Photonics

Diamond Tools for

Photonics Industry

UKAM Industrial Superhard Tools specializes in manufacturing Precision Diamond Tools for Photonics and Precision Optics industries. We understand the problems you are facing in machining glass/quartz materials and stepped up to meet this challenge by developing Diamond Products and technology that will help achieve closer tolerances and smoother surface finish. As leader in new product development, we continue to raise standards for the whole industry. Rely on us to improve and optimize you photonics & precision optics fabrication operation to its ultimate level of efficiency.

Photonics/Optical Glass Materials

- EXCIMER GRADE

- FUSED SILICA

- ZERODUR

- Boron Nitride

- CaF2

- TEMPAX

- GLASS BOROFLOAT

- GERMANIUM VARIOUS

- FLINT TYPES

- ZNSE VARIOUS

- CROWN TYPES

- ZNS VARIOUS

- FILTER TYPES

- ULE QUARTZ

- STAINLESS STEEL

- YAG ALUMINIUM

- BK-7 IR MATERIALS

- ZKN-7

- SILICON PYREX

- MANY OTHERS

Solutions

For Cutting Photonic Materials

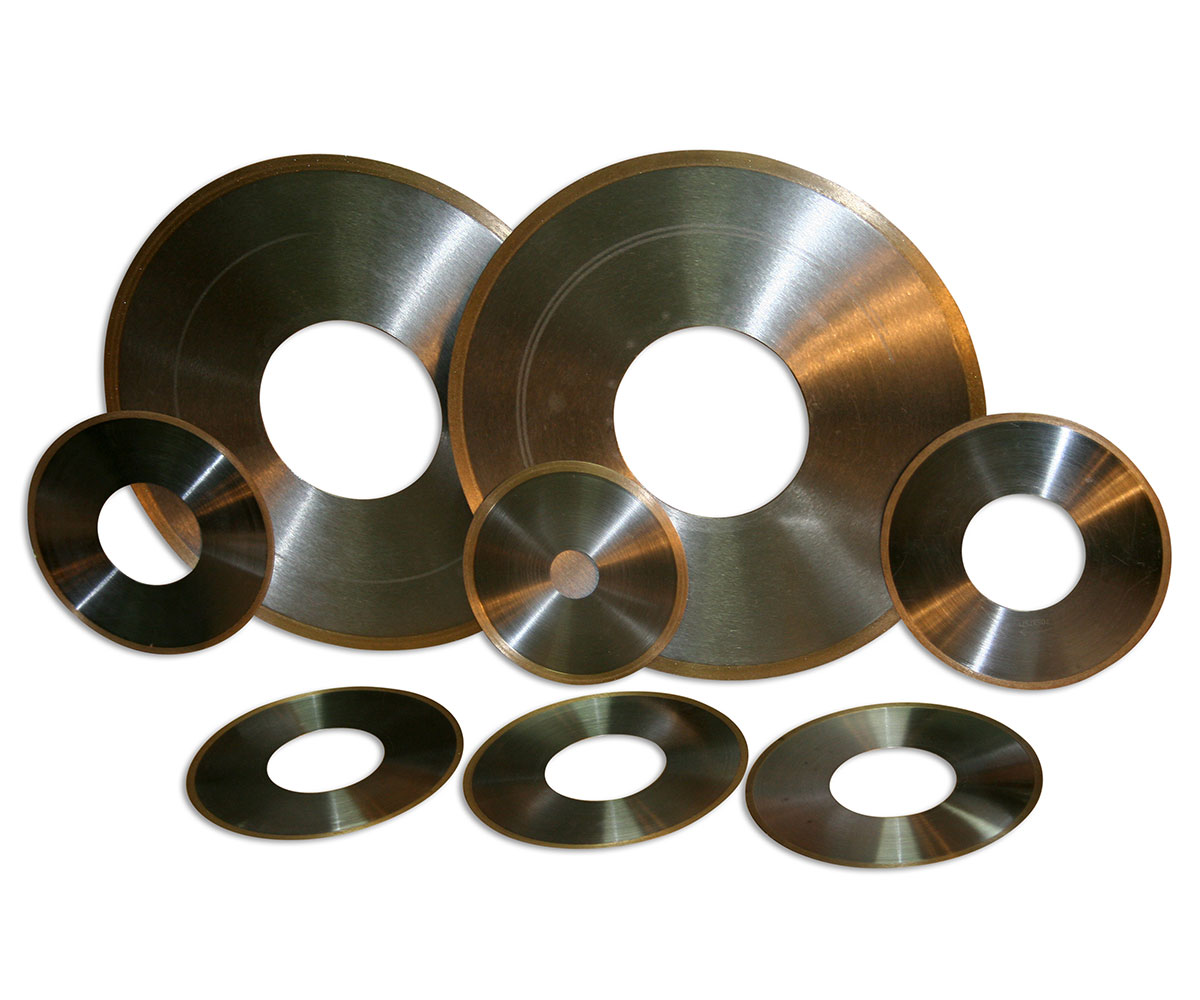

Thin & High Precision Diamond Blades<; from 0.5” to 48” OD, starting .004”. Used for cutting large variety of optical glass. Bond Types available: sintered (metal bond), resin bond, nickel bond, braised bond. Precision Diamond Blades are available from inventory in many different specifications, diamond concentrations, mesh sizes, bond hardness, & inside diameters. We will work with you to determine your needs, and recommend the right parameters for your specific material/application.

Precision Cutting Machines

For Photonic Materials

Complete range of diamond saws, equipment and accessories for cutting (sawing) advanced materials. Such as: ceramics, glass, plastics, quartz, metals, and graphite. From high capacity cutting of very large work pieces to precision cutting of even the most delicate samples. Our diamond saws are widely used in Research and Development, Quality Control, Failure Analysis, as well as Industry

