Diamond Blades For Composites Industry

Composites Industry

Diamond Blades

Leading Manufacturer of High Precision & Ultra Thin Diamond Blades 0.5" (12.7mm) to 48 (1219mm) in Outside Diameter, starting from 004 (0.1mm) Thick.

For cutting just about any type of composite materials Precision Diamond Blades are available from inventory in many different specifications, diamond concentrations, mesh sizes, bond hardness, & inside diameters. Custom Manufacturing to fit your requirements of almost any blade specification, with small or minimum order quantities & fast lead times.

Diamond Blades for

Composites Industry

Composite Materials

- Resin

- Aramid

- Carbon Fibers

- Boron

- E-Glass

- S-Glass

- Al2O3

- Aluminium

- Graphite

- Fiber

- SiC

- Si3N4

- Honeycomb

- Titanium

- Diboride

- Normex Honeycomb

- Hormex Honeycomb

- Silicon Carbide Fibers

- Polymer Matrix Composites

- Metal Matrix Composites

- Thermoplastic Honeycomb

- FRP Composite

- Ceramic Matrix Composites Graphite

- Many Others

Minatare & Small Diameter

Blades for Composites

Minature Diamond Cutting Wheels

Used on: rotary hand pieces such as Dremel, Foredom, Die Grinders, Milling Machines, & other machinesUsed for cutting, slotting, grinding & polishing large composite materials. Diameters available from 18mm to 3.0”.

Thicknesses from .040” to .250”. Arbor size from 1/16” to 1.25” or with mandrel. Bond types sintered (metal bond), resin bond, nickel bond, braised bond

Small Diameter, Continuous Rim (plated)

Continuous rim diamond cutitng blades are used for dry cutting of larger variety of composite materials, fiberglass, plastics and other soft and gummy materialsDiameter: 1″ to 16″

Arbor hole: as per your specifications

Thickness: 1/16″ to 5/32″, as per your specifications and depending on diameter

Grit: 35/40, 45/50 or 60/70. Other choices possible

Small Diameter, segmented (plated)

Slotted, plated diamond cutting blades are used for dry cutting of larger variety of composite materials, fiberglass, plastics and other soft and gummy materials Diameter: 1″ to 16″

Arbor hole: as per your specifications

Thickness: 1/16″ to 5/32″, as per your specifications and depending on diameter

Grit: 35/40, 45/50 or 60/70. Other choices possible

Diamond Mounted Blades for

High Speed Grinders

MInature, Slitting Blades (plated)

Available from stock from 8mm to 22mm Diameter. These multi layered plated wheels come mounted on shank 3mm diameter. Kerf thickness .026” to .039”. These are designed for cutting and grinding large variety of hard to soft materials.

Small Diameter, Mounted Blades (plated)

Mounted electroplated diamond trimming blades. These blades are used where it is necessary to cut close into a corner. The diamond blade and spindle are made in one piece and present a flush side to the work. Special shank sizes available upon request.

Small Diameter, Mounted Blades (Braised Bond)

Braised bond diamond trimming blades, can be mounted on one of our arbors. These blades are used where it is necessary to cut close into a corner. Special shank sizes available upon request.

Braised Bond Diamond Cut off Blades

Smaller diameter braised bond cutting blades are used on large variety of cutting equipment for Cutting large variet of hard to soft Materials. Available from 4” to 10” Diameter from stock. These blades are desgined for fast and rough cutting for dry application. Can replace conventional abrasive cut off blades

Braised Bond Slabbing Blades

Braised bond slabbing blades are used on larger cutting machines, slab saws & other equipment for Cutting large variet of hard to soft Materials. Available from 12” to 36” Diameter from stock. These blades are desgined for fast and rough cutting for dry application. Can replace conventional abrasive cut off blades

Slabbing Blades, sintered (metal bond)

