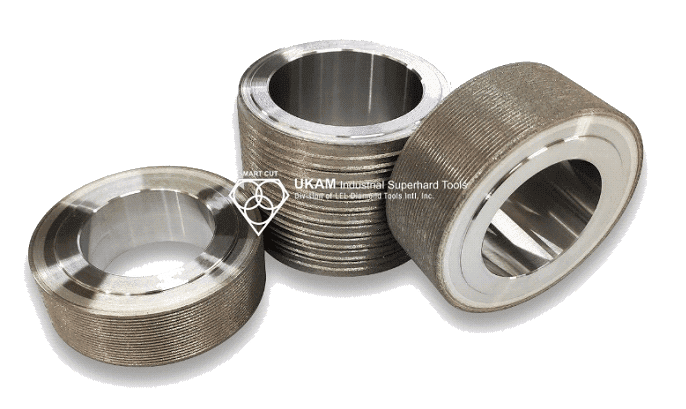

Diamond Rotary

Dressers/Dressing Rollers

Diamond rollers are used to form grinding wheels for many different kinds of mass production. Shorter dressing time and long tool life leads to high productivity and consistent process conditions. Many kinds of conventional grinding wheels, and in special cases super-hard grinding wheels, can be dressed with this dressing method. Dressing rollers can be classified under Diamond profile dressing rollers and Diamond form dressing rollers.

Equipment for

Industry and Research & Development

Precision Cutting Machines for Industry and Research & Development

Complete range of diamond saws, equipment and accessories for cutting (sawing) advanced materials. Such as: ceramics, glass, plastics, quartz, metals, and graphite. From high capacity cutting of very large work pieces to precision cutting of even the most delicate samples. Our diamond saws are widely used in Research and Development, Quality Control, Failure Analysis, as well as Industry

Grinding/Polishing

Equipment for Industry and R & D

6" to 24" (150mm to 609mm) diamond grinding, polishing, & lapping machines for Industry and R & D. Designed coarse & fine grinding and polishing of Advanced, Ultra Hard & Brittle Materials, Optical Materials, Composites. High hardness materials including

Accessories

Diamond Tool

we offer large variety of accessories and consumables for our tools and equipment including:

- Coolants

- Dressing Sticks

- Flanges

- Wheel Stiffieners

- Water Swivel Adapters

Precision Machining Service

Our experienced group of engineers have the equipment and experience to provide full range of

- Dicing

- Slicing

- Drilling

- Micro Drilling

- Grinding

- Polishing

- Machining

Services on wide variety of ultra hard & brittle materials, micro electronics, composites, optics, composites, rocks, glass & many other materials