SOLUTIONS FOR

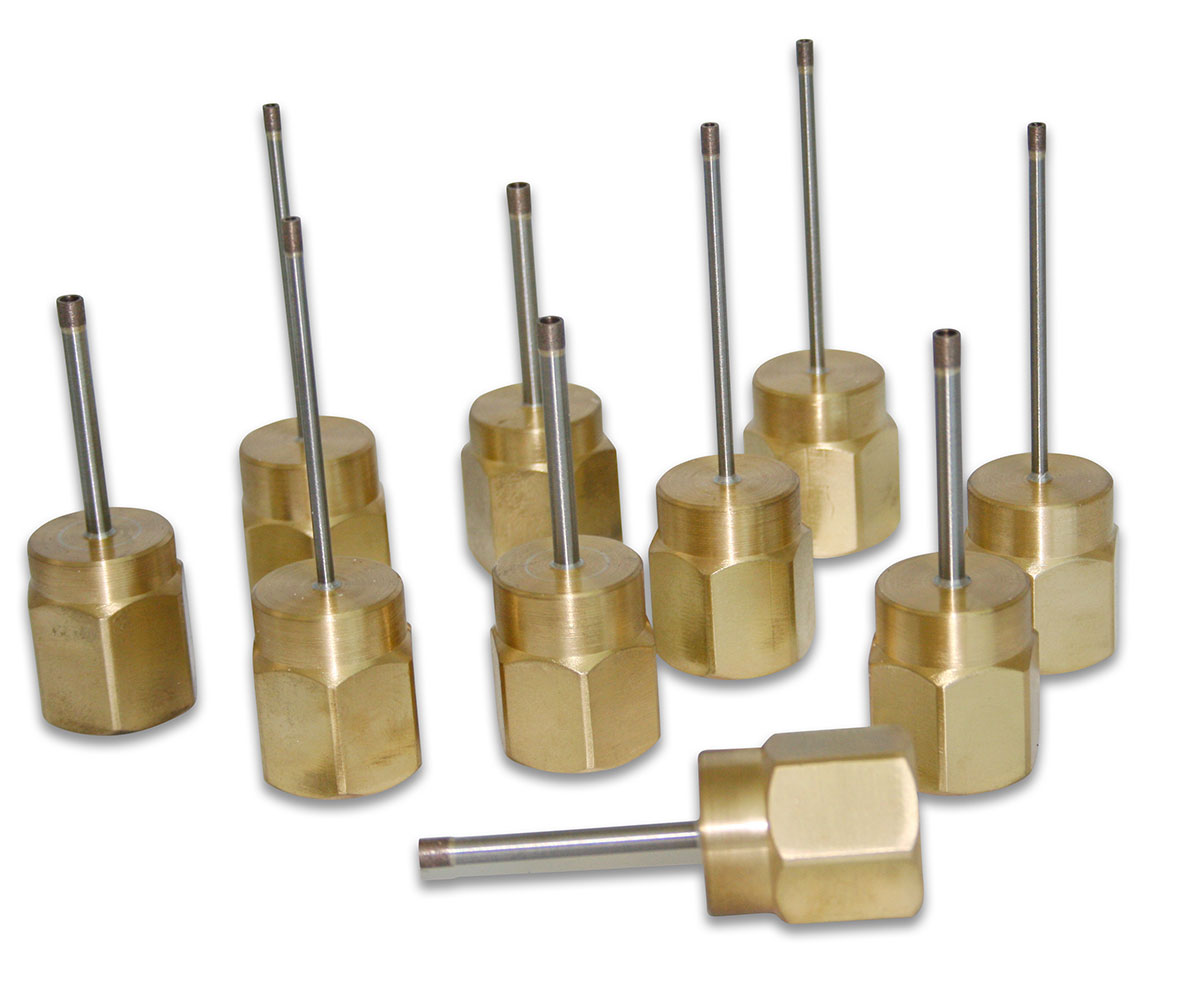

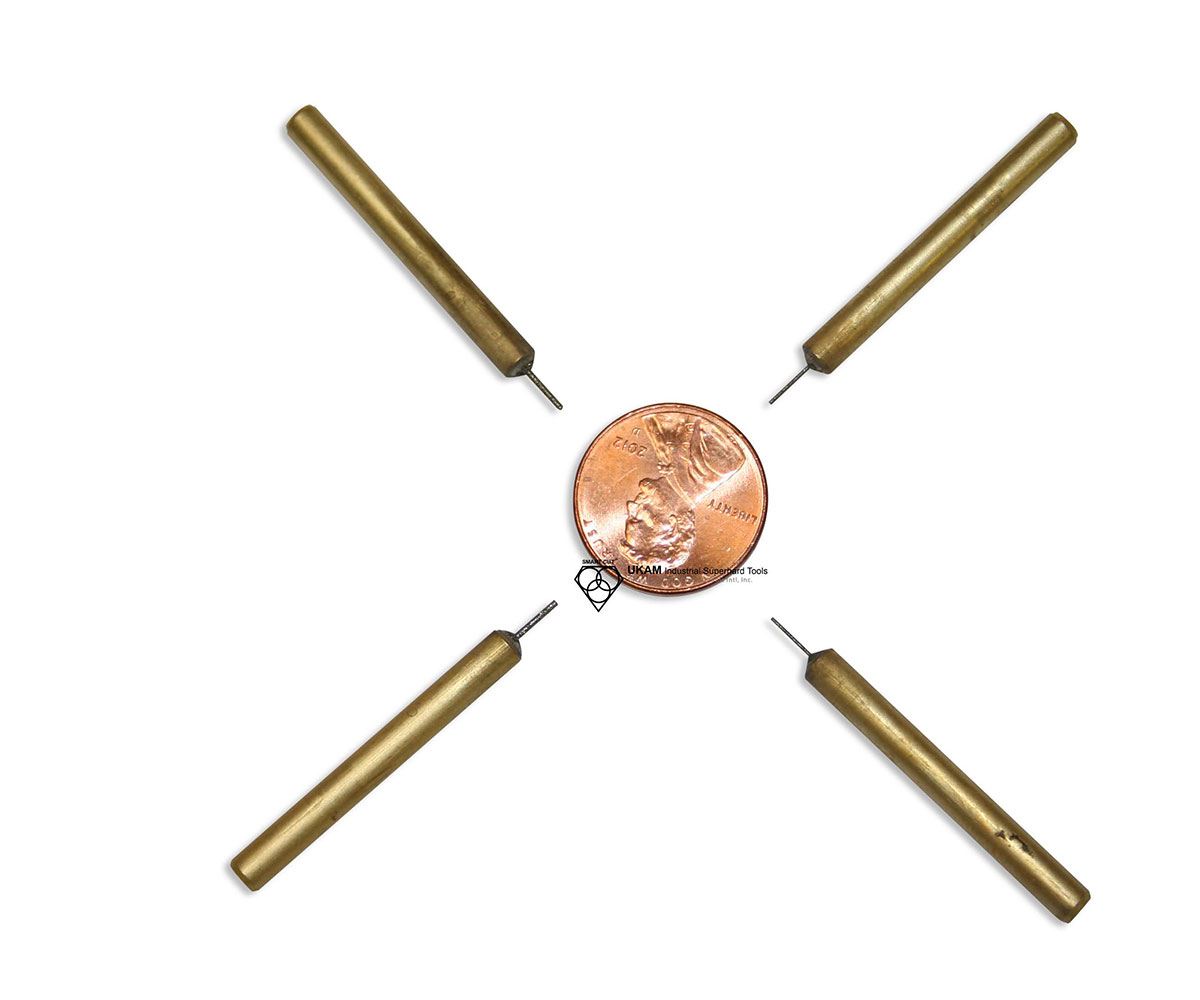

Drilling Photonic Materials

Diamond Core drills & diamond drills from .001" to 48" Diameter, & Drilling Accessories for drilling just about any Material/Application. Diamond Drills are available from inventory in many different specifications. Custom Manufacturing to fit your particular requirements with 1 week or less lead time (non minimum order). We will work with you to determine your needs, and recommend the right solution for your specific application.