Used on larger cutting machines, slab saws & other equipment for Cutting large variet of hard to soft Materials. Available from 18” to 36” Diameter from stock. Continuous rim, narrow spacing between the segments and wide segment spacing. Thicknesses from .085” (2.15mm) to .125” (3.2mm). Standard arbor size is ¾ and 1”. Arbor size can be modified to anything you want same day if needed

Diamond & CBN Cut Off Blades Sintered (metal bond)

Available from stock from 10” (254mm) ot 16” (400mm). Kerf Thickness from .040” (1mm) to .085” (2.2mm). Arbor sizes: ¾”, 1”, 1.25”, 32mm. we can alter the arbor size to anything you want usually same day (if needed). Available in Many Different Grit Sizes, Concentrations & specifications to fit your requirements

Resin Bond Diamond Cut off blades (Medium Size Diamond)

SMART CUT® Series 2000 are the highest quality & most commonly used Resin Bond Diamond Cut off Blades / Cut Off Wheels available today.

Diamond & CBN Cut Off Blades Sintered (metal bond)

Available from stock from 10” (254mm) ot 16” (400mm). Kerf Thickness from .040” (1mm) to .085” (2.2mm). Arbor sizes: ¾”, 1”, 1.25”, 32mm. we can alter the arbor size to anything you want usually same day (if needed). Available in Many Different Grit Sizes, Concentrations & specifications to fit your requirements

Diamond & CBN Cut Off Blades Resin Bond

Available from stock from 10” (254mm) ot 16” (400mm). Kerf Thickness from .040” (1mm) to .085” (2.2mm). Arbor sizes: ¾”, 1”, 1.25”, 32mm. we can alter the arbor size to anything you want usually same day (if needed). Available in Many Different Grit Sizes, Concentrations & specifications to fit your requirements

Diamond & CBN Cut Off Blades Nickel Bond (plated)

Available from stock from in continuous rim and slotted designs from 10” (254mm) to 14” (350mm). Kerf Thickness from .040” (1mm) to 125” (3.2mm). Arbor sizes: ¾”, 1”, 1.25”, 32mm. we can alter the arbor size to anything you want usually same day (if needed). Available in Many Different Grit Sizes, Concentrations & specifications to fit your requirements

Diamond Cut off blade for Advanced Ceramics, Sintered Metal Bond

Smart cut 455M designed for ceremics & glass cutting where minimizing chipping and excellent surface finish is important...

Nickel Bond (plated) Slotted Diamond Cut Off Blades

Available from stock from 10” (254mm) ot 16” (400mm). Kerf Thickness from .040” (1mm) to .085” (2.2mm). Arbor sizes: ¾”, 1”, 1.25”, 32mm. we can alter the arbor size to anything you want usually same day (if needed). Available in Many Different Grit Sizes, Concentrations & specifications to fit your requirements

Nickel Bond (plated) Continuous Diamond Cut Off Blades

Available from stock from 10” (254mm) ot 16” (400mm). Kerf Thickness from .040” (1mm) to .085” (2.2mm). Arbor sizes: ¾”, 1”, 1.25”, 32mm. we can alter the arbor size to anything you want usually same day (if needed). Available in Many Different Grit Sizes, Concentrations & specifications to fit your requirements

Sintered (Metal Bond) Segmented Blades

Available from stock from in continuous rim and slotted designs from 10” (254mm) to 14” (350mm). Kerf Thickness from .040” (1mm) to 125” (3.2mm). Arbor sizes: ¾”, 1”, 1.25”, 32mm. we can alter the arbor size to anything you want usually same day (if needed). Available in Many Different Grit Sizes, Concentrations & specifications to fit your requirements

Diamond & CBN Blades for

Laboratory Application

Diamond & CBN Wafering Blades, sintered (metal bond)