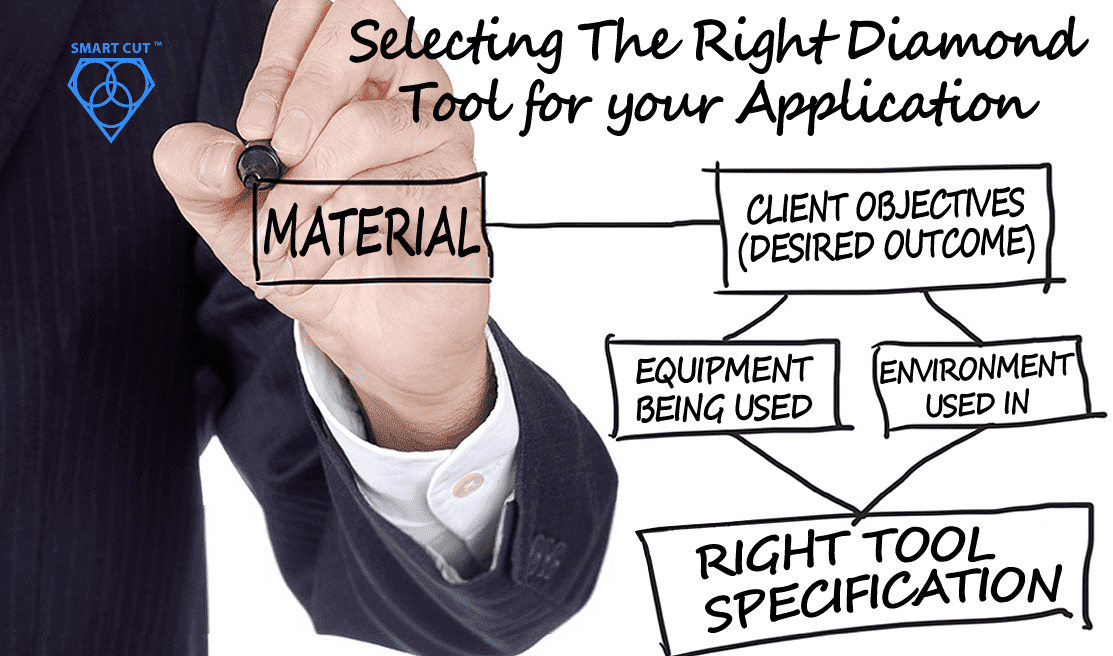

Consulting & Process Development

Our expert team is dedicated to providing comprehensive solutions that are tailored to your specific needs, ensuring you get the most out of our precision diamond tools and services.

Nowadays, only a handful of companies possess world-class expertise. Our team of application engineers has decades of experience in manufacturing, machining, process development, and problem-solving. It's highly likely that we've encountered similar challenges to the ones you're currently facing and have already found a solution

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

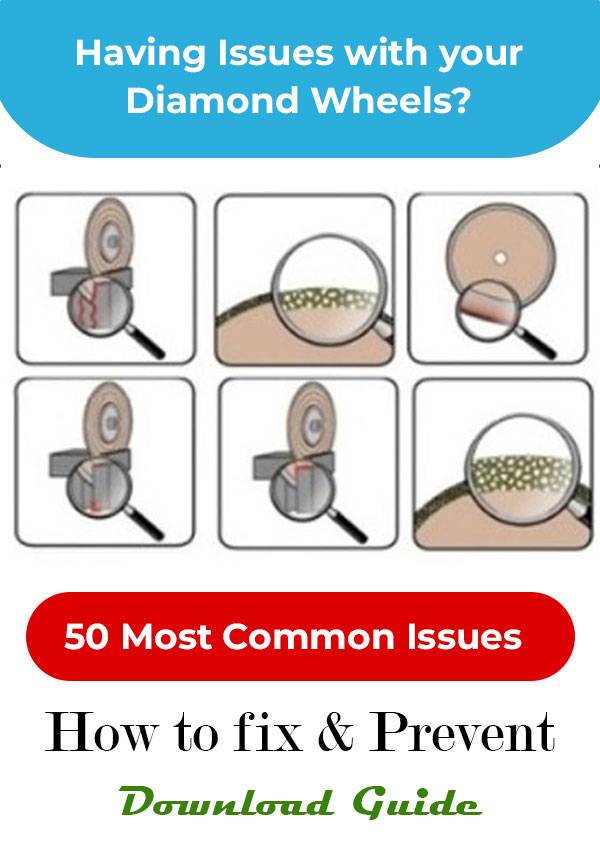

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

How to Selecting Right Diamond Tools for your application

How to properly use Diamond Tools

Why use diamond

What is Diamond Mesh Size and how to select best one for your application

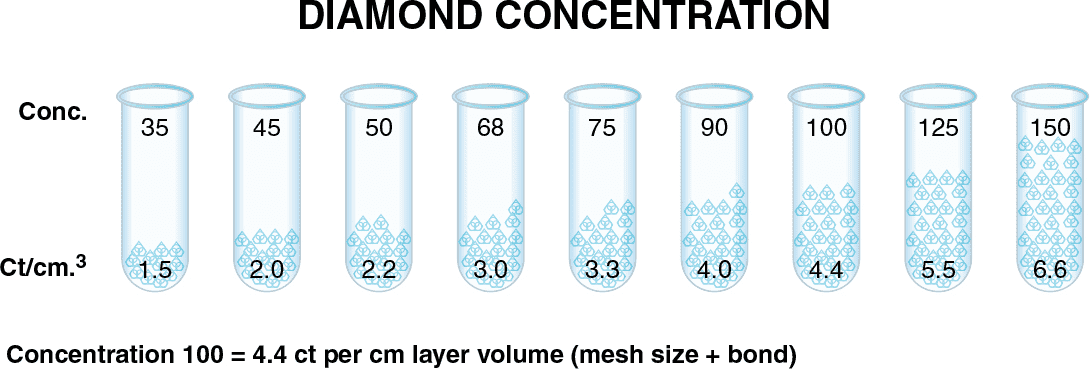

What is Diamond Concentration and which to use for your application

Diamond Tool Coolants Why, How, When & Where to Use

Diamond vs CBN (cubic boron nitride) Tools

Get to Know the Diamond Tool Bond Types and Which to use for your application

Available from stock from 6” (150mm) to 16” (400mm). Kerf Thickness from .014” (0.35mm) to .085” (2.2mm). Arbor sizes: ¾”, 1”, 1.25”, 32mm. we can alter the arbor size to anything you want usually same day (if needed). Available in Many Different Grit Sizes, Concentrations & specifications to fit your requirements