Diamond Drill & Diamond Core Drill Specifications Available:

- Diameters Available: .001” to 20 OD

- Drilling Depths: .015” to 36”

- Bond Types: sintered (metal bond), nickel bond (plated), brazed bond,

- Tolerances: + / - .004” on core drills (+ / - .0005” custom)

- Diamond grit sizes: 25 mesh to 3 microns

- Diamond concentration: low, medium & high (from 10 con to 150 con)

- Mounting types: straight shank to your spec, 5/8-11”, 5/8-18”, ¾-16”, ½” gas male, 1-14”, habit, and many others

Solutions

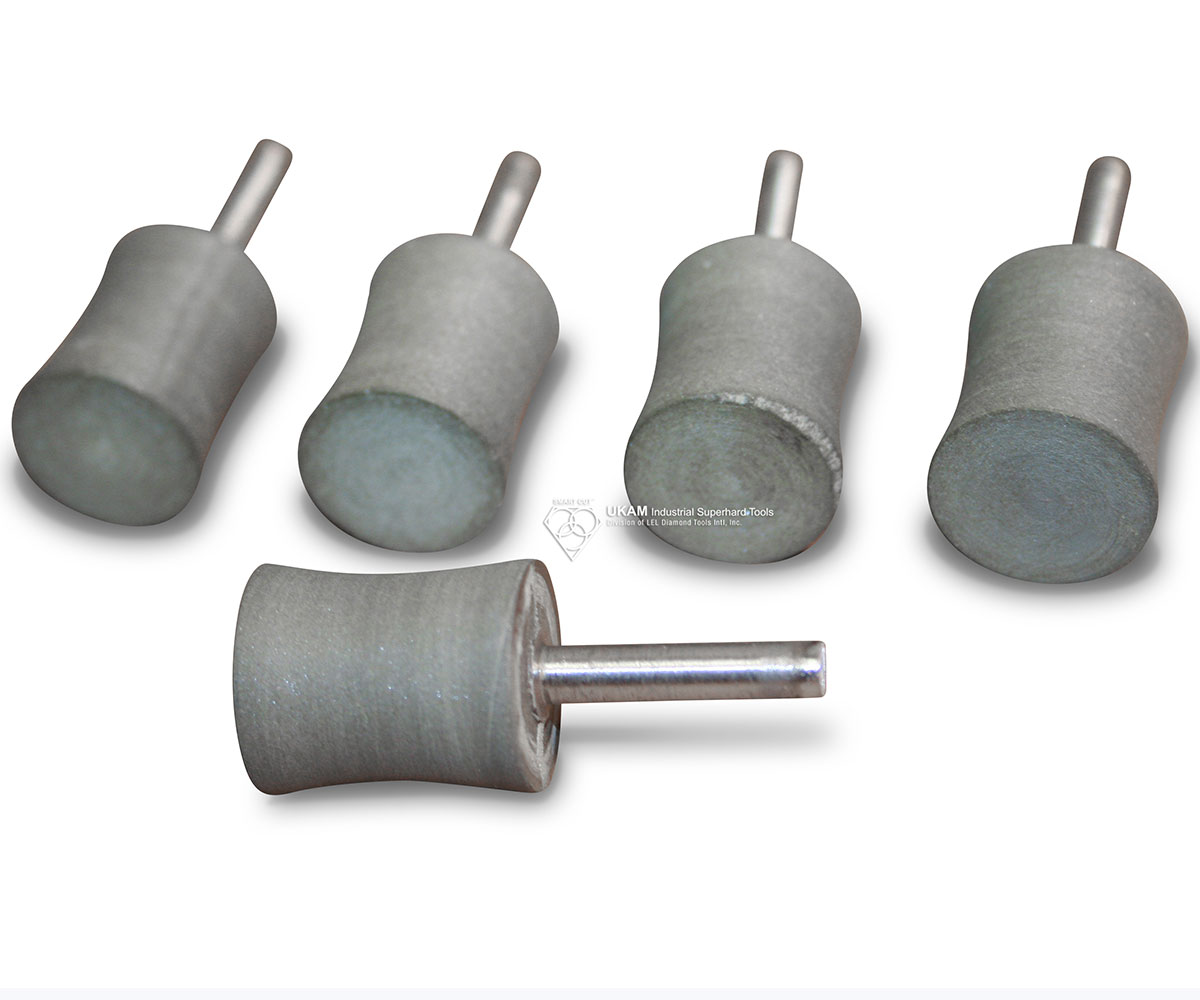

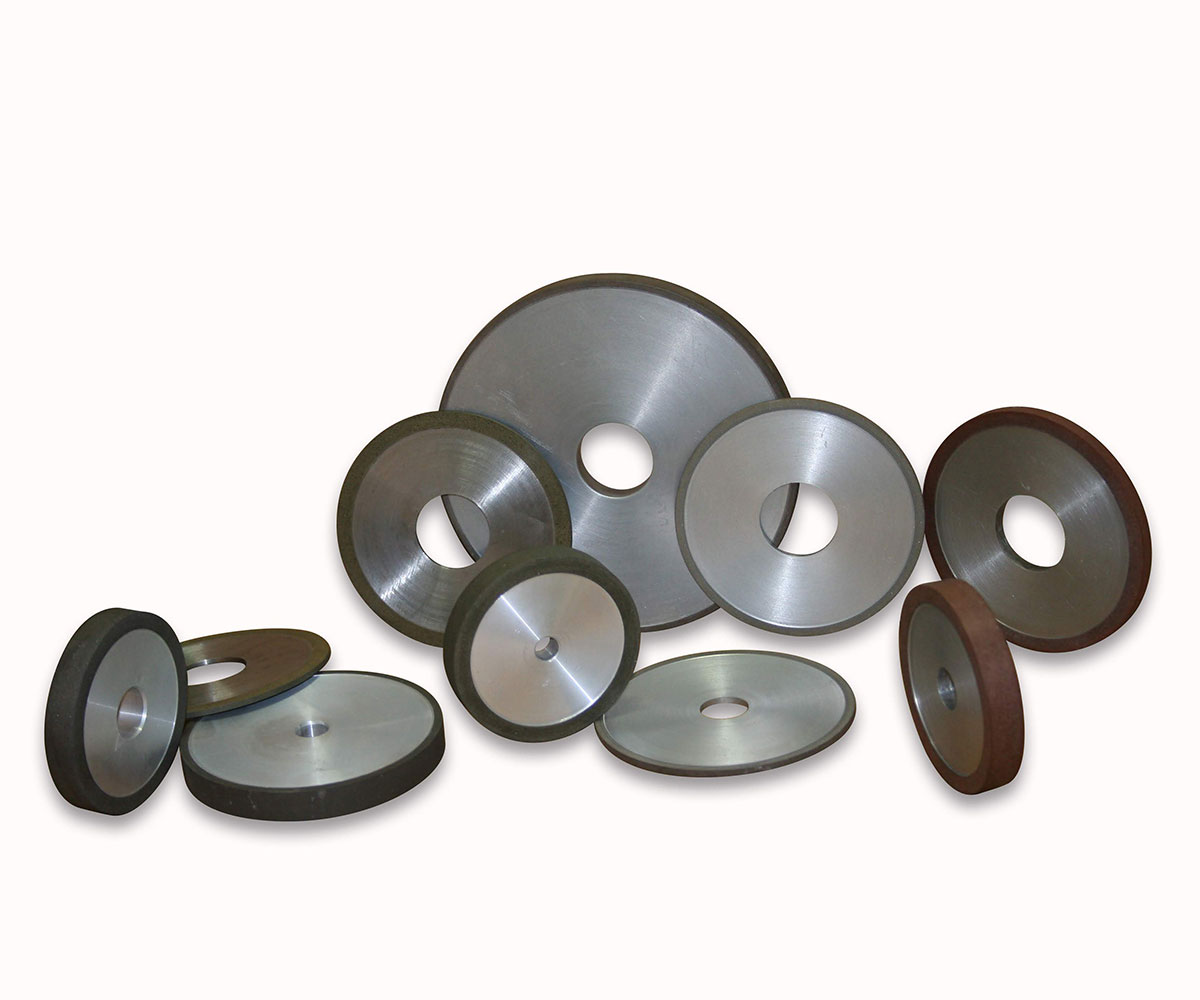

For Machining Photonic Materials

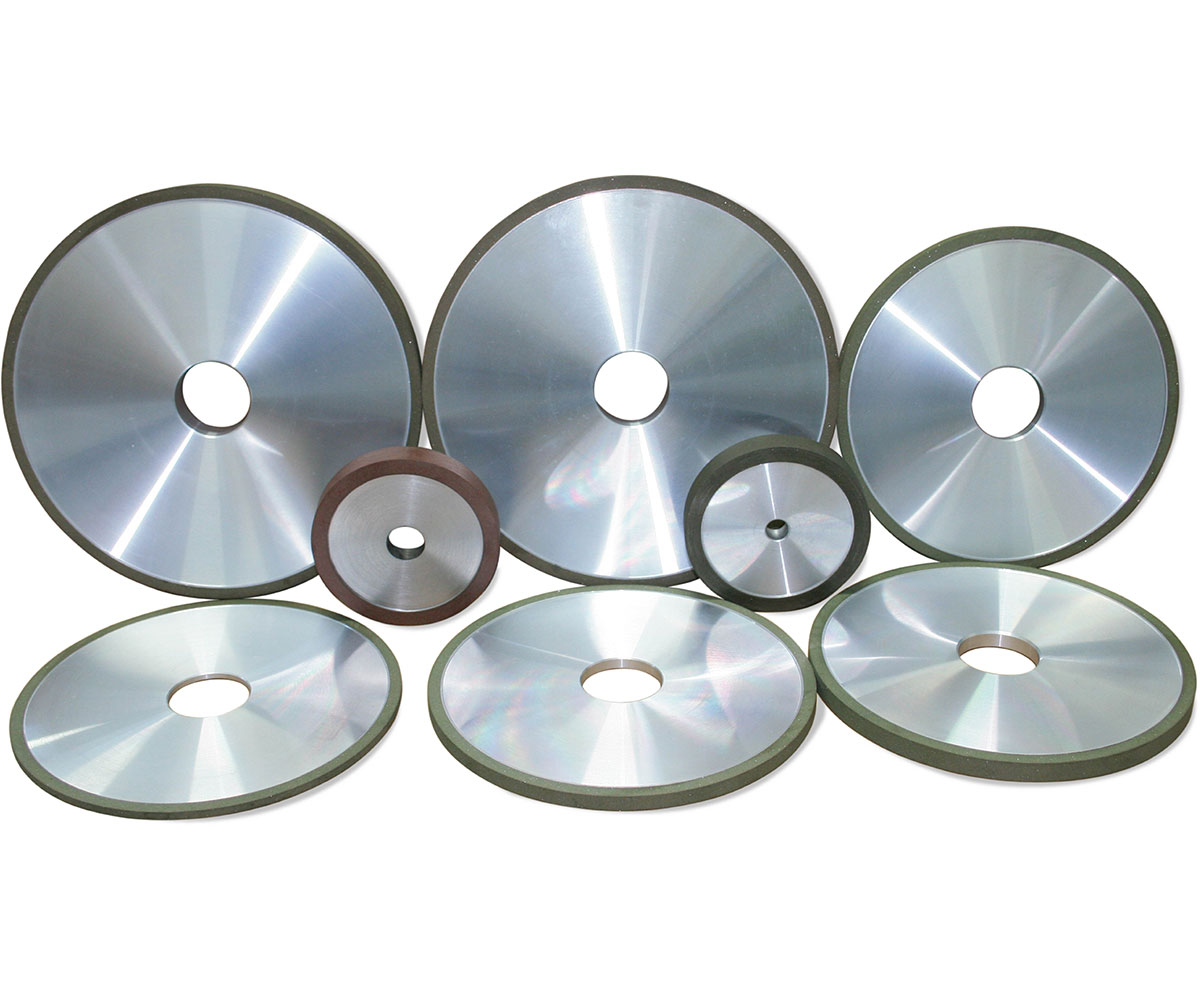

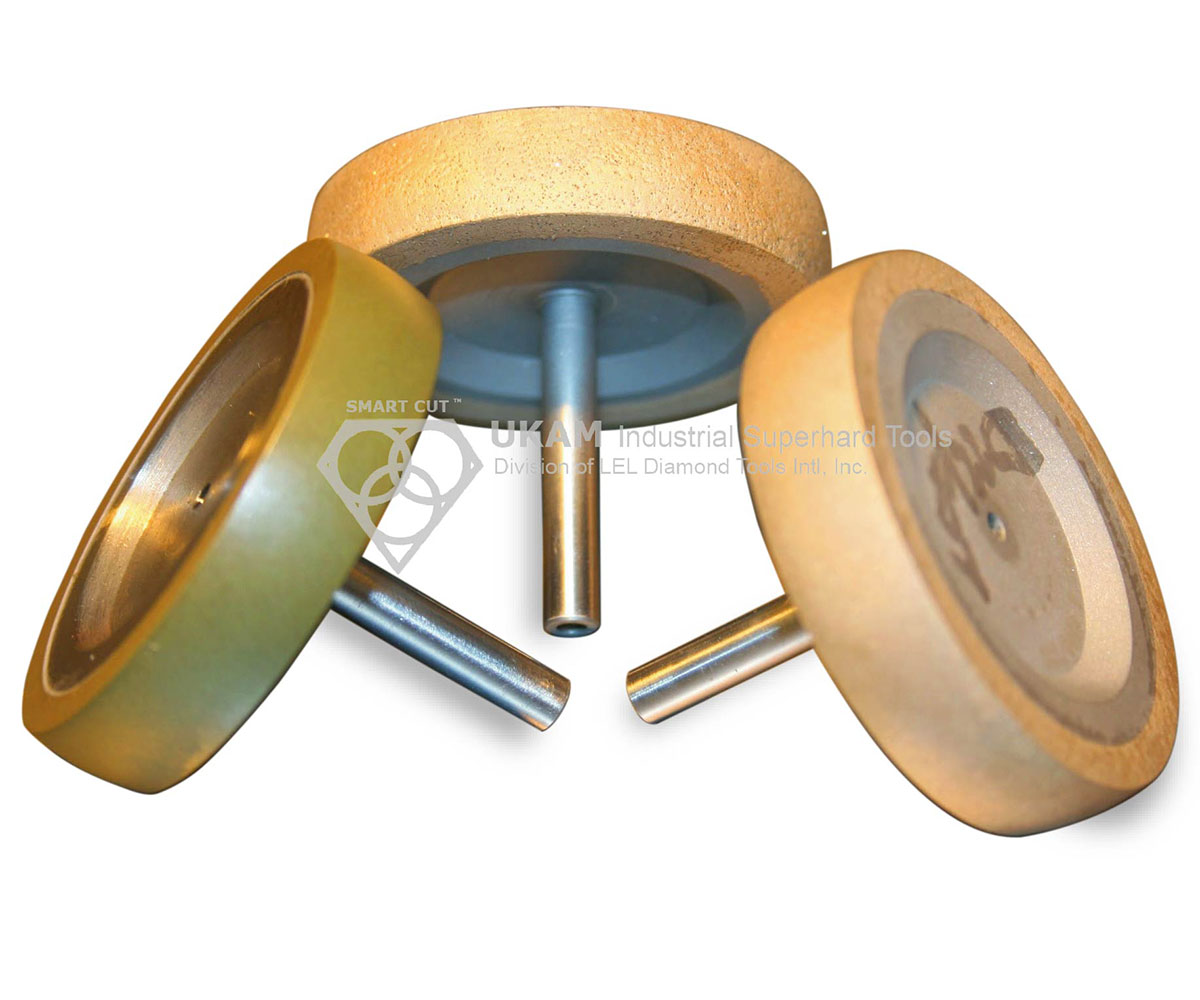

Diamond Optical tools for most grinding and finishing applications. Diamond Optical wheels cut lens material quickly, cleanly with minimal wear. We design and produce laps cut to special radii for optics, grinding and polishing of precision optics are available. Custom shapes are available such as grooved tools, tools with special threads. form tools, and other custom tooling. B+S Univ. Grinder, Strasbaugh Edge Grinder, SAIDA Edge Grinder, GMN MPS Bach Grinder, SPEEDFAM, Lapmaster, Nord-Universal and many others.