Used On: All Low & High Speed Wafering Saws, Sectioning Saws, Such as Buehler, Struers, Leco, & many others. SMART CUT™ Precision New Generation Sintered (metal bonded) Diamond & CBN Wafering Blades are the most widely used type of wafering blades for almost all materials and applications. Available from stock from 3” (75mm) to 8” (200mm). Thicknesses range from .004” (100 microns) to .035” (0.8mm). Stadard arbor size is ½” (12.7mm). arbor size can be modified to anything you want usually same day. Large Variety of diamond & cbn grit sizes, concentrations, bond hardnesses. Choose from 21 different blades, including 5 different diameters and high or low concentrations to fit almost any application (Series 30HCU to 5LCU)

Diamond & CBN Wafering Blades, Resin Bond

Used On: All High Speed Wafering Saws, Sectioning Saws, Such as Buehler, Struers, Leco, & many others. Can be used on lower speed cutting machines if RPM’s are above 1,000. Available from stock from 4” (100mm) to 8” (200mm). Thicknesses range from .015” (0.38 mm) to .035” (0.8mm). Stadard arbor size is ½” (12.7mm). arbor size can be modified toanything you want usually same day.Recommended for applications where cut quality and surface finish is very important. Resin Bond Diamond & CBN Waferings offer far superior cut quality than the finest size metal bond (sintered) bade. Most commonly used at higher speeds

Diamond & CBN Wafering Blades, Nickel Bond

Used On: All Low & High Speed Wafering Saws, Sectioning Saws, Such as Buehler, Struers, Leco, & many others.Available from stock from 4” (100mm) to 8” (200mm). Thicknesses range from .010” (0.25 mm) to .035” (0.8mm). Stadard arbor size is ½” (12.7mm). arbor size can be modified to anything you want usually same day. Nickel Bond Diamond & CBN Wafering Blades usually have a single layer of diamonds, held by a tough durable nickel alloy. diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation. Recommended for cutting softer and more gummy materials, where sintered (metal bond) diamond wafering blades load up or glaze over frequently.

Other

Blade Types

Diamond Wire Blades

Diamond Wire for almost all laboratory and larger diamond wire saws. Used for cutting large variety of ultra hard to soft materials. Available in diameters from 0.1mm to 3mm thickness. Made for your application. From Loops short as 84cm to spools hundreds of meters long

Diamond Band Saw Blades

Diamond Band Saw Blades are used for cutting large variety of ultra hard to soft materials wet or dry. Available to fit just about any type of Band Saw Machines. Starting from .020” (0.5mm) to .040” (1mm) thickness. Widths from ¼” to 1.5”. Length any from 36” and up. Blades are available from stock on spool and cut and welded to any length. Diamond Grit sizes available from 35/40 to 120 mesh.

Ultra Thin & High Precision Carbide Blades

Ultra thin, fine teeth tungsten Carbide blades are available from 3” (75mm) to 8” (200mm) OD, thickneness from from .004” (100 microns). Standard arbor is ½”, but can be made any size. Ttypically used on low speed cutting machine. Typical application are materials where diamond cannot be effective used such as green ceramics, PC Board substrates, fiberglass, laminates, MLP/QFN, and similar materials

Accessories

Coolants

SMART CUT water soluable coolants & Mineral oils are are designed for use on all high and low speed sectioning/wafering saws, laboratory/abrasive cut off saws. Such as Buehler, Struers, Leco & many others. SMART CUT Enviromental Friendly & Non Hazardous Coolants help reduce amount of heat generated while sectiong and provides needed lubrication to blade and sample being cut. Its usage will help increase Blade Life, Reduce Material Damage or micro cracks associated with overheating, Improve Cutting Speed, Improve Surface Finish, MinimizeChipping, Preserve Material microstructure

Dressing Sticks

Dressing Sticks are available from stock to fit all types of diamond, cbn, abrasive wafering & cut off blades and sectiong saws. Such as Buehler, Struers, & Leco. Available in different sizes, grits, and abrasive types

Blade Stiffeners

Wheel Stiffeners provide stability, rigidity & additional support for your blades. They help in prventing the blade from loosing wobbling and loosing its fltantess or breaking. They are placede between your existing flanges to reduce the blade exposure. Wheel Stiffeners are made to order can can be any diameter, thickness or arbor size to fit any type of cutting machine such as Buehler, Struers, Leco & many others . Lead time is few days.