Available from stock from 6” (150mm) to 16” (400mm). Kerf Thickness from .020” (0.5mm) to .085” (2.2mm). Arbor sizes: ¾”, 1”, 1.25”, 32mm. we can alter the arbor size to anything you want usually same day (if needed). Available in Many Different Grit Sizes, Concentrations & specifications to fit your requirements

Available from stock from in continuous rim and slotted designs from 8” (200mm) to 14” (350mm). Kerf Thickness from .020” (0.5mm) to .125” (3.2mm). Arbor sizes: ¾”, 1”, 1.25”, 32mm. we can alter the arbor size to anything you want usually same day (if needed). Available in Many Different Grit Sizes, Concentrations & specifications to fit your requirements

Industries Used On:

- Advanced Ceramics

- Composites

- Glass

- Metallography

- Photonics

- Semiconductor

- Stone

Applications:

- Slicing

- Dicing

- Wafering

- Cut-off

- Cross Sectioning

- Gang Sawing

- Slabbing

- Rough Cutting

- Grooving

Diamond Wire, Diamond Bands Saw Blades, Diamond Blades for Stone & Construction, PCD Blades for wood and plastics, Ultra Thin & High Precision Carbide and Abrasive Cut off Blades

Capabilities & Specifications

- hollow core drills OD or ID: .018" to 22" OD

- solid drills: .002" (50 microns) to 12"

- wall thickness: 0.5mm to 4mm (ultra thin wall, thin wall, standard wall, heavy wall, very heavy wall)

- drilling depth: 5mm to 850mm

- Tolerances: standard tolerance on OD or ID: + / - .004" (100 microns) & special tolerances up to .0005" (12 microns are also available)

- Bond Types: sintered (metal bond), nickel bond (plated), brazed bond

- mounting type: any per client specification, unmounted core drills, wiht female or male thread or straight shank per specification

- drill depth: 4mm to 40"

- diamond grit sizes: 25 mesh to 3,000 mesh

- diamond concentration: low, medium & high

Diamond Core Drill Types:

- Diamond hollow core drills unmounted (tube only)

- Diamond hollow core drills mounted (with female or male thread or straight shank per client spec)

- ID Core drills,

- Non core formation,

- Bottoming drills,

- Diamond dual core drills,

- Disintegrating drills,

- Diamond reamers,

- Diamond chamfering tools,

- Diamond seamers,

- Diamond hole saws

- Ultra thin wall diamond core drills

- Thin wall diamond core drills

- Standard wall diamond core drills

- Heavy wall diamond core drills

- Continuous Rim (Crown) Diamond Core drills

- Slotted diamond core drills

- Segmented diamond core drills

- Diamond core drills for ultra sonic drilling machines

- Concrete & construction diamond core bits

Diamond Solid Drill/Tool Types:

- Diamond carving points

- Diamond mounted points

- Diamond counter tools

- Diamond grinding pins

- Diamond routers

- Diamond ID grinding points

- Diamond jig grinding mandrels/pins

- Diamond countersinks

- Diamond counter bores etc

- Diamond Milling Tools

- Diamond Generating Tools

- Diamond face grinding tools

- Diamond Chamfer Tools

- Diamond Radius Tools

- Diamond Profiling Tools

- Diamond Ball Nose Tools

- Diamond Round End Tools

- Diamond Full Ball Tools,

- Diamond Bottom Grinding Tools

- Diamond Reamers

- Diamond Honing Tools

- Diamond Tapered Hones

- Diamond Threading tools

- Diamond Engraving Tools & Diamond CNC Engraving Tools

- Diamond Profile Tools

- Diamond Radois Tools

- Diamond Radius Tools,

- Diamond Chamfer Tools

- Diamond expanding laps/mandrels

- Diamond endmills

- Diamond hole/bore finishing tools

- Diamond cone grinding tools

- Diamond burs for industry/hobby

Additional options:

slots, radiuses, angles, etc.