SOLUTIONS FOR

Polishing Photonic Materials

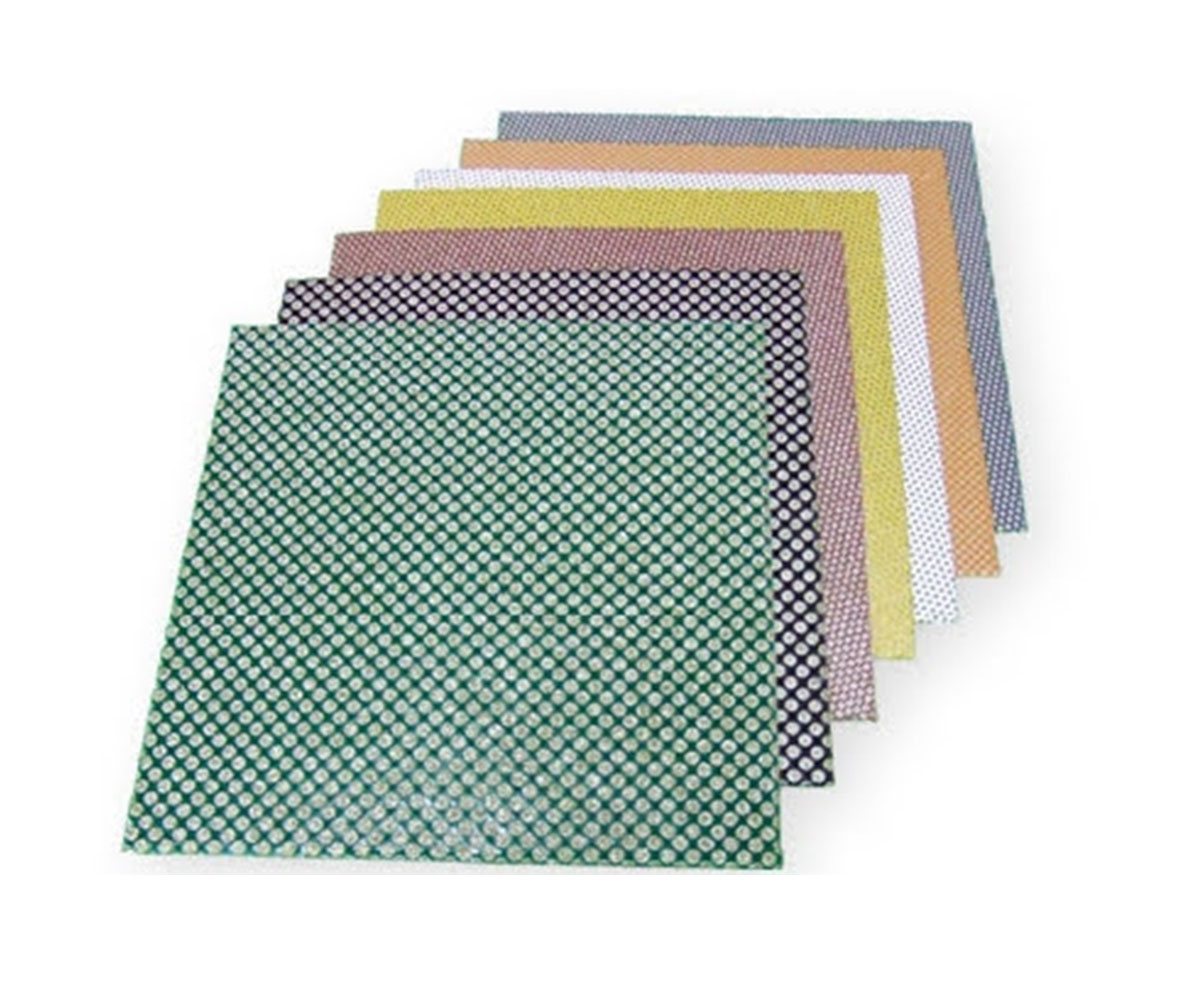

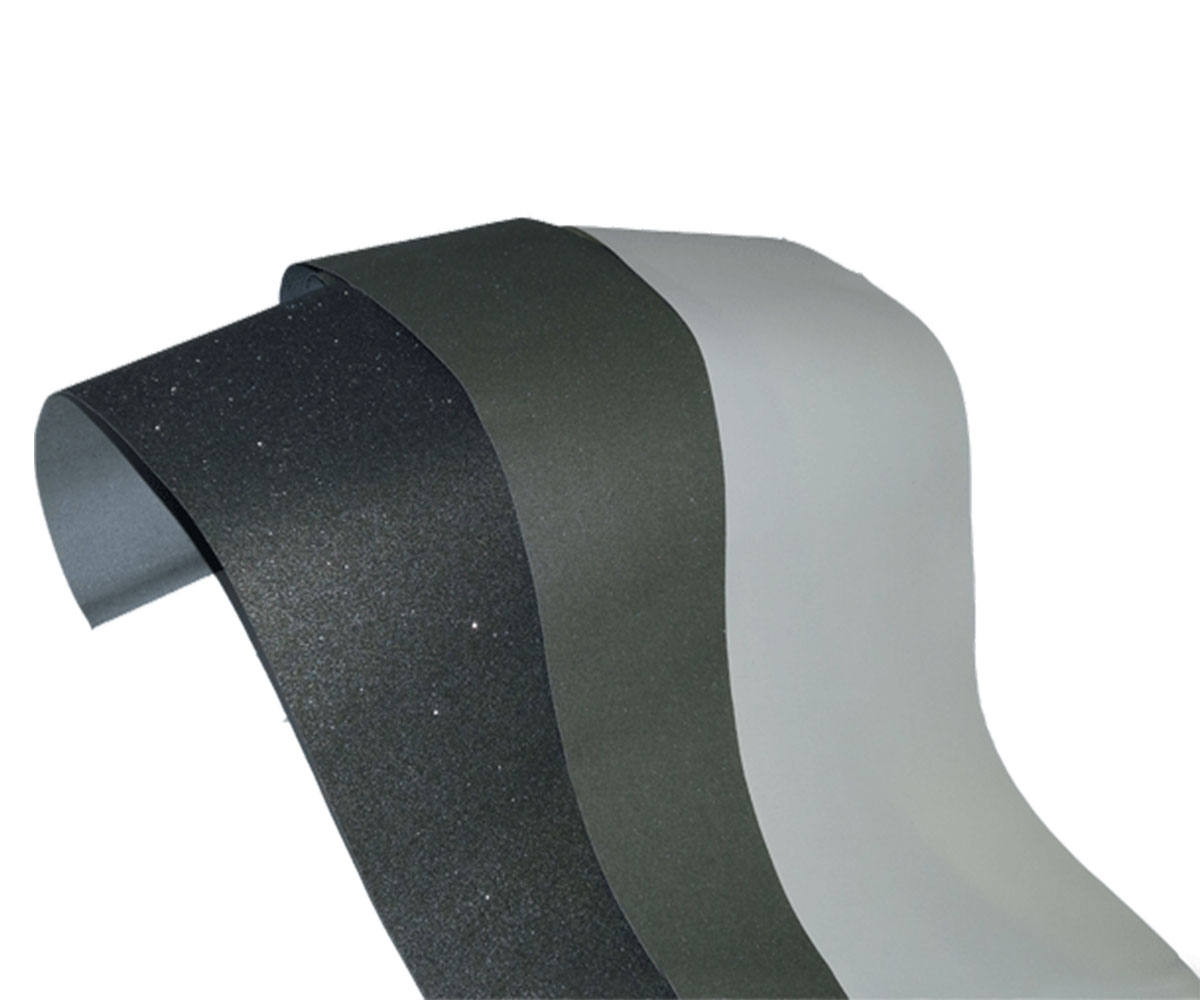

- Diamond Fixed Abrasive Discs

- Diamond grinding/polishing strips/foils

- Diamond film

- Diamond pellets

- Diamond belts

- Polishing Pads

Diamond Consumables

For Photonic Materials

- Diamond Suspensions - Polycrystalline, Monocrystalline, & Natural

- Diamond paste - Polycrystalline, Monocrystalline, & Natural

- Diamond micro powder - Polycrystalline, Monocrystalline, & Natural

- Diamond Spray - Polycrystalline, Monocrystalline, & Natural

PRECISION ABRASIVES

For Photonic Materials

Abrasive Cut Off Wheels, Abrasive Discs, Abrasive Rolls/Strips, Abrasive Belts, Silicon Carbide (SIC), Zirconia Alumina (ZA), Aluminum Oxide (ALOX), Grinding Wheels - (Aluminum Oxide and Silicon Carbide), Lapping Films (Plain Backed & PSA Backed, Felt Polishing Pads