Precision Arbors

Precision arbors ½” (12.7mm) and 5/8” (15.75mm) diameter to fit many different type of cutting machines and cutting blades. Use in conjunction with our flanges and wheel stiffeners

Flanges

Flanges are designed to add additional support and stability to both sides of the blade. Flanges prevent the blade from losing its tension & warping, losing flatness, blade wreckage, slanting cuts, damage to material and much more

Precision Cutting Service & Process Development

We offer large variety of of services including: Dicing, Slicing, Sectioning, Drilling, Coring, Micro Drilling, Grinding, Polishing, & Machining

ITS WHAT YOU CANT SEE THAT MAKES ALL THE DIFFERENCE

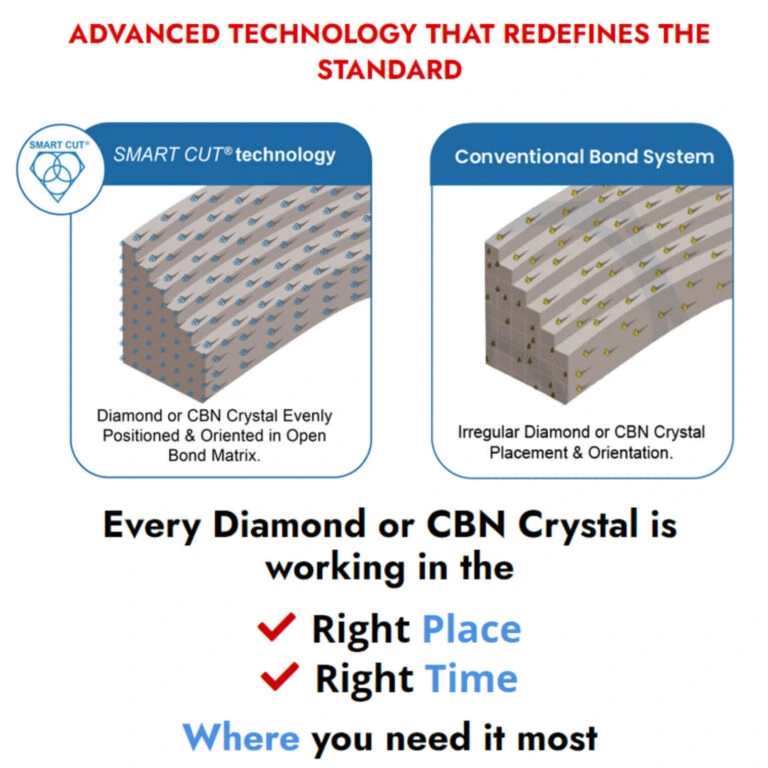

SMART CUT® technology

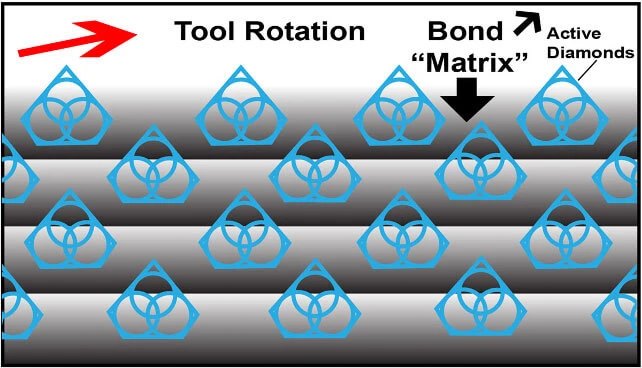

How SMART CUT ® Bond Works?