Accessories & Related Products Available:

water swivel adapters to run coolant through center, water soluble coolant, dressing sticks

Services:

consulting, process development, drilling services of your material

Capabilities & Specifications

- Diameters Available: 0.5” to 20 OD

- thicknesses available: .004" (100 microns) to any thickness in .0005” (5micron) increments

- arbor sizes available (inside diameters): any arbor size. Standard are ½”, 5/8”, ¾”, 1”, 1.25”, 40mm, 2.75”, 3.5”. For most blades we can alter the arbor size to anything you need, almost same day and if can also produce any arbor size. Blades mounted on straight shank & mandrel available

- diamond type: natural diamond, synthetic diamond, synthetic coated diamond & cbn (cubic boron nitride)

- diamond depth (diamond height) 1.58mm to 20mm and fully impregnated with diamond (from OD to ID)

- Blade Edge Type: Continuous Rim, Slotted, Segmented, Serrated, band saw blades, wire blades

- Blade Core Available: Steel, Stainless Steel, Bronze, Steel with Memory, High carbon steel, tungsten carbide, fully impregnated with diamond

- Edge Shape: 1A1R, 1A1, 1E1, 1M1, 1N1, 1V1, 1A8, 1E8, 1zm8, 1N8, 1V8 (other kerf angles & radiuses can be produced upon request)

- Bond Hardness: Super Soft, Soft, Medium, Hard

- Tolerances Available: ODT tolerances +.050/.000 Arbor Hole Tolerance+.001/-.000 Rim Thickness +.002/-.001 Core Thickness: +.001/-.001

- Bond Types: sintered (metal bond), resin bond, nickel bond (plated), brazed bond, hybrid bond

- diamond grit sizes: 25 mesh to 3 microns

- diamond concentration: low, medium & high (from 10 con to 150 con)

Diamond Abrasive Products (Fixed Diamond)

- Diamond Fixed Abrasive Discs

- Diamond grinding/polishing strips/foils

- Diamond film

- Diamond pellets

Diamond Abrasive Products (Lose Diamond)

- Diamond Suspensions - Polycrystalline, Monocrystalline, & Natural

- Diamond paste - Polycrystalline, Monocrystalline, & Natural

- Diamond micro powder - Polycrystalline, Monocrystalline, & Natural

- Diamond Spray - Polycrystalline, Monocrystalline, & Natural

Fixed Diamond Bonded Tooling)

- Diamond honing tools

- Diamond files

Conventional Abrasive Products (Lose Abrasives)

UKAM Industrial also supplies high precision graded conventional abrasive products for grinding, polishing and lapping. Including abrasive powders, lapping vehicles, premix abrasive slurries, lapping & grinding pastes / compounds, polishing pads, and accessories.

Abrasive Powders (Aluminum Oxide, Silicon Carbide, Boron Carbide, Micro-graded Diamond Powder, Micro-graded Alumina Powder, Cerium Oxide)

Pre-Mixed Abrasive Suspensions / Slurries (Garnet, Aluminum Oxide, Silicon Carbide, or Boron Carbide powder)

Abrasive Grinding, Polishing and Lapping Pastes & Compounds (Aluminum Oxide, Silicon Carbide, or Boron Carbide powder)

Abrasive Grinding, Polishing and Lapping Pastes & Compounds (Aluminum Oxide, Silicon Carbide, or Boron Carbide powder)

Polishing Pads (Used for polishing a wide variety of materials including metals, glass, semiconductor materials, and more)

Conventional Abrasive Products (Fixed Abrasives)

UKAM Industrial also supplies large variety of fixed abrasives for sample preparation/metallography. Including

- Abrasive Discs,

- Abrasive Rolls/Strips

- Abrasive Belts

- Silicon Carbide (SIC)

- Zirconia Alumina (ZA)

- Aluminum Oxide (ALOX)

- Grinding Wheels - (Aluminum Oxide and Silicon Carbide)

- Lapping Films (Plain Backed & PSA Backed

- Polishing Pads - (Used for polishing a wide variety of materials including metals, glass, semiconductor materials, and more)