GRINDING/POLISHING EQUIPMENT

For Photonic Materials

6" to 24" (150mm to 609mm) diamond grinding, polishing, & lapping machines for Industry and R & D. Designed coarse & fine grinding and polishing of Advanced, Ultra Hard & Brittle Materials, Optical Materials, Composites. High hardness materials including

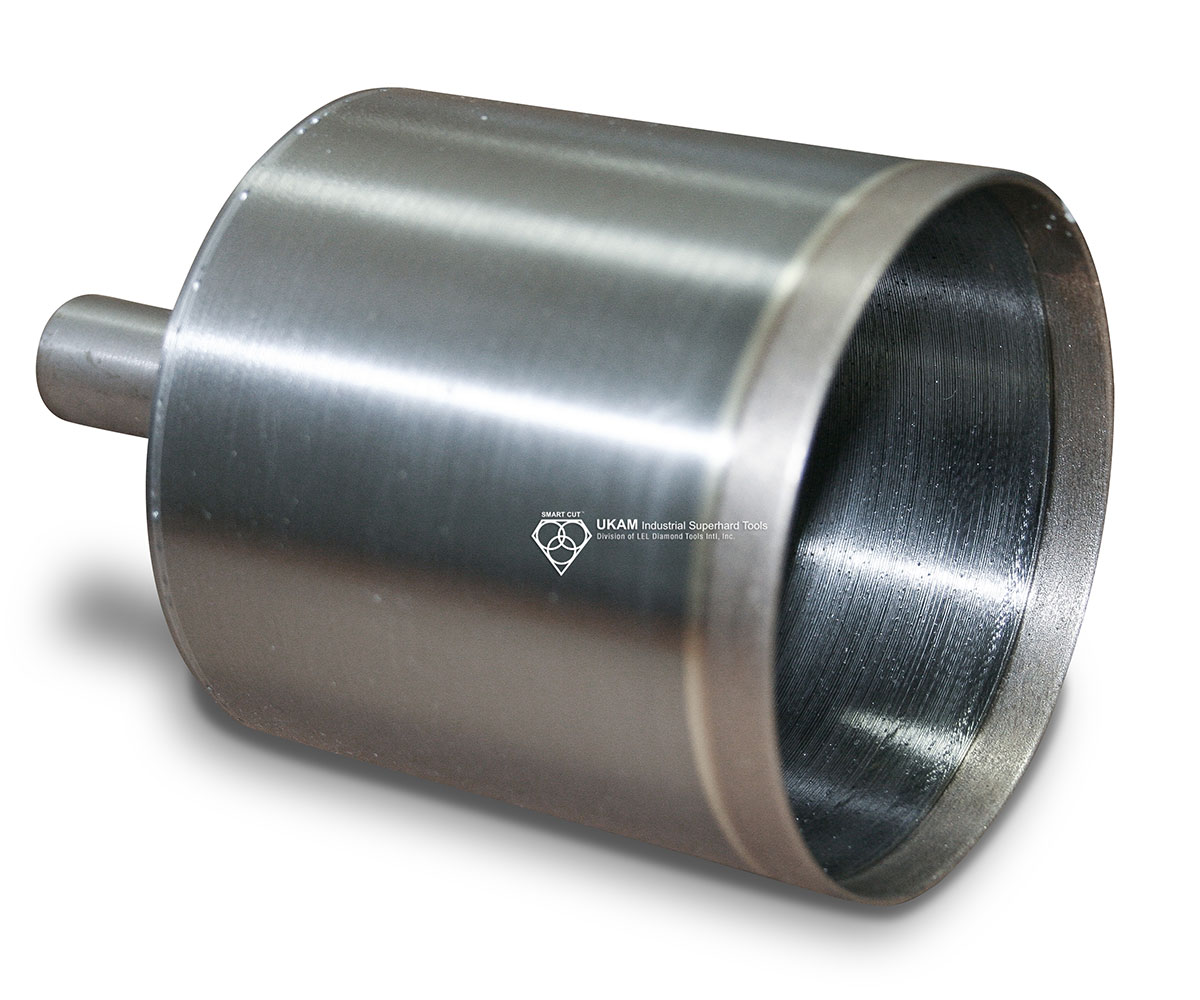

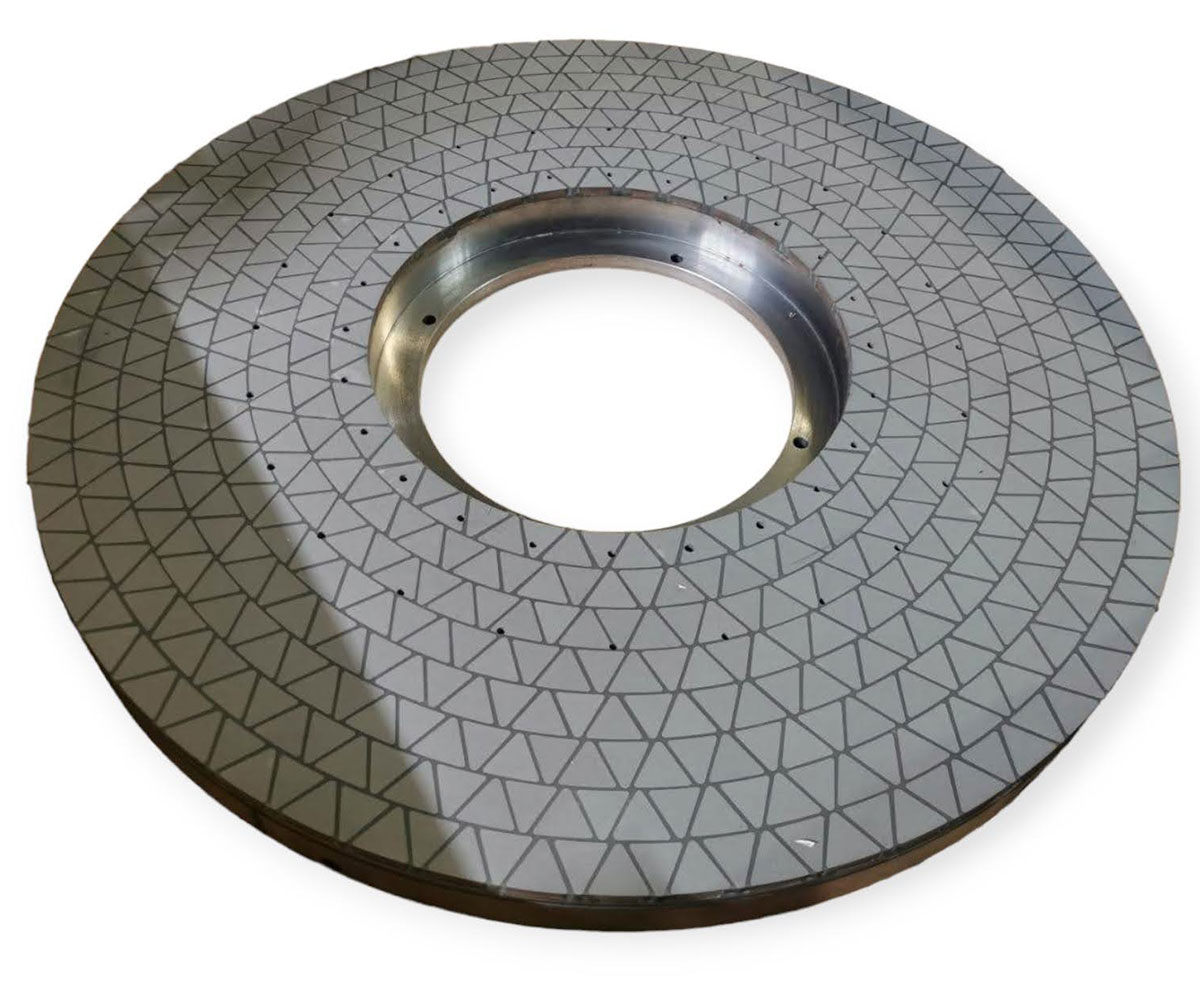

Example of

Custom Diamond Tool for Photonics

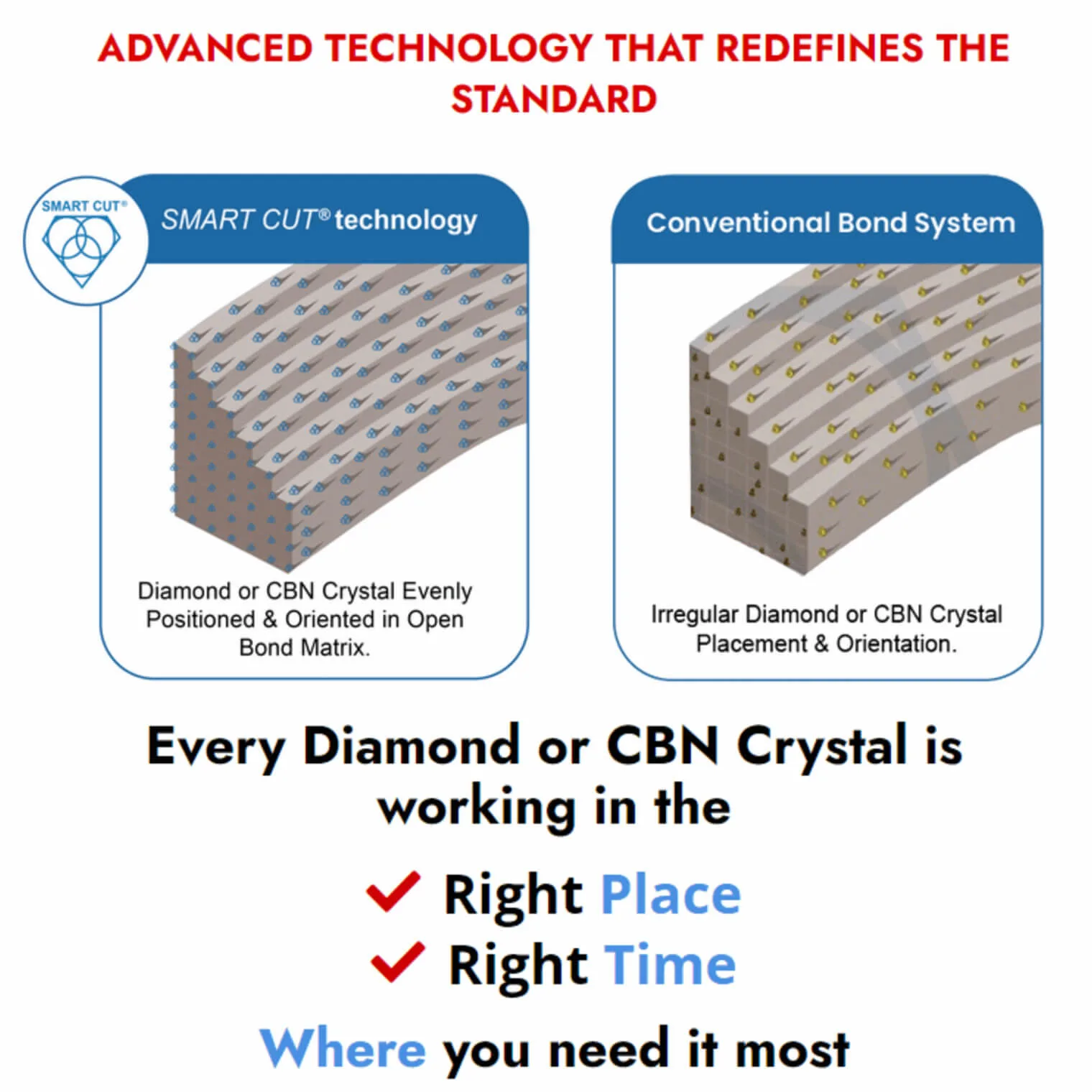

ITS WHAT YOU CANT SEE THAT MAKES ALL THE DIFFERENCE

SMART CUT® technology

We can help you:

Advanced technology that allows every diamond to be oriented and evenly positioned inside diamond bond matrix. Every diamonds works in the right place and at the right time, where you need it most

- Improve Tool Life

- SAVE TIME & MONEY

- Obtain More Consistent Results

- Improve Surface Finish

- Preserve True Material Microstructure

- Reduce & eliminate Material Deformation

- Improve Consumable Life & Overall Performance

Why Work With Us?

Comprehensive Source Of Information For Diamond Tools

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

Large Inventory & Custom Manufacturing

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

Umatched Technical Support

We Are A Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Advanced

Technology

AMERICAN MANUFACTURER

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Superior Quality & Consistency

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

EXPECT MORE FROM YOUR TOOLS

Experience Makes All

The Differences

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years