Sharpest And Finest Quality Diamonds

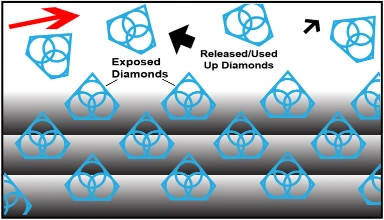

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Why Work With Us?

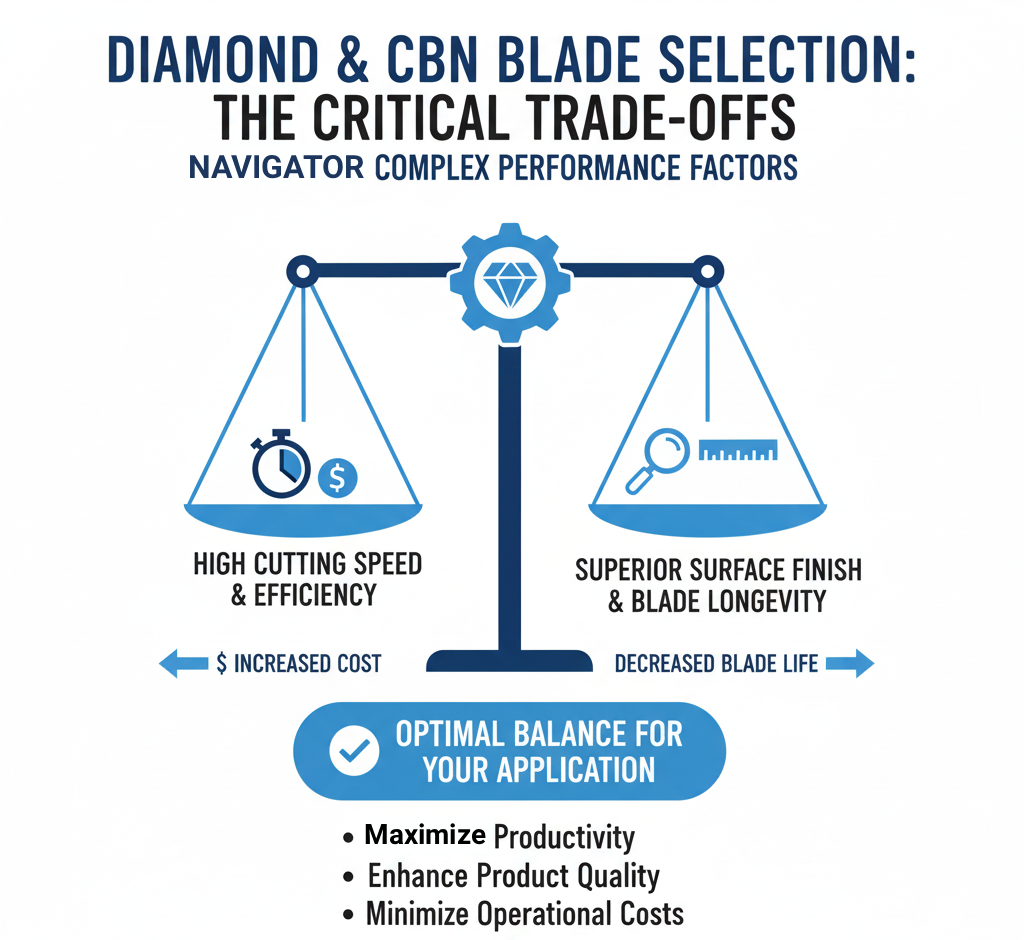

Comprehensive Source Of Information On Dicing Blades

We understand that your success depends on select the right dicing blade, and optimizing your dicing parameters to best fit your applications/needs. The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

WE ARE A PARTNER IN YOUR SUCCESS

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

AMERICAN MANUFACTURER

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality & Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency.

EXPECT MORE FROM YOUR TOOLS